I've been snowblowing with a BX2822 on a BX2380 for several years, and Saturday I broke the fan shear bolt for the first time on what looked like clean fluffy snow. Replaced it today, twice now. Purchased the bolts from the dealer. As the snow piles up a bit in front of the fan between the augurs, I hear a clunking sound and the bolt breaks. If I back off quickly, the clunk will not recur and it won't break, and if I proceed very, very slowly it won't, either. It will run normally with no load. Visually, nothing looks wrong or bent and nothing feels loose. I have seen something similar reported elsewhere with a different blower, but no solution. The snow today is pretty heavy and wet, but not very deep, and it's not even close to the most extreme I have cleared before. Any suggestions?

BX2822 fan shear bolt breaks repeatedly under load

- Thread starter jsteinhauer

- Start date

You have to keep ice out of the unit . Even though I let my machine idle with the pto engaged for @ 5 minutes when I'm done blowing snow I still have to check to make sure nothing is frozen before I use it each time . This AM it was frozen when I went to use it . Quickest way to pop a shear pin is not checking to make sure it's free to run . I use a pipe wrench to make sure that teh augars will do a full rotation before starting & engaging the machine . The clunk clunk could be ice or something in the way of either of the augars . Make sure everything is clear before engaging PTO .

animals45

animals45

sigh, another need to be there to SEE and hear, what's happening...

it is a mystery...seasoned pro on known machinery, light fluffy snow... shouldn't be 'ice' problem....

mechanically everything is good... quiet,runs fine until you 'press' into the snow THEN clunk,clunk, break...

hmm... could there be something BETWEEN the fan and the housing ??

my train of thought...

OK, runs fine..just sitting there...NOT pushing /blowing snow

go forward into snow, that pushes the fan impeller back a bit

that presses onto the 'something'( stone/bolt/??) that gets 'wedged' against the back of the shell

that 'jamming' loads up the impeller and bang, shear bolt breaks

if you catch it at the right time(1st clunk..) you back up, releases the jammed 'object', release the pressure and the problem goes away.....

I know, it's not 'fun' to do ,but I'd remove the auger/fan assembly to confirm/deny a 'foreign object' IS behind the fan.

Haven't seen the drawing but there may be a 'locking bearing' on the drive end of the fan shaft. It not only supports the shaft it keeps it from moving back and forth. If it's NOT locked, pushing the auger/fan assembly in could cause binding and clunk,clunk.

sadly, it's a 'process of elimination'.....sure will be nice to read you FIND the reason, real soon !

it is a mystery...seasoned pro on known machinery, light fluffy snow... shouldn't be 'ice' problem....

mechanically everything is good... quiet,runs fine until you 'press' into the snow THEN clunk,clunk, break...

hmm... could there be something BETWEEN the fan and the housing ??

my train of thought...

OK, runs fine..just sitting there...NOT pushing /blowing snow

go forward into snow, that pushes the fan impeller back a bit

that presses onto the 'something'( stone/bolt/??) that gets 'wedged' against the back of the shell

that 'jamming' loads up the impeller and bang, shear bolt breaks

if you catch it at the right time(1st clunk..) you back up, releases the jammed 'object', release the pressure and the problem goes away.....

I know, it's not 'fun' to do ,but I'd remove the auger/fan assembly to confirm/deny a 'foreign object' IS behind the fan.

Haven't seen the drawing but there may be a 'locking bearing' on the drive end of the fan shaft. It not only supports the shaft it keeps it from moving back and forth. If it's NOT locked, pushing the auger/fan assembly in could cause binding and clunk,clunk.

sadly, it's a 'process of elimination'.....sure will be nice to read you FIND the reason, real soon !

I don't think there is anything stuck behind the fan. It turns freely when the bolt is sheared. I'm more afraid it's a problem in the gearbox. Something broken or worn in there might still catch without a load then slip under load causing the thunk. I might just take the blower off and use the front loader for the rest of the winter, praying we don't get a snowpocalypse before April, which is very possible here in northern Minnesota.

