Wow the deck is noisy, Just greased up and still the berings "rumble" is there a better set of berings that are a setp above "Stock"?

Thanks

Thanks

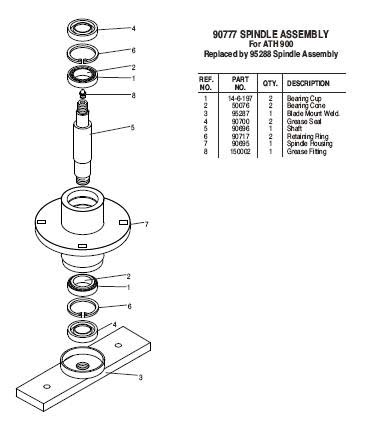

If you've never had a spindle apart, you can't imagine why a couple shots of grease do no good. There is enough room in there for half a tube of grease, and I'm talking the big one.

If I remember correctly you cannot over grease the spindles.If you've never had a spindle apart, you can't imagine why a couple shots of grease do no good. There is enough room in there for half a tube of grease, and I'm talking the big one.

Thank You for all the sugesstions! seems I have some work to do this weekend on the deck...

What is the "Shade tree mechanic" way of checking if the blades are balanced?