I left the key in the ON position last night on my L175 and today when I tried to start it, the battery was dead. I tried jumping it using my VW Vanagon. It was turning over and almost started then nothing. The glow plug light is on but when I turn the key nothing happens. Did I fry the starter? This is my first tractor. The owners manual doesn't help. Is it hard to replace a starter? I'm a girl, but I did take Auto Shop in high school.

Did I fry my starter?

- Thread starter brigitte

- Start date

No click when you try to turn the engine over?

Did you by chance bump a lever when you were trying to jump it and a safety switch is tripped?

The next step is to do a voltmeter test at the main positive connection at the starter solenoid, then at the starter side of the solenoid when attempting to crank. If you have 12v+ at the starter side of the solenoid and no cranky, then either the starter is dead or the engine is locked up.

Hint, do not attach the ground lead of the voltmeter to the negative post of the battery, go to a good ground on the engine that way you will also test for a poor ground connection in the lead from the battery to the chassis / engine.

Post what you find and we can all go from there.

David

Did you by chance bump a lever when you were trying to jump it and a safety switch is tripped?

The next step is to do a voltmeter test at the main positive connection at the starter solenoid, then at the starter side of the solenoid when attempting to crank. If you have 12v+ at the starter side of the solenoid and no cranky, then either the starter is dead or the engine is locked up.

Hint, do not attach the ground lead of the voltmeter to the negative post of the battery, go to a good ground on the engine that way you will also test for a poor ground connection in the lead from the battery to the chassis / engine.

Post what you find and we can all go from there.

David

You didn't fry it. The battery is dead and the jump you tried didn't carry enough voltage for it to start.

You have three options:

1. Charge the battery

2. Try to jump it again making double sure you have really good connections and rev the VW to about 2,000 rpms while someone cranks the tractor.

3. Replace the battery (if the battery sits dead for too long it will expire). Doubtful this will be necessary unless the battery was already on its way out.

You have three options:

1. Charge the battery

2. Try to jump it again making double sure you have really good connections and rev the VW to about 2,000 rpms while someone cranks the tractor.

3. Replace the battery (if the battery sits dead for too long it will expire). Doubtful this will be necessary unless the battery was already on its way out.

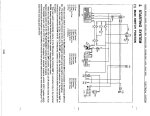

Here is a schematic for the BX. It probably is similar to most tractors.

I'd check the two safety switches, 5 and 6 since they are in the circuit, Also look at the 50 amp fuse. Another possibility is a poor battery connection.

I'd check the two safety switches, 5 and 6 since they are in the circuit, Also look at the 50 amp fuse. Another possibility is a poor battery connection.

Attachments

-

95.1 KB Views: 640

More then likely the jump from the VW bus wasn't enough to give the tractor a swift kick in the ass to turn over. Diesels are a hard engine to jump start and require alot of amps off the boosting vehicle. See if a neighbor can lend a hand from a pickup truck.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Pull the battery out and take it to an auto parts store and have it tested.

If you don't have one get a battery charger with boost.

Do you have a Multi meter or a test light?

If you don't have one get a battery charger with boost.

Do you have a Multi meter or a test light?

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

There are few safety switches on the L175. The only one I am aware of is the clutch pedal switch. You may want to verify that it is being properly operated when you push the clutch down.

I assume you did have the clutch pressed down FULLY when trying to crank it.

To make it a bit easier to crank there are a couple of hints I can suggest that work on my L185 (similar) tractor. Connect the positive jumper cable directly to the starter solenoid, same stud as the red battery cable goes to. It is easily accessed on my tractor on the starter.

The jumper cable ground can then be connected to the engine block or frame. This arrangement will basically bypass the "dead" battery.

I also assume you are using the decompression knob which makes it easier to spin the engine up to speed.

Also - you stated "turn the key". Does you tractor start from the key or is it a black knob? Some wiring may have been redone on your tractor?