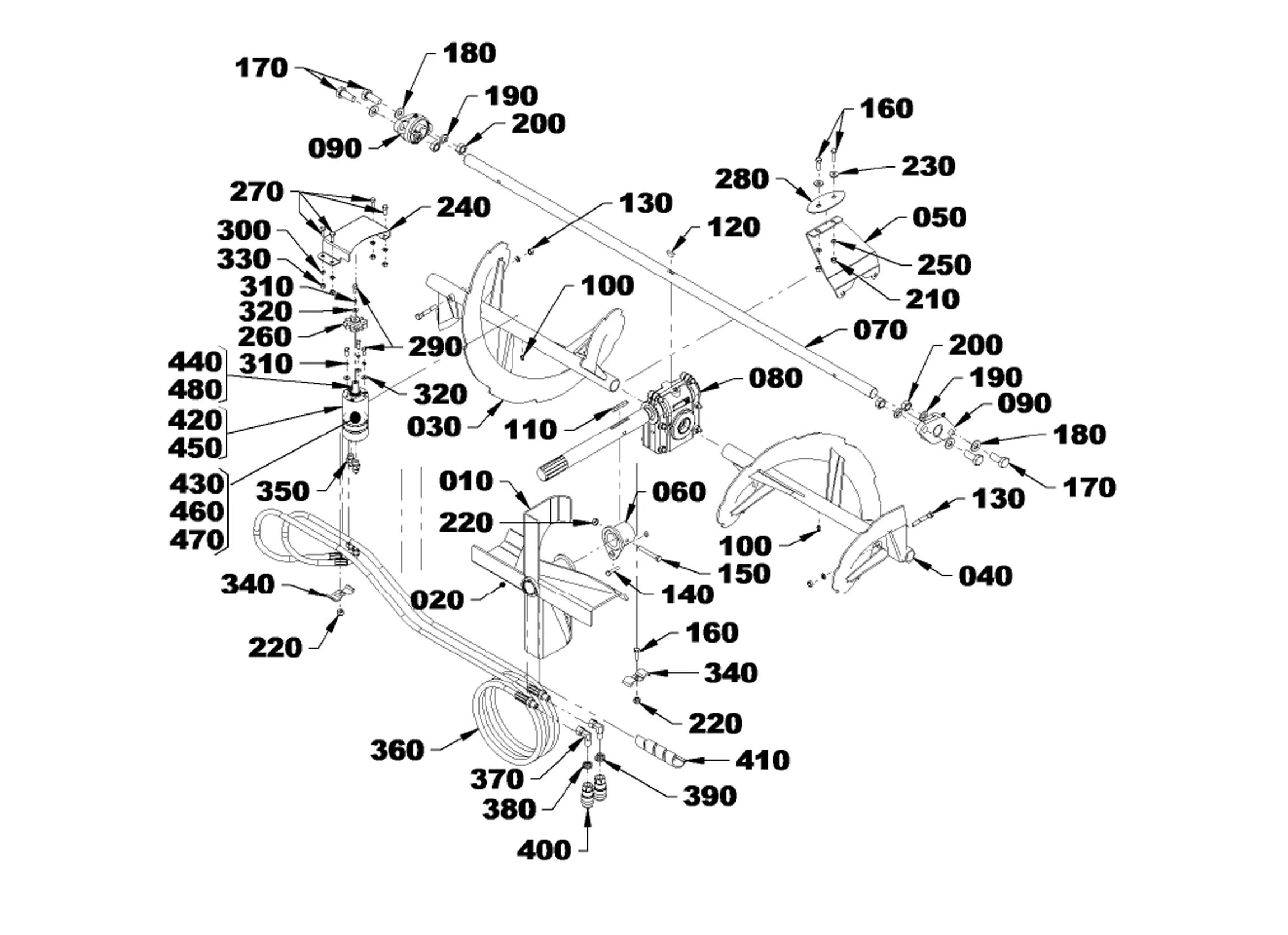

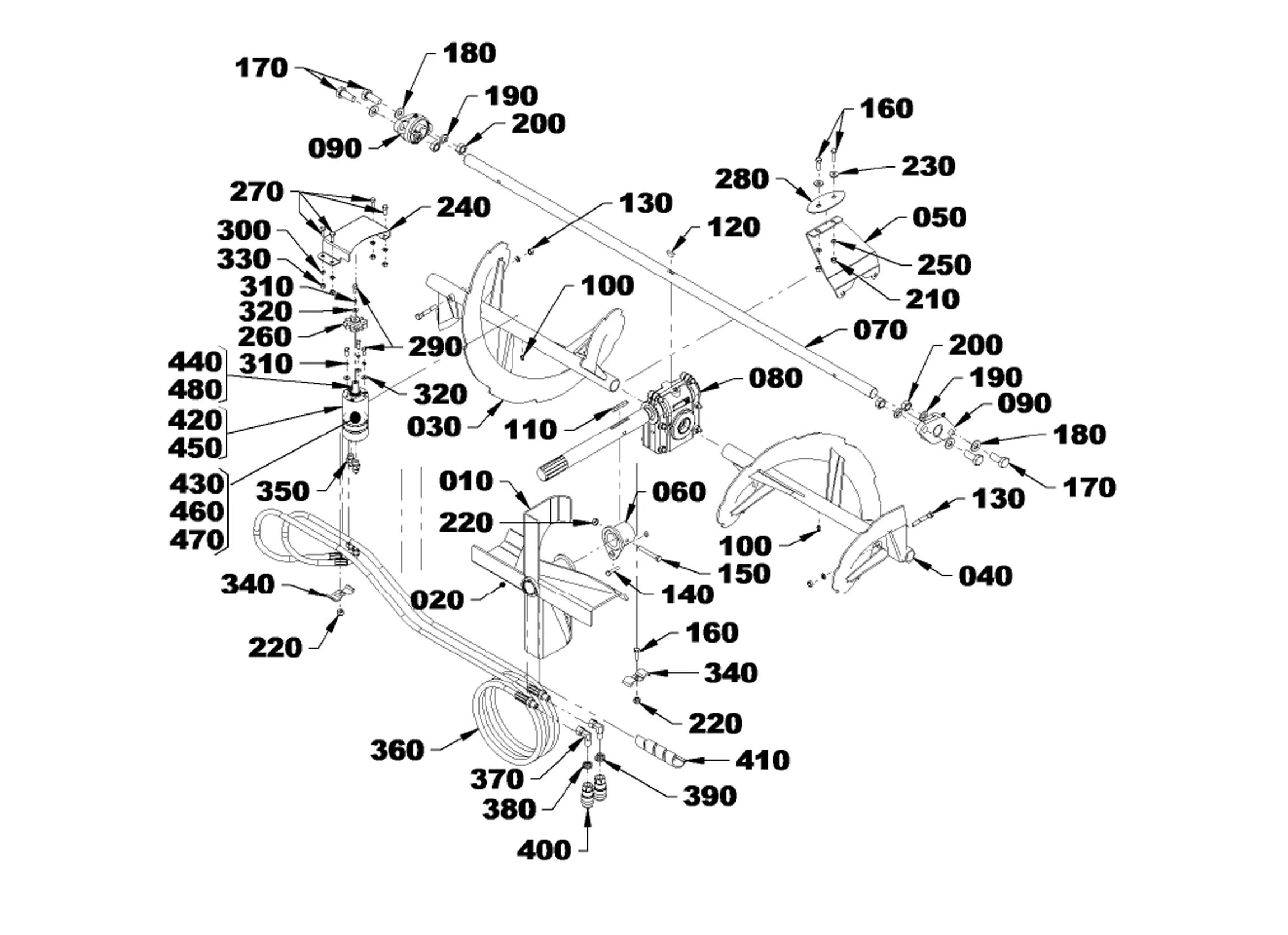

Heres a parts drawing , though not a very good one , I have been unable to find a drawing where your looking into the blower towards the fan

I have had equipment which had a broken part that was concealed & they way it was made it held the thing together . I've pulled apart several VW motors that made a horrendous noises but still ran that had a broken crankshaft but was heald together because the crank broke inside of a main bearing journal . Same thing with a Jaguar that had a cam that broke inside of the bearing journal .

I have had equipment which had a broken part that was concealed & they way it was made it held the thing together . I've pulled apart several VW motors that made a horrendous noises but still ran that had a broken crankshaft but was heald together because the crank broke inside of a main bearing journal . Same thing with a Jaguar that had a cam that broke inside of the bearing journal .

SO looking at the parts drawing this blower is hydraulic ?

with the blower raised & in whatever nuetral position the blower has & engine off can ou move the fan in either direction ? INteresting that the right side augar cost $70.00 more than the left augar .

animals45

Kubota BX2822A 55" COMMERCIAL FRONT SNOWBLOWER (BX2822A Snowblower) Parts Diagrams

Kubota Parts Catalog Lookup. Buy Kubota Parts Online & Save!

www.messicks.com

SO looking at the parts drawing this blower is hydraulic ?

with the blower raised & in whatever nuetral position the blower has & engine off can ou move the fan in either direction ? INteresting that the right side augar cost $70.00 more than the left augar .

animals45

I doubt it's the gearbox (dang simple in there...) the 'loading' shouldn't affect the gears spinning in it.

but...

once you remove it, get onto bench,drain oil, open it up... two gears.... check that each has all it's teeth.

you said it'll spin fine while NOT pushing snow....

I broke a tooth off the bull gear on my forklift. Once in awhile it'd get wedged between 2 teeth..DEAD STOP the forklift ! Maybe you have the same problem ??

it's the 'clunk, clunk...busted' ONLY when you push into the snow that's got me curious...

but...

once you remove it, get onto bench,drain oil, open it up... two gears.... check that each has all it's teeth.

you said it'll spin fine while NOT pushing snow....

I broke a tooth off the bull gear on my forklift. Once in awhile it'd get wedged between 2 teeth..DEAD STOP the forklift ! Maybe you have the same problem ??

it's the 'clunk, clunk...busted' ONLY when you push into the snow that's got me curious...

Have you made sure the augers are "alternating", not feeding at the same time? If both augers push snow into the fan at the same time, it may "overload" the fan. If there is any loose play on the fan, that hard push of snow may move something so there is some contact somewhere.

When changing shear bolts on augers, it is a common mistake to forget to check the orientation of the augers, to ensure they are 180 degrees offset at the center feed point.

When changing shear bolts on augers, it is a common mistake to forget to check the orientation of the augers, to ensure they are 180 degrees offset at the center feed point.

ken erickson

Well-known member

Equipment

B7100 hst, 2650 front mount snowblower, L2501 hst qa loader

I have no idea if it will help your situation but I was breaking fan shear bolts on my B2650 front mount blower. Turned out I was not tightening the shear bolt enough. I surmise that the fan was able to move independently from the shaft enough it put a lot more stress on the bolt when first engaging or moving into snow too fast. Since paying attention and getting the shear bolt and nut much tighter I do not think I have sheared one , going on 3 snow seasons now.

I had the augers misoriented for a time, well before this occurred. They are correct now. And I wish I had seen @ken erickson 's post earlier. I have the blower off the tractor and the loader back on. I don't know when I will get time to open up the gearbox, but I will be sure to post back, whether I find something or nothing. If it's the torque on the bolt, though, I won't likely know until next November or December.

My hands fit behind the fan. There is nothing back there. And the garage is heated. You can push the fan back about a centimeter when the bolt is sheared, it spins free as far back as it can go. It's fine for now. The loader is better for March snow most of the time, anyway.It could just be a hunk of ice or rock that managed to get behind the fan .

if you look down through the chute can you see behind the fan ? Can ou probe behind teh fan with a coat hanger or something like that ?

animal

I have a feeling that if you take the rear cover off where the chain is located, you will find that the shaft is moving ever so slightly and that the fan is contacting something that it shouldn't. It can also be worn bearings, and the replacements are so inexpensive that if you are going to take it apart, buying new bearings for your snowblower isn't going to break the bank. I have disassembled a bunch of chain drive snowblowers and given them a mini rebuild with new bearings and chain.

re: My hands fit behind the fan

really ??!!

