Cylinder Liners

- Thread starter mwood1129

- Start date

whitetiger

Moderator

Staff member

Equipment

Kubota tech..BX2370, RCK60, B7100HST, RTV900 w plow, Ford 1100 FWA

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

Kubota does not sell kits. They are engine overhaul sleeves and require boring.Generally speaking tractors, gas and diesel are. All the 'kits' for gas tractors are 'matched sets'...NO machining is required. I know the sets for my Buda Diesel are easily 'user installed'.

It sure sounds like that machine shop with an $800 quote is gouging the customer. Ain't no way it'd take 8 full hours to install one sleeve

Pre-finished sleeve kits for old gas engine tractors are commonly available. Melling lists them in their catalog and I do a brisk hobby business manufacturing custom sleeve pullers and repops of the Ford special tool used to install them in the L-head, 134, and 172 CID engines. Quite literally hundreds sold and a waiting list for more.

Resleeving a small Kubota engine appears to be a more conventional machine shop operation. If quoting $800 for a two cylinder engine I would say that shop is not interested in the little piece work job. Probably too busy making way more money building performance engines.

Dan

Last edited:

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

Hmm, since the sleeve is 40 thou over....are there smaller pistons available ?

Maybe some othe rpistion for another engine would fit ,so no machining needed ??

just curious...

Maybe some othe rpistion for another engine would fit ,so no machining needed ??

just curious...

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

Yes. You try to hand hone .040 out and the hole is going to wander. If you are lucky it may be round and straight but it wont be plumb and square,My question is still out there . Is 0.040 too much to cut with a hone ?

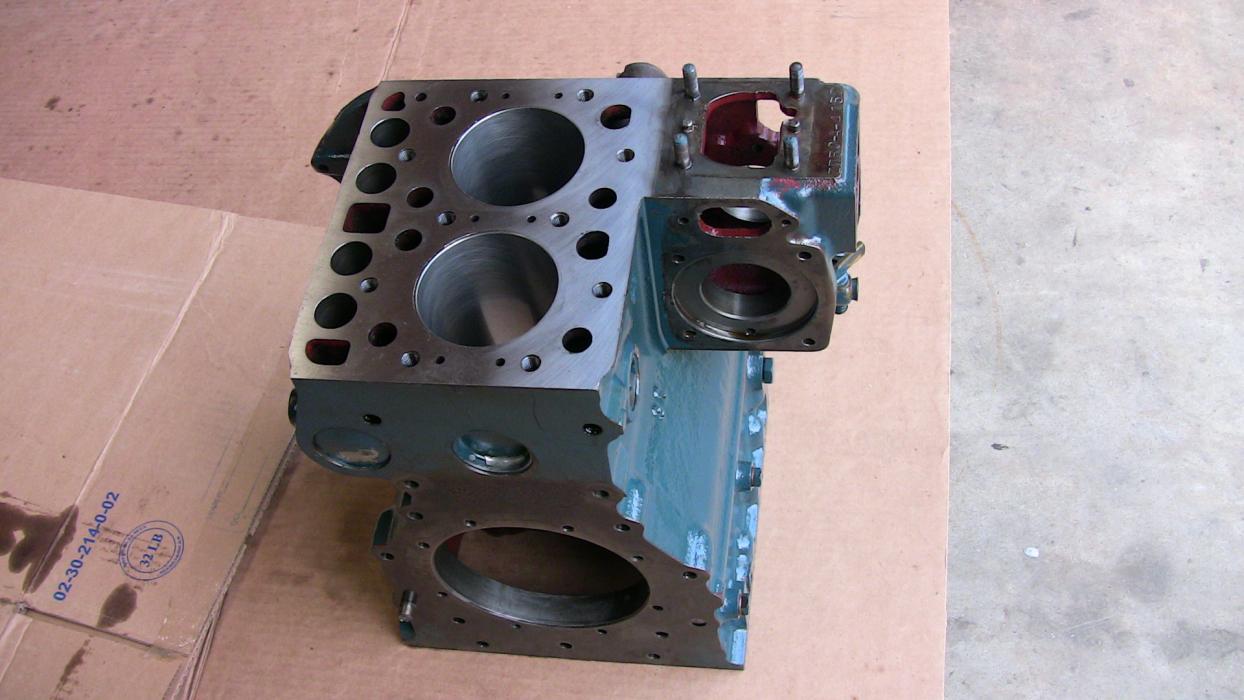

Here is a picture from an old thread. Same engine and old prices but he paid $180 to bore, hone and deck the block. This job does not require fancy engine boring equipment. It can be done with an old school boring bar or any decent size vertical mill - even a good size Bridgeport although that would not be my first choice. Setup on a vertical mill is trivial - 20 minutes or so to clamp to table and indicate first cylinder in. Then 10 minutes per cylinder to rough cut .030. Another 10 minutes for a scant .010 finish cut.. All told about an hour. Then you hone for final fit and surface finish.

You have been given some pretty solid advice by multiple individuals but its your engine and your money.

Dan

Thanks for the info. I have to think this one over .Yes. You try to hand hone .040 out and the hole is going to wander. If you are lucky it may be round and straight but it wont be plumb and square,

Here is a picture from an old thread. Same engine and old prices but he paid $180 to bore, hone and deck the block. This job does not require fancy engine boring equipment. It can be done with an old school boring bar or any decent size vertical mill - even a good size Bridgeport although that would not be my first choice. Setup on a vertical mill is trivial - 20 minutes or so to clamp to table and indicate first cylinder in. Then 10 minutes per cylinder to rough cut .030. Another 10 minutes for a scant .010 finish cut.. All told about an hour. Then you hone for final fit and surface finish.

You have been given some pretty solid advice by multiple individuals but its your engine and your money.

Dan