I assume you did have the clutch pressed down FULLY when trying to crank it.

To make it a bit easier to crank there are a couple of hints I can suggest that work on my L185 (similar) tractor. Connect the positive jumper cable directly to the starter solenoid, same stud as the red battery cable goes to. It is easily accessed on my tractor on the starter.

The jumper cable ground can then be connected to the engine block or frame. This arrangement will basically bypass the "dead" battery.

I also assume you are using the decompression knob which makes it easier to spin the engine up to speed.

Also - you stated "turn the key". Does you tractor start from the key or is it a black knob? Some wiring may have been redone on your tractor?

Last edited:

gpreuss

New member

Lifetime Member

Equipment

L3200DT w/FEL, K650 Backhoe, 5' Rotary, 40" Howard Rotavator, 6' Rhino blade

Leaving the key on overnight should not really do anything. The oil pressure light on the dash will light, but a good battery should handle that overnight. Possibly the lights were on and you didn't know it?

Do like the wolfman says, but maybe in the opposite order. Invest in a battery charger with a 30 amp boost - you should be able to find one for about $40 - $80. Harbor freight is a good place to start for inexpensive. Investing in an inexpensive volt-ohm-meter is also a good idea.

Check the battery voltage with a meter and write it down, then charge the battery at 8-10 amps for an hour or so with the key off. Write that down, too. Turn on the key, and see if the tractor will at least kick over. Probably it will start.

A good battery will read about 12-13VDC when you first disconnect it from the charger. With the tractor running about 1500 rpm you should see 13-14VDC.

I'd run the tractor for an hour or so, or leave it on the charger for another hour, then take the battery to a shop for testing.

Keep us all informed how you make out.

Do like the wolfman says, but maybe in the opposite order. Invest in a battery charger with a 30 amp boost - you should be able to find one for about $40 - $80. Harbor freight is a good place to start for inexpensive. Investing in an inexpensive volt-ohm-meter is also a good idea.

Check the battery voltage with a meter and write it down, then charge the battery at 8-10 amps for an hour or so with the key off. Write that down, too. Turn on the key, and see if the tractor will at least kick over. Probably it will start.

A good battery will read about 12-13VDC when you first disconnect it from the charger. With the tractor running about 1500 rpm you should see 13-14VDC.

I'd run the tractor for an hour or so, or leave it on the charger for another hour, then take the battery to a shop for testing.

Keep us all informed how you make out.

Lots of good advice thus far; I'd like to add one thing to consider.

Known fault on particular older Kubotas is the negative battery cable connection to chassis ground.

Remove both cables one at the time and check for corrosion on battery terminals. Check also for corrosion, splits, swelling, broken wires, or other damage to both battery cables. Replace with same 'size' or gauge--not smaller--cable if needed.

Remove negative terminal from battery,

remove positive terminal from battery,

clean positive terminal,

reattach to battery,

remove negative from chassis and clean bolted connection vigorously, reattach negative to chassis with conductive thread lube (Kopr-Kote or similar),

clean terminal end of negative and reattach to battery.

It might be that even when jumping from another vehicle any corrosion present prevents sufficient current flow through the entire system to get a start on the tractor.

Depending on your particular battery and its age, a good maintenance practice (particularly going into spring-summer use season) is to check the electrolyte level in the battery. Refill as necessary with distilled water only. Do not overfill and leave space to reinstall the cap(s). Note some batteries are sealed and cannot be refilled. Clean top of battery before removing caps. Be aware of sulfuric acid---caution, but not something that should prevent your maintaining the machine. Do not add water if freezing temps are expected; run machine or charge battery after refilling.

Many people use a glob of grease on their battery terminals to reduce future corrosion. I've used for decades a thick paste (like peanut butter) of plain baking soda and water glopped on both battery terminals. Let it dry overnight. Wash it off once a year and do it again. Nice clean terminals.

Your gender is irrelevant to most everybody on this forum. What matters is that you're smart enough to ask good questions and consider possibilities while taking care of your machine.

Please post back your experiences so we may all learn.

Known fault on particular older Kubotas is the negative battery cable connection to chassis ground.

Remove both cables one at the time and check for corrosion on battery terminals. Check also for corrosion, splits, swelling, broken wires, or other damage to both battery cables. Replace with same 'size' or gauge--not smaller--cable if needed.

Remove negative terminal from battery,

remove positive terminal from battery,

clean positive terminal,

reattach to battery,

remove negative from chassis and clean bolted connection vigorously, reattach negative to chassis with conductive thread lube (Kopr-Kote or similar),

clean terminal end of negative and reattach to battery.

It might be that even when jumping from another vehicle any corrosion present prevents sufficient current flow through the entire system to get a start on the tractor.

Depending on your particular battery and its age, a good maintenance practice (particularly going into spring-summer use season) is to check the electrolyte level in the battery. Refill as necessary with distilled water only. Do not overfill and leave space to reinstall the cap(s). Note some batteries are sealed and cannot be refilled. Clean top of battery before removing caps. Be aware of sulfuric acid---caution, but not something that should prevent your maintaining the machine. Do not add water if freezing temps are expected; run machine or charge battery after refilling.

Many people use a glob of grease on their battery terminals to reduce future corrosion. I've used for decades a thick paste (like peanut butter) of plain baking soda and water glopped on both battery terminals. Let it dry overnight. Wash it off once a year and do it again. Nice clean terminals.

Your gender is irrelevant to most everybody on this forum. What matters is that you're smart enough to ask good questions and consider possibilities while taking care of your machine.

Please post back your experiences so we may all learn.

A girl and her tractor is a beautiful thing cept when its broke  ,, Lots of good advice, and please if you don't understand ASK, we joke and tease but you will always find someone that can give you the right answer,,, even though sometimes it aint the ones we want to hear. Oh and pics we lovs pics

,, Lots of good advice, and please if you don't understand ASK, we joke and tease but you will always find someone that can give you the right answer,,, even though sometimes it aint the ones we want to hear. Oh and pics we lovs pics

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

I just wanted to clarify, he was talking about tractor pic's!Oh and pics we lovs pics

Skeets is right. However, he should have mentioned that a number of those here have even less know how than you have displayed even with their apparent lots of tractor time.

Thank you for all the great advice. I bought a battery charger, attached it, so fingers crossed it works. One thing I didn't try yesterday when I was jumping it with my VW is the Decompression knob. The battery is brand new. I bought it less than 3 weeks ago. I was surprised it was dead. There isn't a speck of corrosion on the battery leads. Another thing I didn't do was put the PTO lever in neutral and the controller lever is in the raised position so my tiller is up.

I'll post an update as soon as the battery is done charging.

I'll post an update as soon as the battery is done charging.

Awwww man and here I almost had her thinking I knew what I was talkin about,,,LMAOSkeets is right. However, he should have mentioned that a number of those here have even less know how than you have displayed even with their apparent lots of tractor time.

Brigitte, you make good points in your response.

Leaving the key 'on' probably contributed to finding the new battery dead. If it is warranted by the seller you're ahead of the game. Otherwise, just slowly bring it back to full charge using the lowest setting (perhaps ~2-amps?) on your charger.

All batteries prefer a trickle charge compared to an intense fast charge that generates heat and gasses.

I have a memory from years ago that some VW's had a "positive ground"---confirm how yours works and make certain how your tractor battery is hooked to the VW battery using your jumper cables. If in doubt, switch the VW bat into the tractor to experiment.

Another consideration: the jumper cables themselves may be presenting a problem. I see a lot of itty-bitty jumper cables smaller than your finger--almost pencil size--that are essentially useless. The wire inside the cable is so small it cannot conduct sufficient current to start a high-compression diesel engine.

Not inexpensive but well worth adding to your arsenal is a set of heavy-duty (may be called 'trucker type', 'commercial', or 'oil field') jumper cables. Try online for better prices than parts houses. Box stores may not have them. Some welding supply companies make up HD jumper cables. You want longer ones, too. Sooner or later you'll have to stretch from behind or two parking slots over. Personally, try for #0 (zero, pronounced 'ought') or #00 (odd nomenclature: smaller number, more zeros in this case, is larger cable) copper fine-strand highly flexible welding-type cable, heavy clamps, 20-ft long.

Assuming your decompression pull knob works as intended (recent posters have described cables inoperative due to age and corrosion)---fully depress the clutch to satisfy the safety switch if present (latching the clutch 'down' may not engage the switch), pull the decomp when starting, let the engine spin up for couple seconds, then push the decomp in. Should light right off. Be sure to give your glow plugs time to heat up first.

Another good point you mention is considering all the safety switches: on one of mine the PTO being engaged will prevent a start. Be certain everything on the machine is properly set up so you can get a start without safety switch complications. If in doubt, find the Owner's Manual.

Concerning the tiller, most folks tend to "ground" the implement when shutting down. This prevents inadvertent non-powered lowering that might hurt somebody or land on a sleeping shop cat.

Please continue to post back concerning your ongoing experiences so we may all learn.

Leaving the key 'on' probably contributed to finding the new battery dead. If it is warranted by the seller you're ahead of the game. Otherwise, just slowly bring it back to full charge using the lowest setting (perhaps ~2-amps?) on your charger.

All batteries prefer a trickle charge compared to an intense fast charge that generates heat and gasses.

I have a memory from years ago that some VW's had a "positive ground"---confirm how yours works and make certain how your tractor battery is hooked to the VW battery using your jumper cables. If in doubt, switch the VW bat into the tractor to experiment.

Another consideration: the jumper cables themselves may be presenting a problem. I see a lot of itty-bitty jumper cables smaller than your finger--almost pencil size--that are essentially useless. The wire inside the cable is so small it cannot conduct sufficient current to start a high-compression diesel engine.

Not inexpensive but well worth adding to your arsenal is a set of heavy-duty (may be called 'trucker type', 'commercial', or 'oil field') jumper cables. Try online for better prices than parts houses. Box stores may not have them. Some welding supply companies make up HD jumper cables. You want longer ones, too. Sooner or later you'll have to stretch from behind or two parking slots over. Personally, try for #0 (zero, pronounced 'ought') or #00 (odd nomenclature: smaller number, more zeros in this case, is larger cable) copper fine-strand highly flexible welding-type cable, heavy clamps, 20-ft long.

Assuming your decompression pull knob works as intended (recent posters have described cables inoperative due to age and corrosion)---fully depress the clutch to satisfy the safety switch if present (latching the clutch 'down' may not engage the switch), pull the decomp when starting, let the engine spin up for couple seconds, then push the decomp in. Should light right off. Be sure to give your glow plugs time to heat up first.

Another good point you mention is considering all the safety switches: on one of mine the PTO being engaged will prevent a start. Be certain everything on the machine is properly set up so you can get a start without safety switch complications. If in doubt, find the Owner's Manual.

Concerning the tiller, most folks tend to "ground" the implement when shutting down. This prevents inadvertent non-powered lowering that might hurt somebody or land on a sleeping shop cat.

Please continue to post back concerning your ongoing experiences so we may all learn.

Woooo hooo!!! I got it started! I traced all the wires to the starter and found one that was barely hanging on. I re-attached it and it started better than it ever had before. Thank you all for your awesome advice. I'm a happy girl!

ps. I updated my profile with a pic of my tractor and VW.

ps. I updated my profile with a pic of my tractor and VW.

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Good Job, and Excellent to hear you got it going!

Thanks a VW with a chicken tractor on the roof!

Thanks a VW with a chicken tractor on the roof!

Sorry to hear that Eric,Hers is bigger then mine... I'm jealous!