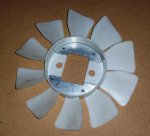

After finding out theat there were no fan blades left on my BX24, I researched the replacement of the $12.00, drive shaft mounted fan and found out these tractors (and possibly others) required disconnecting and then moving the engine forward to allow clearance to insert the fan. What a lot of work! My solution: make it a 2 piece fan! I cut two 1/16" thick pieces of aluminum that spanned most of the distance between the existing bolt holes, Matched the radius of the fan hub ID, but trimmed them to not interfere with the OEM mounting bolts. I clamped them to the fan and drilled two 1/8" holes through the fan and the aluminum on either side of what would be my saw cuts through the fan. I checked to make sure the 1/4" grip range POP rivets fit snugly and then cut the fan in two approximately 90 degrees from the OEM mounting holes. I installed the two fan halves and finger tightened the bolts. I installed the pieces of aluminum and inserted the pop rivets. After securing them I finished tightening the bolts (with a couple of drops of blue threadlocker). The fan runs true and works well. Then I made a split boot for the CV joint from a pie shaped piece of new inner tube! Pics are available

Attachments

-

94.7 KB Views: 1,997

-

96 KB Views: 1,603

-

93.8 KB Views: 2,479

-

89.4 KB Views: 2,764