Thanks for the input guys! The only reason why I'm a bit nervous of running it a higher speed is because my manual for the blower says not to exceed 540 rpm. It has a superior 200 gearbox and it states a higher rpm will blow the seals of the gearbox. To top it off, the previous owner put a nice thick coat of paint over the relief port on the gearbox. I'm going to order a new one so that if it does increase the pressure it has somewhere to blow off.

B7100 hydraulic question for the pros out there

- Thread starter OldeEnglish

- Start date

Well I got my parts in today but I hit a major bump in the road. Even though the chute sproket is 3/4 pitch the teeth are a bit too wide for the roller chain. I may file all the teeth  Or use my 10 T sprocket as a gear to turn the chute. Using it as a gear would work but I think it would wear the chute sprocket. I'm going to have to think about it. Filing every tooth on the chute will take a long time, maybe not too bad with a grinder... If I do that, they have to be perfect and there is no going back once that's done and it has to be perfect. Any thoughts?

Or use my 10 T sprocket as a gear to turn the chute. Using it as a gear would work but I think it would wear the chute sprocket. I'm going to have to think about it. Filing every tooth on the chute will take a long time, maybe not too bad with a grinder... If I do that, they have to be perfect and there is no going back once that's done and it has to be perfect. Any thoughts?

kubotasam

Well-known member

Equipment

B2410, B7100dt, B7500,Woods BH750,Landpride 2660RFM, Tiller, B2781 Snowblower

You don't need the chain to go onto the sprocket teeth of the blower chute. Have the chain around the motor sprocket then just wrap around the shoot. Set the chute direction pointing straight ahead then pin the chain in one place to the shoot with a small clamp of some sort. You only need 180 degrees of rotation. If the chute needed to spin 360 then you would need the chain to ride on the sprocket teeth. Depending on the speed of your motor you might need to incorporate some sort of a spring or other shock absorber device to keep the hydraulic motor from breaking something if it tries to go past 180. You might even be able to do a double wrap of the chain around the chute so you could get more than 180 degree rotation.

Another option put a small winch like drum on the end of the motor and use a cable instead of a chain.

Fasten the center of the cable to the drum. Do 3 or 4 turns around the drum on each side of the cable then run it out to the blower chute and make a couple of turns around with each end and clamp together and to edge of chute. This is how my rear blower rotates. I use an ATV winch instead of a hydraulic motor.

Another option put a small winch like drum on the end of the motor and use a cable instead of a chain.

Fasten the center of the cable to the drum. Do 3 or 4 turns around the drum on each side of the cable then run it out to the blower chute and make a couple of turns around with each end and clamp together and to edge of chute. This is how my rear blower rotates. I use an ATV winch instead of a hydraulic motor.

That's a great idea with the chain, I never thought of that, thanks for input. I've decided to use the sprocket as a gear, it should work out just fine. I have a gear reducer mounted to the motor so my math says the drive gear should spin at .33 RPS. That will rotate the chute 180 deg in 9 seconds and there is nothing fixed to the chute that could break.

I have to order a flange bearing, mount it within the space I created between the gear box and chute mount, to fix the drive shaft vertically. The gear box is a through shaft design and the supplier didn't have a schematic for the gear box when I ordered it. I thought of using 2 shaft collars and sandwich the gear box with them because every flange bearing I looked up didn't match the bolt pattern on the gear box. Im going to remove it again and paint the entire blower black, I can't stand the green. Here is a few pics.

I have to order a flange bearing, mount it within the space I created between the gear box and chute mount, to fix the drive shaft vertically. The gear box is a through shaft design and the supplier didn't have a schematic for the gear box when I ordered it. I thought of using 2 shaft collars and sandwich the gear box with them because every flange bearing I looked up didn't match the bolt pattern on the gear box. Im going to remove it again and paint the entire blower black, I can't stand the green. Here is a few pics.

Is there anyone out there that has any knowledge of this gear reducer? As I said before I did not get a manual with it and honestly don't have any knowledge of them. It's a durst brand 10:1 and I have a stupid question. It came with 2 breathers that I'm assuming need to installed on the sides where there are 4 Allen key plugs. This reducer can be mounted in different positions. My assumption is that the breathers should be installed on the "highest point" according to how the gear box is installed. I tried to copy the image off of surplus supply but they would not let me so the link to it is below. If better pictures are needed I will be taking it all apart tomorrow to paint and I can snap a few. You can slightly see in the picture above the 2 Allen key plugs. One towards the top offset to the right, and the other is towards the bottom offset to the left. Both sides are a mirror image.

http://www.surpluscenter.com/Brands...-RH-GEAR-REDUCER-SAE-A-MOUNT-13-1478-10-R.axd

http://www.surpluscenter.com/Brands...-RH-GEAR-REDUCER-SAE-A-MOUNT-13-1478-10-R.axd

Last edited:

coachgeo

Well-known member

Equipment

L225 w/woods Few Mowers & Back Blade, D722 in Motorcycle (Triumph Tiger), LMTV

Quick search for Durst manual comes up with

http://www.durstdrives.com/pump-drives/docs/pumpmanual.pdf

Considering that is from Durst's own website I would suspect that if that manual does not cover what you need a call to Durst or deeper search of their website might get you what you need

http://www.durstdrives.com/pump-drives/docs/pumpmanual.pdf

Considering that is from Durst's own website I would suspect that if that manual does not cover what you need a call to Durst or deeper search of their website might get you what you need

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Your not really using the unit for what it's really meant for (it's a high speed high torque unit).

A single vent on the unit will be more than enough to do the job.

A single vent on the unit will be more than enough to do the job.

Thanks guys, I did find that manual but my gear box is not covered under that.... I did email durst hopefully they will get back to me today. Wolfman you make complete sense. This model takes grease for lube but I would assume it would need at least one breather. Being that is is a sealed unit, any type of heat would create expansion pressure and obviously it would need to release that pressure somehow or the seals would blow. Unless the seals were meant for high pressure but I have nothing to tell me anything about this unit. I just found it strange it came with 2 breathers and no service/installation manual. I would assume the breather would be at the highest point otherwise the grease or lube would leak out...... But at the same time, there are a few different Locations where the breather could go. Like I said its a stupid question but I really don't know much about gear drives, motors, or power transmissions. I'm just a pipe jockey.

Well I finally made some progress on this project today. I hit a big bump in the road while trying to find a way to support the drive shaft vertically. After scratching my head and thinking about it over a few beers I found a way. The bolt pattern in this gear reducer has a 2 7/8" square bolt pattern. The problem was that I could find a flanged bearing with 2 3/4" bolt pattern for a 1" shaft only not an 1.25" shaft that I needed. Then it dawned on me to bring the shaft to a machine shop and have them mill down one end to a 1" diameter. One day at a professional machine shop and $20 for the labor I had a solution. I had to drill the flange bearing out from a 2 3/4 to a 2 7/8 pattern, just enough meat to make it happen. Now all I have left to do is plumb the hydraulics in and this bad Larry should work. Here are some pictures, the blower looks new with a nice rustoleum black paint job!

The shaft I had machined

Top view of the sprocket being used as a gear. It should work well, I can not get it to skip at all and will grease it well with some graphite lube

Bottom view of the flange bearing, the gear box is a through shaft and this worked out well

The shaft I had machined

Top view of the sprocket being used as a gear. It should work well, I can not get it to skip at all and will grease it well with some graphite lube

Bottom view of the flange bearing, the gear box is a through shaft and this worked out well

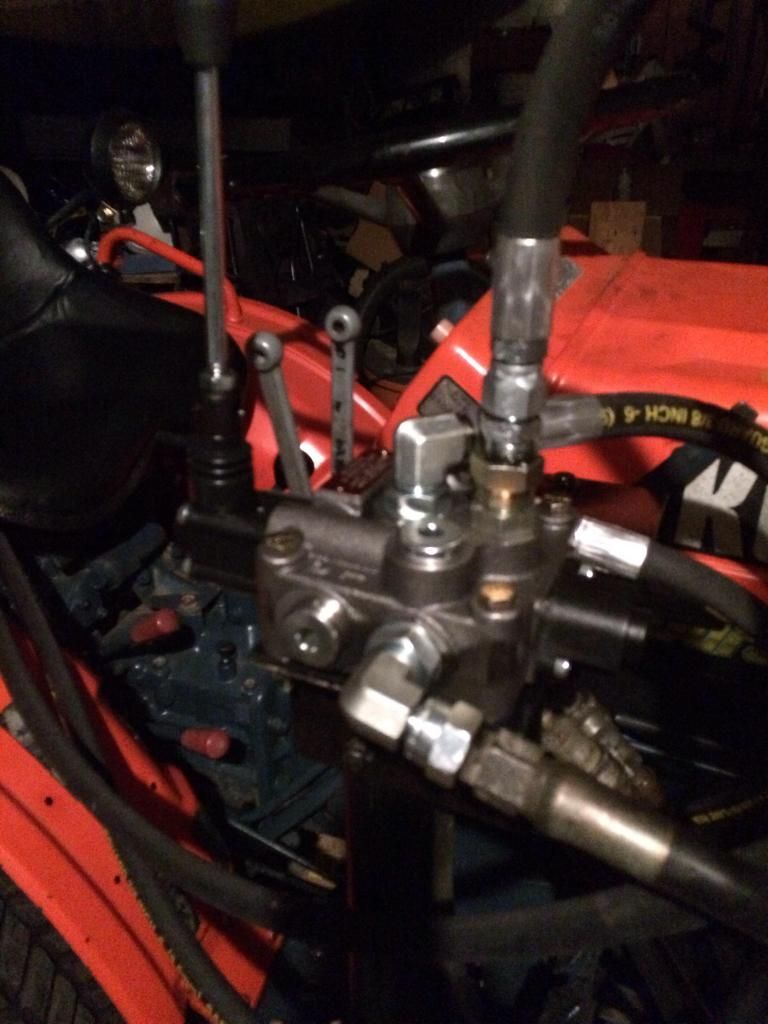

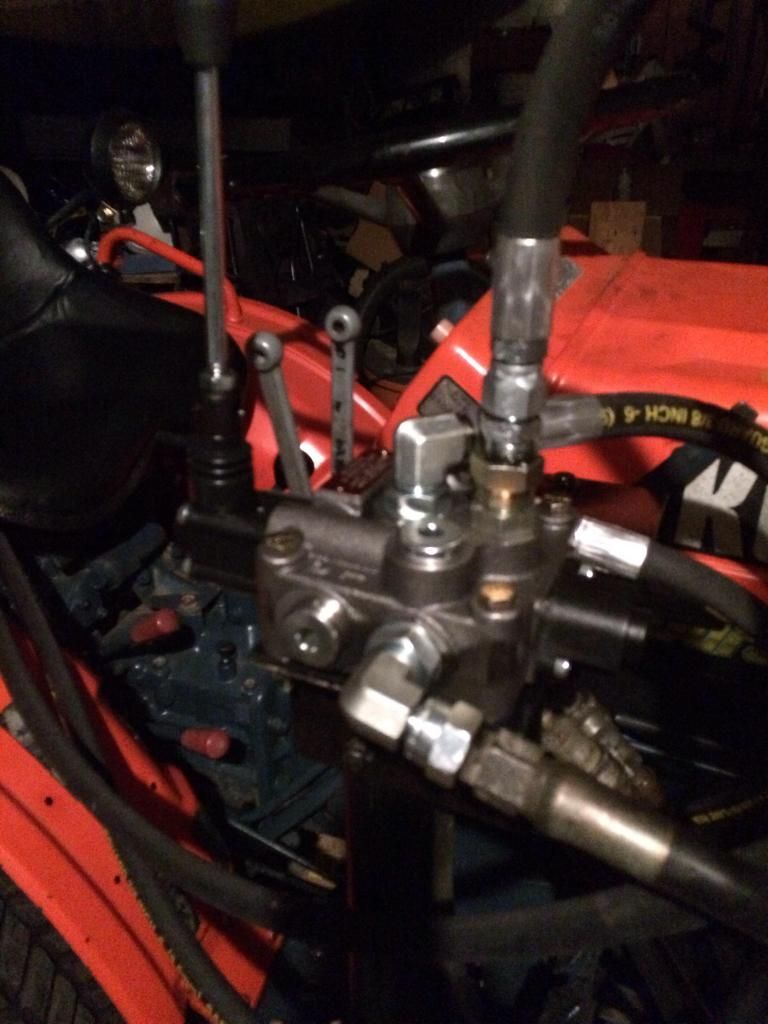

I was able to mount and plumb the spool valve in today, fired it up, and it works great!  The chute spun slower than my math calculated it to spin at....and I am very curious why....but I actually like it the way it is. All this time I was afraid it would move too quickly, at least this way I can put the snow exactly where I want it. I could speed it up by using a 12 or 14 tooth drive sprocket instead of a 10 but this works great for me.

The chute spun slower than my math calculated it to spin at....and I am very curious why....but I actually like it the way it is. All this time I was afraid it would move too quickly, at least this way I can put the snow exactly where I want it. I could speed it up by using a 12 or 14 tooth drive sprocket instead of a 10 but this works great for me.

I think building a chute rotator this way would work fine for any tractor that pumps more gpm than a b7100. I calculated 3gpm for a b7100, this could be where my math was off if 3gpm is not correct.