I've never seen ANY snowblower with more than 1/2" gap between the 'disk' of the fan and the blower case. Ideally the gap should be 1/8- 1/4" inch to prevent anything from getting behind. The fan 'disc' should lineup with the rear of the chute,so all the snow goes into the chute and flung far,far away

really ??!!

I've never seen ANY snowblower with more than 1/2" gap between the 'disk' of the fan and the blower case. Ideally the gap should be 1/8- 1/4" inch to prevent anything from getting behind. The fan 'disc' should lineup with the rear of the chute,so all the snow goes into the chute and flung far,far away

Finally getting around to this project. The gear oil is pretty dark and full of fine powdery metallic flecks, but nothing larger than a speck of dust, at least what exits the drain. I find one Youtube disassembling a BX2755, which is similar schematically to this one, and in that example, the driving shaft backs out pretty effortlessly once all fasteners are removed. I've unbolted both bearings on the impeller shaft, and I've unbolted the gearbox from the gearbox support, so it should slide free, but it will not. I can't see anything in the diagrams that would be holding it in place. Any advice? Does the drive shaft need to be oriented specifically?

I notice the bearing behind the fan housing has a lock ring. The BX2755 bearing does not have a lock ring. Is this to lock the shaft in position, preventing it from being removed, without disassembling the rear of the blower?

I notice the bearing behind the fan housing has a lock ring. The BX2755 bearing does not have a lock ring. Is this to lock the shaft in position, preventing it from being removed, without disassembling the rear of the blower?

Last edited:

It's a "locking collar," and it fastens on to the drive shaft with a Allen setscrew. Once removed, the shaft backs easy out of the bearing. It's a little strange, because the collar was behind the rear flange, and the parts diagram shows it right up against the bearing with the flange behind the collar. I have not removed the flanges, yet. The bearing turns smoothly and quietly, so I doubt that it's shot. I might replace it anyway, since I've got it all apart, especially if I find nothing amiss in the gearbox. It's a $50 part. I did not find anything behind the fan, and there was only a little paint missing from the fan and the housing, which does not support something being lodged long enough to shear three pins. I probably won't work on it tomorrow.

Might be good to post of picture of it 'all apart' now, maybe others can see 'THAT" is what's wrong....?

hmm..this..

It's a little strange, because the collar was behind the rear flange, and the parts diagram shows it right up against the bearing with the flange behind the collar.

The locking bearing keeps the shaft from moving 'back and forth',fwds and bkwrds,in and out along with whatever is on the other end of the shaft so it should be 'snug' against the 'frame'.

Kinda humourous I'm NOT the only one working on SNOWBLOWERS in 90+ weather this week !!

hmm..this..

It's a little strange, because the collar was behind the rear flange, and the parts diagram shows it right up against the bearing with the flange behind the collar.

The locking bearing keeps the shaft from moving 'back and forth',fwds and bkwrds,in and out along with whatever is on the other end of the shaft so it should be 'snug' against the 'frame'.

Kinda humourous I'm NOT the only one working on SNOWBLOWERS in 90+ weather this week !!

There is nothing wrong inside the gearbox. I regret opening it, or even taking if off the shaft. Do you know what it is sealed with? Gray silicone-like material. I should have inspected the main shaft bearing first. Images are below. It turns freely, but it has two dents in the housing. I can't see how this could have occurred during operation, and I don't know that this was the cause of malfunction, but I will replace it, as well as the impeller shaft bearings, because I fouled one up during removal. I forgot that I had only loosened the set screws on the one side. I will need to sand down the shaft a bit, on the one side where I gouged it up with the bearing set screw. It's 50F today, here on the shore of Lake Superior. We see 90 degrees less than once a year here at the house. It's often 15-20 degrees warmer up on the county road.