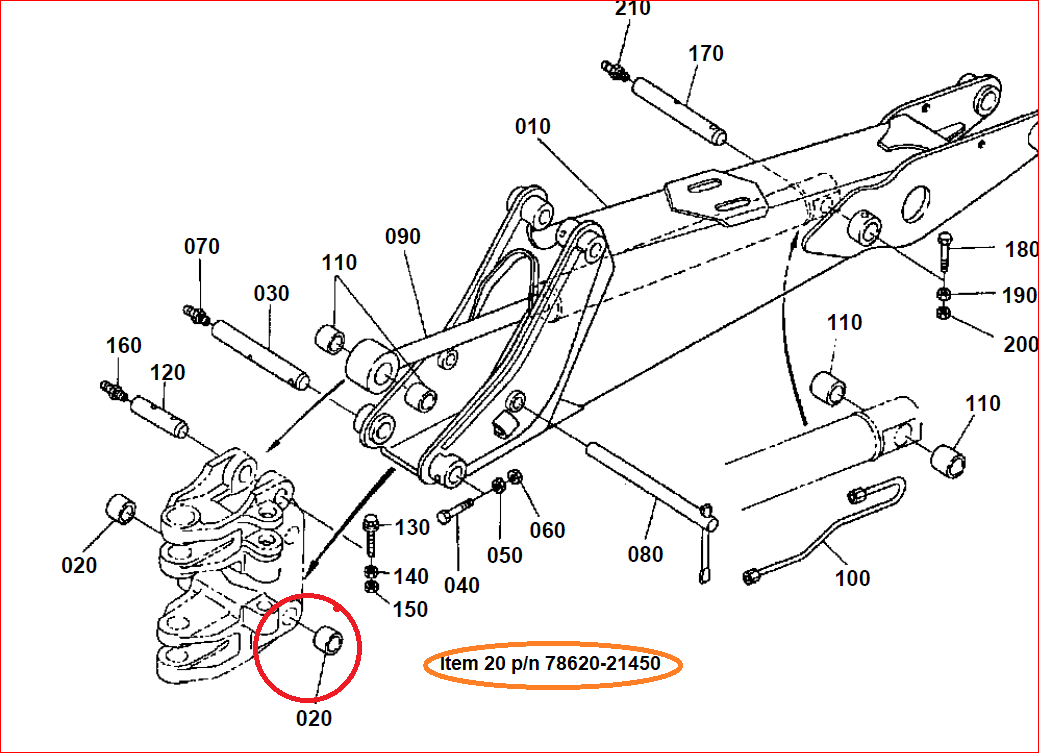

While taking things down to remove boom cylinder for reseal, took on replacing some bushings in that area as I felt there was "too much slop" as I moved the boom. Seemed like the pivot and such were a bit free.

I found two bushings, or "inner rings" on the swing frame where the boom pin goes though almost "fell out". They do not seem worn hardly at all, but do kind of "float" in their hole, when I would expect them to be a press fit. Like the difference between a "floating" piston pin and a press fit in a IC Engine.

Seems to me they could be free to rotate with the pin, inside the swing frame, where there is virtually zero lubrication is going to find it's way in, eventually causing a problem. As now discontinued part, at a cost of almost 3 grand, nothing to sneeze at, allergy season or not.

The WSM does not seem to go there as far as installation is concerned, so question is, should I try to fix those 2 rings in their bores, using some Lock tite sleeve mount or something, or am I being too cautious?

I found two bushings, or "inner rings" on the swing frame where the boom pin goes though almost "fell out". They do not seem worn hardly at all, but do kind of "float" in their hole, when I would expect them to be a press fit. Like the difference between a "floating" piston pin and a press fit in a IC Engine.

Seems to me they could be free to rotate with the pin, inside the swing frame, where there is virtually zero lubrication is going to find it's way in, eventually causing a problem. As now discontinued part, at a cost of almost 3 grand, nothing to sneeze at, allergy season or not.

The WSM does not seem to go there as far as installation is concerned, so question is, should I try to fix those 2 rings in their bores, using some Lock tite sleeve mount or something, or am I being too cautious?