I want to list two things NOT to do if someone wants to do this. I always have to learn the hard way , not a huge deal but it cost me a few extra bucks.

, not a huge deal but it cost me a few extra bucks.

#1 - When buying a flange bearing, do NOT buy one that has a "lock collar." By looking at the picture on surplus supply it looks like the perfect setup, it is actually 2 pieced, and is honestly useless in my eyes unless you want to hang the weight of the shaft. Even then I don't see how this would benefit anything.... If anyone has a use for this please let me know, it's more or less a paperweight to me now.

#2 - When ordering hydraulic fittings.... The working ports on this prince valve are too close to spin 2 90's on of the same size. Order 1 regular 90 and 1 90 with a 2" extended length on the valve side. It was the last thing I needed to do and I was stuck, story of my life! I went to 3 car parts stores this afternoon with no luck, and finally lucked out at a plumbing supply company that happened to have a few fitting to make it work. I'll order the correct fitting later from surplus so that it looks like a clean job.

I don't know why there is an angry face at the header of this post but I am very happy with how this turned out!

I think building a chute rotator this way would work fine for any tractor that pumps more gpm than a b7100. I calculated 3gpm for a b7100, this could be where my math was off if 3gpm is not correct.

I want to list two things NOT to do if someone wants to do this. I always have to learn the hard way

#1 - When buying a flange bearing, do NOT buy one that has a "lock collar." By looking at the picture on surplus supply it looks like the perfect setup, it is actually 2 pieced, and is honestly useless in my eyes unless you want to hang the weight of the shaft. Even then I don't see how this would benefit anything.... If anyone has a use for this please let me know, it's more or less a paperweight to me now.

#2 - When ordering hydraulic fittings.... The working ports on this prince valve are too close to spin 2 90's on of the same size. Order 1 regular 90 and 1 90 with a 2" extended length on the valve side. It was the last thing I needed to do and I was stuck, story of my life! I went to 3 car parts stores this afternoon with no luck, and finally lucked out at a plumbing supply company that happened to have a few fitting to make it work. I'll order the correct fitting later from surplus so that it looks like a clean job.

I don't know why there is an angry face at the header of this post but I am very happy with how this turned out!

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

flynavy

Member

Lifetime Member

Equipment

B7100 HST-D w/FEL,654 Whel Hrs w/blade, 2654 Hsqv mowr, 28h Cfstm snowblower&cab

Currently I have a 2 spool return to center valve on my (1983/84) B7100 HST-D. One for the bucket tilt and one for the FEL lift. I'm adding a front snow blower to the 7100 and I'd like to change the valve to a 3 spool (3rd for lifting the blower) just so I don't have to be messing with quick connects and changing hoses accordingly. Snow blower already has a 12v chute motor. The cylinder for the snow blower has 2 lines one up one down.

Old English, thanks for the really nice clear photos, not to mention a great mounting job!

My problem is I need to know the GPM and PSI of the hydraulic system....anybody familiar. Because when I went to Tractor Supply they suggested I find out this info.....

Old English, thanks for the really nice clear photos, not to mention a great mounting job!

My problem is I need to know the GPM and PSI of the hydraulic system....anybody familiar. Because when I went to Tractor Supply they suggested I find out this info.....

Last edited:

Thank you for the kind words, mounting was really simple.... Just a few pieces of angle iron for the rotator and one piece of 2x2 angle trimmed to 1" on one side for the spool. Mounted it with 2 heavy duty tek 5 screws instead of welding. Plenty strong enough for what it needs to do.Currently I have a 2 spool return to center valve on my (1983/84) B7100 HST-D. One for the bucket tilt and one for the FEL lift. I'm adding a front snow blower to the 7100 and I'd like to change the valve to a 3 spool (3rd for lifting the blower) just so I don't have to be messing with quick connects and changing hoses accordingly. Snow blower already has a 12v chute motor. The cylinder for the snow blower has 2 lines one up one down.

Old English, thanks for the really nice clear photos, not to mention a great mounting job!

My problem is I need to know the GPM and PSI of the hydraulic system....anybody familiar. Because when I went to Tractor Supply they suggested I find out this info.....

I'm having trouble figuring out why you need an extra spool

If it was me.... I would probably spend the extra cash and change the double spool out to a loader spool. It would make using that FEL a lot easier., wish I had one for my plow. Then maybe tie that double spool in to add extra working ports for possibly making the 3 pt hits adjustable with a few hydraulic cylinders, top link, etc...

