I’m not a highly-experienced “diesel” mechanic… got tons of professional experience on gassers…but not diesels..

One of the common methods to test piston-ring health in gasoline engines is to add some oil to the cylinder to help “seal” the rings to observe if there’s a significant “rise” in compression reading.

I’ve read on these forums similar advice given to use this technique on diesels. I’ve been informed anecdotally by experienced diesel techs that this can be very damaging due to the higher-compressions formed by smaller clearances within the piston-to-head interface of diesels. I.E.-if you put oil in a diesel and then crank the engine …you might bend a connecting rod or hole a piston.

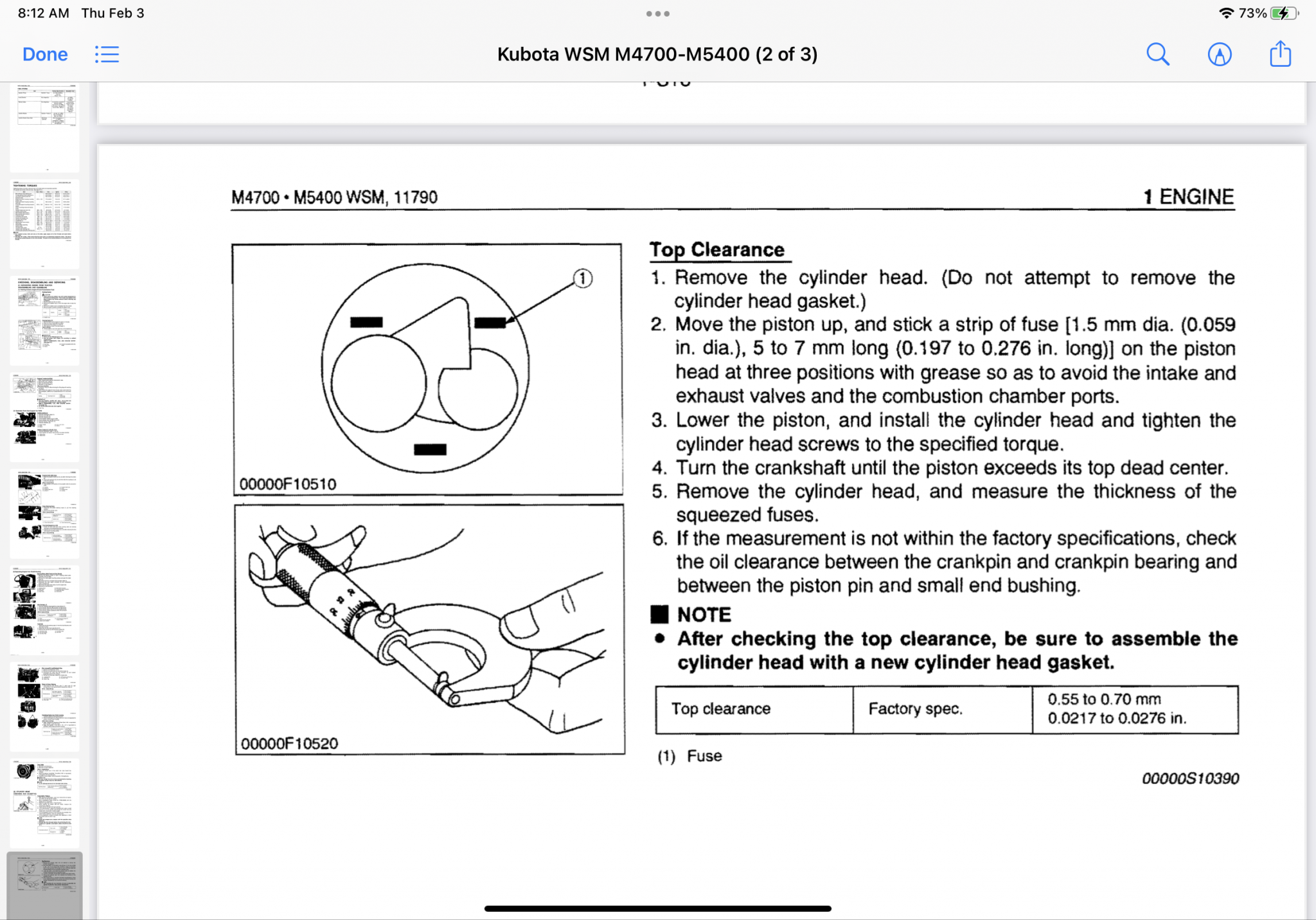

I was reading thru the WSM on my Kubota diesel (M4700) and it points out that when working on this engine …. when removing the head… DO NOT remove the old head-gasket. I found this curious until I read further… where they advise to place “fuse” material on the piston crown, reinstall the head, then rotate the piston beyond TDC …then remove the head AGAIN….to measure the “fuse” to see if it was compressed.

(after reading thru this, I realized that “fuse” refers to a product similar to “plastigage” products)

If the clearance between piston and head is adequate…then the instructions have you replace the head gasket with a NEW gasket during reassembly.

This educated me on two points:

1- The clearance between a piston and a head is LESS THAN .030” at TDC. …. So injecting oil into a cylinder to test for compressions would indeed be subjecting the engine to possible SERIOUS damage.

2- Leaving the old head gasket in-place for this test is intended to provide a ”used” / “compressed” gasket for the test…instead of a new gasket which might be somewhat thicker.

I hope this info is helpful to others. Here’s a screen-shot of the applicable page in the M4700 WSM (F-series engine)

One of the common methods to test piston-ring health in gasoline engines is to add some oil to the cylinder to help “seal” the rings to observe if there’s a significant “rise” in compression reading.

I’ve read on these forums similar advice given to use this technique on diesels. I’ve been informed anecdotally by experienced diesel techs that this can be very damaging due to the higher-compressions formed by smaller clearances within the piston-to-head interface of diesels. I.E.-if you put oil in a diesel and then crank the engine …you might bend a connecting rod or hole a piston.

I was reading thru the WSM on my Kubota diesel (M4700) and it points out that when working on this engine …. when removing the head… DO NOT remove the old head-gasket. I found this curious until I read further… where they advise to place “fuse” material on the piston crown, reinstall the head, then rotate the piston beyond TDC …then remove the head AGAIN….to measure the “fuse” to see if it was compressed.

(after reading thru this, I realized that “fuse” refers to a product similar to “plastigage” products)

If the clearance between piston and head is adequate…then the instructions have you replace the head gasket with a NEW gasket during reassembly.

This educated me on two points:

1- The clearance between a piston and a head is LESS THAN .030” at TDC. …. So injecting oil into a cylinder to test for compressions would indeed be subjecting the engine to possible SERIOUS damage.

2- Leaving the old head gasket in-place for this test is intended to provide a ”used” / “compressed” gasket for the test…instead of a new gasket which might be somewhat thicker.

I hope this info is helpful to others. Here’s a screen-shot of the applicable page in the M4700 WSM (F-series engine)

Last edited: