Mower and snowblower models in signature. I go through about 2 belts in a winter season. It's the belt between the clutch and quick attach pulley that keeps burning up. I can smell the belt burning within 2 minutes of use, even on a brand new belt. I originally was thinking the center pulley is dragging, but I don't see any grease points for the center pulley and it turns easily by hand without the belts attached. I've used kevlar and normal belts, both burn up. Thoughts on what to look for on why it could be going through belts so fast?

Burning through snowblower belts

- Thread starter orangekuby

- Start date

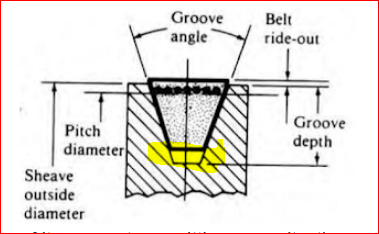

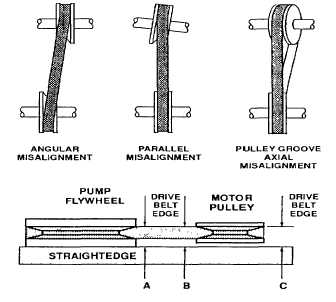

Have you looked at the runout, maybe the pulleys are out of alignment? How tight are the belts with the tensioner? I once rebuilt a set that was mismatched, the belt angle did not match one of the pulleys.

I did not think to check the pulley drag when hot, I will do that.

How would I fix the angle? I do remember the top side of the previous belt being extremely worn just before it broke, so maybe the pulley angle is off?

How would I fix the angle? I do remember the top side of the previous belt being extremely worn just before it broke, so maybe the pulley angle is off?

85Hokie

Moderator

Staff member

Lifetime Member

Equipment

BX-25D ,PTB. Under Armor, '90&'92-B7100HST's, '06 BX1850 FEL

See if the belt sits down IN the pulley ..... which it should NOT do if a standard V belt. Belts should ride on the edges of the pulley angled faces - not in the bottom of the groove itself.

Orange1forme

Active member

Equipment

B2650 HSDC, filled tires, wheel spacers, B2728B , LA534A FEL, 3rd valve kit

On another brand of belt driven sowblower, I had a similar issue that was solved by a second mounting position on the subframe.

Have you tried a straight edge across the pulleys and then check they are both the same internal angle for the belt groove angle as shown in 85 hokie's illustration.

I think it is a combination of alignment and belt face angle.

I think it is a combination of alignment and belt face angle.

Looks like I have some parallel misalignment according to asgard's picture. I'm not sure what I can do about this since the angle of the pulley is determined by the lever arms that move it up and down, and the lever arm position is determined by the rear pins on the raise/lower bars (that the mower deck uses too). Is there a way to correct this?

Picture is with the blower down as if I'm using it. In the up position it's slightly more aligned, but still not right.

Picture is with the blower down as if I'm using it. In the up position it's slightly more aligned, but still not right.

Attachments

-

265.1 KB Views: 496

85Hokie

Moderator

Staff member

Lifetime Member

Equipment

BX-25D ,PTB. Under Armor, '90&'92-B7100HST's, '06 BX1850 FEL

That right there will KILL a belt!!!!

Any kind of nick on that pulley and it will cook and tear a belt.

Any kind of nick on that pulley and it will cook and tear a belt.

Orange1forme

Active member

Equipment

B2650 HSDC, filled tires, wheel spacers, B2728B , LA534A FEL, 3rd valve kit

Looks like I have some parallel misalignment according to asgard's picture. I'm not sure what I can do about this since the angle of the pulley is determined by the lever arms that move it up and down, and the lever arm position is determined by the rear pins on the raise/lower bars (that the mower deck uses too). Is there a way to correct this?

Picture is with the blower down as if I'm using it. In the up position it's slightly more aligned, but still not right.

This seems to be the description I was given with my set up.

As I said, there was an additional set of holes in the rear of the sub frame, lower, that allowed the unit to drop. Once done, no more belt issues.

My only experience is with pulleys on wood working equipment, but I must say my first impression of belt alignment in your photo was pretty bad...

I think as others above with more experience with your equipment stated, you now know the answer to your question...

I think as others above with more experience with your equipment stated, you now know the answer to your question...

Do you have a picture of the holes you're referring to? I don't see another set of mounting holes that could change the geometry to align the belts. I'm wondering if I'm maybe missing some brackets or something.This seems to be the description I was given with my set up.

As I said, there was an additional set of holes in the rear of the sub frame, lower, that allowed the unit to drop. Once done, no more belt issues.

Look for and post a schematic of the pulley system. It's hard to offer any suggestions after seeing only one pulley.Looks like I have some parallel misalignment according to asgard's picture. I'm not sure what I can do about this since the angle of the pulley is determined by the lever arms that move it up and down, and the lever arm position is determined by the rear pins on the raise/lower bars (that the mower deck uses too). Is there a way to correct this?

Picture is with the blower down as if I'm using it. In the up position it's slightly more aligned, but still not right.

YIKES, even a blind man can see that's Waaaaaaaaaaaaaay wrong !!! My guess is that 'something' got bent and needs a good 'tweak' to realign things up. One of those 'gotta be there' repairs, to SEE what's wrong.

I'll have to take a look at it to see if any of the brackets or mounting points are bent. I know the plate arm things that connect the quick attack to the raise/lower arms of the mower are undamaged, but there may be others I haven't noticed.

Unfortunately I can't find any diagrams that show the whole snowblower/quick attack/tractor diagram. They're each individual and do not show the placement of each relative to the other.

Unfortunately I can't find any diagrams that show the whole snowblower/quick attack/tractor diagram. They're each individual and do not show the placement of each relative to the other.

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

The length of the arms is correct? If the pulleys were further apart the belt angle would be better.

Orange1forme

Active member

Equipment

B2650 HSDC, filled tires, wheel spacers, B2728B , LA534A FEL, 3rd valve kit

My situation, as stated, was with other mfr's equipment.Do you have a picture of the holes you're referring to? I don't see another set of mounting holes that could change the geometry to align the belts. I'm wondering if I'm maybe missing some brackets or something.

I was simply pointing out that belt alignment is crucial before looking anyplace else.

I had a riding mower(green) with a Bercomac snowblower. There was a subframe that had 2 sets of mounting holes and it came bolted in the upper holes and needed to be in the lower(or vice versa). once that was done, no more belt issues.

I cannot say what options you have.

Looking over all of the attachment points, I don't think there is anything to adjust. Only thing I can think of is something got damaged. The raise/lower arms can't move forward to correct the belt alignment due to the holes the pins go in, and the quick attach can't move back any farther because of the attachment point at the front. I don't see any pins or holes that can be changed either, so I may just have to take everything off and see what's not right.

Only thing I can think of is the belt from the blower to the quick attach is not the correct length and is putting unnecessary pull on the other belt, but I don't think that make sense since the raise/lower arms are fixed in position and wouldn't allow that.

If I ever find out what it was I'll share the solution, but for now I'll have to use it as is and have extra belts on hand.

Only thing I can think of is the belt from the blower to the quick attach is not the correct length and is putting unnecessary pull on the other belt, but I don't think that make sense since the raise/lower arms are fixed in position and wouldn't allow that.

If I ever find out what it was I'll share the solution, but for now I'll have to use it as is and have extra belts on hand.

Is it possible that somewere along the line the wrong length belt got put onto the machine? Perhaps the pullies are being 'pulled' too close together causing them to tilt?

That's a possibility for the snowblower side. I haven't replaced that belt in the two years I've owned it. I might take that one off and measure it.