Tractor data states 3gpm for the 7100, I'm not sure of the exact pressure of the system. I actually need to test the pressure on mine at some point but have not gotten around to it. I would think anything open center could be used as long as the hydraulic pressure the tractor puts out doesn't exceed the max rated psi for the spool valves. I would think the 7100 is on the lower pressure side compared to other models.... But I could be wrong, someone like Wolfman or other pros could better answer that question.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

5 to 6 GPM (New valve will be way more and that's fine).

And Normal PSI of that system is 1800 to 2100 psi (and again new valve will probably handle way higher pressure)

And Normal PSI of that system is 1800 to 2100 psi (and again new valve will probably handle way higher pressure)

flynavy

Member

Lifetime Member

Equipment

B7100 HST-D w/FEL,654 Whel Hrs w/blade, 2654 Hsqv mowr, 28h Cfstm snowblower&cab

Thanks OE, Yes. this way I'll be able to drop the blower if necessary, and still have the bucket to do any scrapping. I considered quick connects but as i said don't want to mess with jockeying hoses. I try not to work any harder then necessary...LOL, so this way I'll have the best of both worlds on the machine at once. it's only 3 pins that hold the blower on, and the PTO shaft just slides off and done.

Thanks NIWman, I can always count on your expert info...BTW that inline water jacket heater we talked about is working great in this cold weather. Your advise saved me money not buying a magnetic heater since you told me the pan was aluminum. I never thought to even check it, as usual you came thru again.

Thanks NIWman, I can always count on your expert info...BTW that inline water jacket heater we talked about is working great in this cold weather. Your advise saved me money not buying a magnetic heater since you told me the pan was aluminum. I never thought to even check it, as usual you came thru again.

I can only see mounting the two at the same time being a recipe for disaster....one wrong move or a blown hydraulic line will turn that blower into a piece of scrap iron.... It also seems like that would be way too much weight for the front of that machine, and honestly not a safe idea..... But that's just me!

Have you thought about using the front blower and throwing a blade on the back for cleaning up behind you? Just a thought.... What about a 3 point blower?

I would rather have a front blower, but I find that plowing up some piles and running the blower through them limits the time of turning myself around to watch where I'm going. Just a thought for you! Post some pictures of what you end up doing, maybe someone has a way to build a stop so the FEL can't fall into your blower.

Have you thought about using the front blower and throwing a blade on the back for cleaning up behind you? Just a thought.... What about a 3 point blower?

I would rather have a front blower, but I find that plowing up some piles and running the blower through them limits the time of turning myself around to watch where I'm going. Just a thought for you! Post some pictures of what you end up doing, maybe someone has a way to build a stop so the FEL can't fall into your blower.

flynavy

Member

Lifetime Member

Equipment

B7100 HST-D w/FEL,654 Whel Hrs w/blade, 2654 Hsqv mowr, 28h Cfstm snowblower&cab

Thanks for the info, and your comments are well founded. I'm already taking care of your last comment....by adding a solid bar (w/hinge pins) to the subframe of the tractor to act as a block for the FEL so It'll be impossible for it to descend. When not using the snowblower the bar will be folded back against the side out of the way. As for the weight, this summer I poured a concrete slab, unable to get the truck back into the area I used the Bota bucket, filled with concrete (probably 1/2 yard) made about 20 trips, and she handled the load just fine. This blower doesn't weigh any where near that much.

This B2650 snow blower is just a toy for me to keep myself busy. I figured at some point my Craftsman SB will be worn out.. then I'll be ready. LOL. Wifee thinks I already have toooo many toys. 4 tractors (1) Wheel Horse with blade, (2) Husqvarna w/54" deck, (3) Crafstman 28hp w/snow blower and soft cab, and now the B7100 HST.

A few years ago I had a 3pt blower and got rid of it because it caused a pain in-the-neck, which in turn caused a pain in-the-A. Never got use to constantly looking backward...THAT was dangerous!

This B2650 snow blower is just a toy for me to keep myself busy. I figured at some point my Craftsman SB will be worn out.. then I'll be ready. LOL. Wifee thinks I already have toooo many toys. 4 tractors (1) Wheel Horse with blade, (2) Husqvarna w/54" deck, (3) Crafstman 28hp w/snow blower and soft cab, and now the B7100 HST.

A few years ago I had a 3pt blower and got rid of it because it caused a pain in-the-neck, which in turn caused a pain in-the-A. Never got use to constantly looking backward...THAT was dangerous!

Last edited: