Hello all, I have a good question for the hydraulic pros out there. I recently purchased a 70's B7100D in great shape (will post pictures tomorrow). I still can't believe how great of shape it's still in. It came with a kubota MMM and a B205 Dozer blade. I purchased it mainly for snow removal because my yard is too small to use the tractor to cut grass. My wife owns a bunch of land that I'll use it one some day. I'm looking into buying a 3pt snowblower so this where my question is. I was wondering if the tractor has enough hydraulic power to add a hydraulic Shute/deflector. I would use both the plow and snowblower together, so I would like to add two more remotes to my control tower and run the hydro lines to the rear. Anyone ever do this? I've searched many times and have not found any threads, but I could be looking in the wrong area. I know most people use electric motors but in my experience with them on my ariens, ice kicks the crap out of them. I'm a man of many trades but not electricity. If it's possible, what should I buy for control valves? Or should I buy a new control set up with 4 levers? I will post pics tomorrow to show what I'm working with. I'll need some guidance with the hydraulic system and supply/return plumbing. It's probably not worth doing but it would be handy.

B7100 hydraulic question for the pros out there

- Thread starter OldeEnglish

- Start date

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Yes it can handle as many cylinders as you want to run, they are no load till you use them, and then only if they are large will they be slow.I was wondering if the tractor has enough hydraulic power to add a hydraulic Shute/deflector. I would use both the plow and snowblower together, so I would like to add two more remotes to my control tower and run the hydro lines to the rear. Anyone ever do this? I've searched many times and have not found any threads, but I could be looking in the wrong area. I know most people use electric motors but in my experience with them on my ariens, ice kicks the crap out of them. I'm a man of many trades but not electricity. If it's possible, what should I buy for control valves? Or should I buy a new control set up with 4 levers? I will post pics tomorrow to show what I'm working with. I'll need some guidance with the hydraulic system and supply/return plumbing. It's probably not worth doing but it would be handy.

I personally would mount a two lever spool valve just for the rear control, less confusing.

just make sure the valves you get are open center, no need to get anything fancy like valves with power beyond, as your system won't use it.

Valves on a B7100 are just in and out.

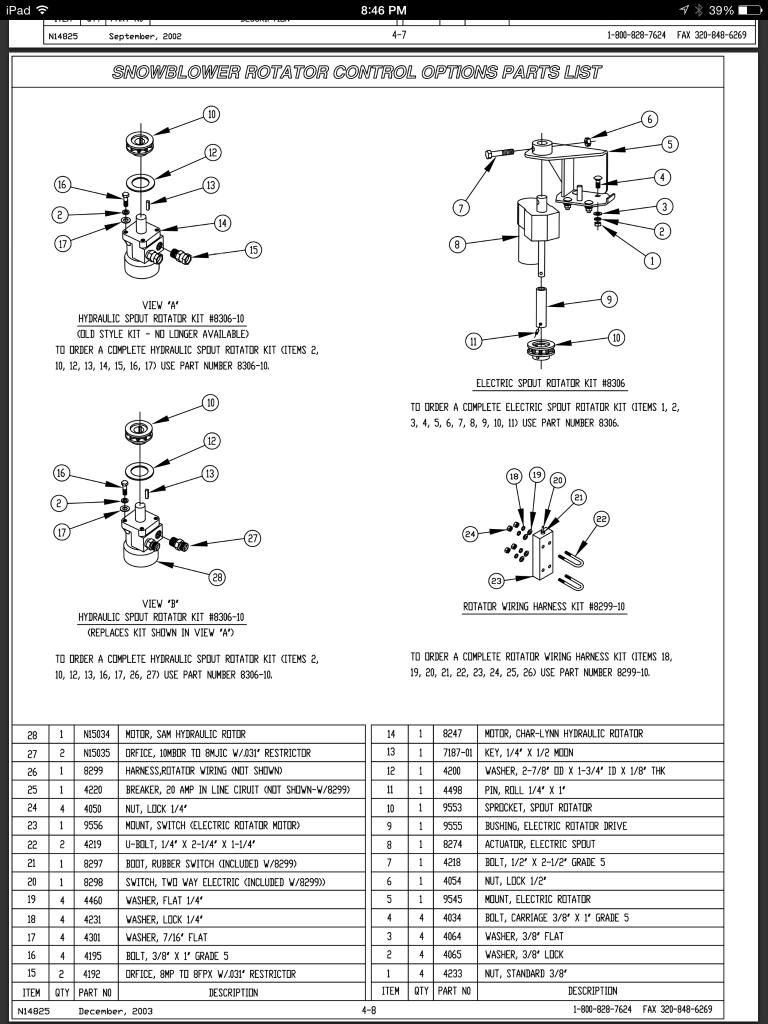

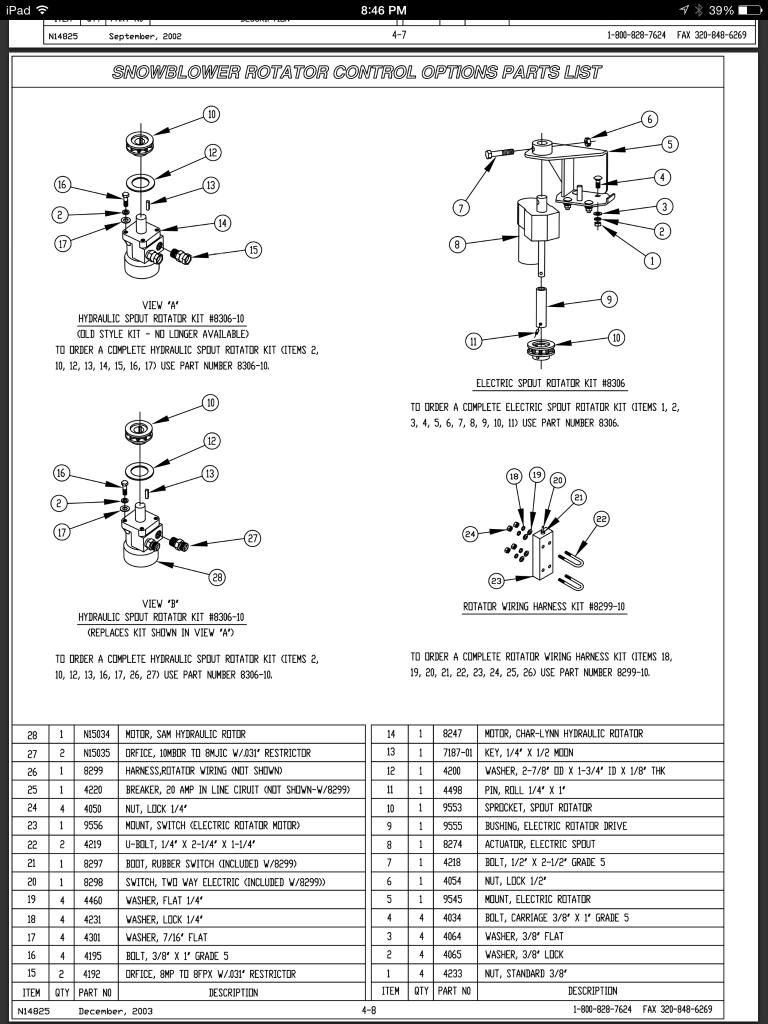

Today I decided to buy the hydraulic kits for my Loftness snowblower. Not a cheap option but unfortunately a must have. I only paid $900 for the blower, but the kits will run me $800 including 4 long hoses  . I'm searching for a open center two handle spool. I found a few around $150 that I have some questions about. Here are Two I found....

. I'm searching for a open center two handle spool. I found a few around $150 that I have some questions about. Here are Two I found....

Kubota double acting 2 spool open center. It says it returns to centered when pushed or pulled. 1/2" in and out 3/8 working ports. $130

Prince double acting 8gpm. SAE 8 ports. $151

Both found on eBay under open center hydraulic spool.

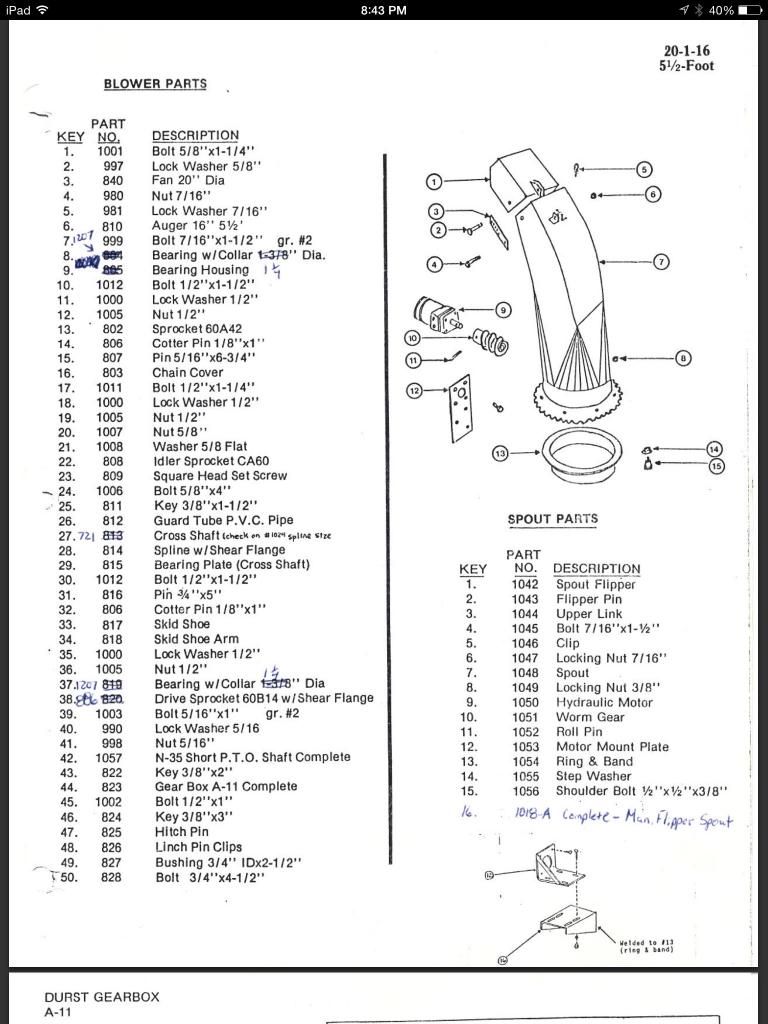

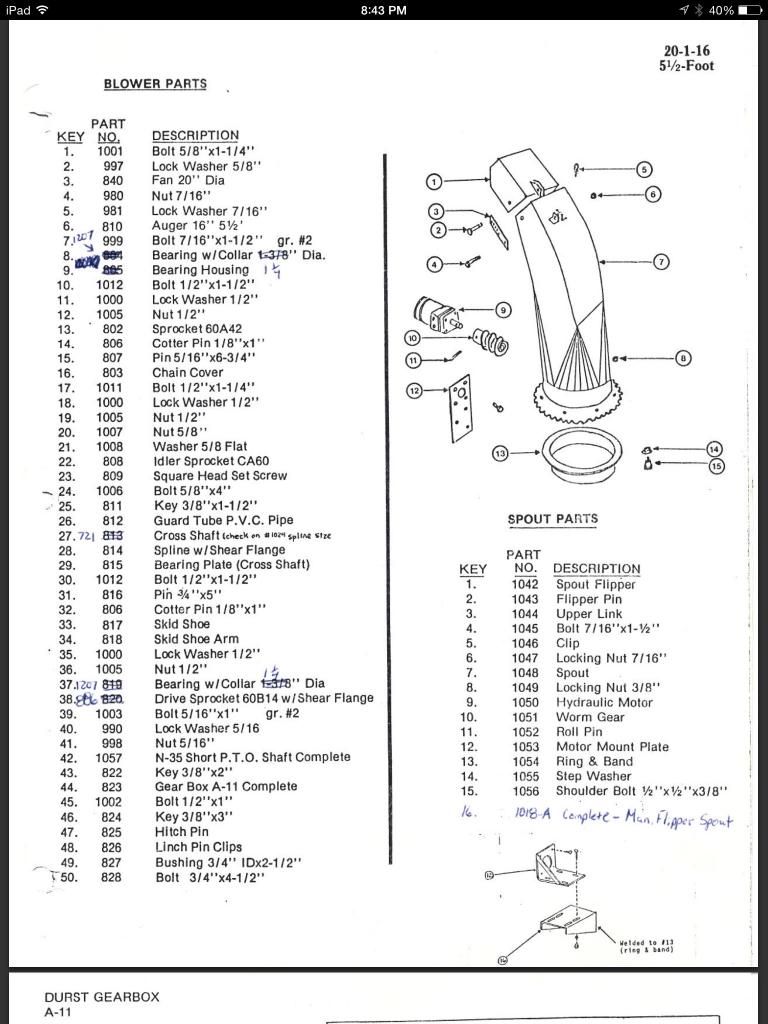

My question is, what is SAE 8? I'm unfamiliar with this type of thread sizing. I have little to no knowledge of hydraulic systems but I can pipe anything. Can I bush down the size from 1/2 to 3/8 if need be? I believe my tractor has 3/8 in and outs but I may be wrong. The hydraulic kits are all 3/8" size. Should I just go with the kubota valve? I'll attach the schematics of my hydraulic chute kits. Any help from any hydraulic pros would be appreciated. Let me know if I'm looking at the wrong type of valve, but I think I would need something on the low flow side with open centers as recommended by Idaho.

http://www.orangetractortalks.com/forums/album.php?albumid=351&pictureid=196

http://www.orangetractortalks.com/forums/album.php?albumid=351&pictureid=1960

http://www.orangetractortalks.com/forums/album.php?albumid=351&pictureid=1962

Kubota double acting 2 spool open center. It says it returns to centered when pushed or pulled. 1/2" in and out 3/8 working ports. $130

Prince double acting 8gpm. SAE 8 ports. $151

Both found on eBay under open center hydraulic spool.

My question is, what is SAE 8? I'm unfamiliar with this type of thread sizing. I have little to no knowledge of hydraulic systems but I can pipe anything. Can I bush down the size from 1/2 to 3/8 if need be? I believe my tractor has 3/8 in and outs but I may be wrong. The hydraulic kits are all 3/8" size. Should I just go with the kubota valve? I'll attach the schematics of my hydraulic chute kits. Any help from any hydraulic pros would be appreciated. Let me know if I'm looking at the wrong type of valve, but I think I would need something on the low flow side with open centers as recommended by Idaho.

http://www.orangetractortalks.com/forums/album.php?albumid=351&pictureid=196

http://www.orangetractortalks.com/forums/album.php?albumid=351&pictureid=1960

http://www.orangetractortalks.com/forums/album.php?albumid=351&pictureid=1962

Last edited:

I believe I'll try to match up my own kit for a chute deflector seeing that the kit from Loftness is $340. Is that a reasonable price for a cylinder and 2 long hoses?

I may be talking to myself here but I changed my mind. After a day of research I will go ahead and build my own setup. The most difficult piece to find is a worm or gear to turn my chute sprocket. I have two different possibilities to hook this up, but this is the way it should be...

This the only tractor on the web I found that has this exact system on the same blower. The worm looks to be 1" ID black pipe with splines welded on. Don't mind the color... It's for educational purposes only

The motor should not be a big deal as long as it's low in power and has the right size shaft to match the bore on the worm. I found my own answers to the questions I posted earlier. SAE is a straight style thread not tapered like NPT (this is all I ever use so please excuse my ignorance) and requires a o ring to seal. The spool is simple and straight forward as described by Wolfman.

So here is my new problem the worm. After drinking a 6 pack and educating myself on gear sizing, pitches, face, ect.... I need more beer.... Anyways the diameter of the blower chute sprocket is 14". There are 60 teeth on the radius. If my math is correct it puts me at about 4.25 pitch. Please anyone correct me if I am wrong because I am not a gear head. I searched and searched and found very little to match a 1" bore for a typical hydro motor. Loftness parts dealers seem to be a bit difficult to come by but I did send out some emails to a few of them hoping to find the factory worm.

Finding a gear to do a setup like the picture below is easy to find. I'm afraid if I do it this way the chute will turn too fast. Once again I am probably wrong because the 3GPM of my 7100 should not spin any motor that fast. Even so I would just need to add an Orphis and restrict the flow if that was a problem.

I'll update this thread once I know what parts are available from Loftness and at what cost. I refuse to pay more for a hydraulic setup than I did for the blower itself! Here is one more pic with the hand crank removed. If all else fails I'll adapt the motor to the hand crank but would rather not do that. As far as I can understand this thing, both hydraulic setups should work.

This the only tractor on the web I found that has this exact system on the same blower. The worm looks to be 1" ID black pipe with splines welded on. Don't mind the color... It's for educational purposes only

The motor should not be a big deal as long as it's low in power and has the right size shaft to match the bore on the worm. I found my own answers to the questions I posted earlier. SAE is a straight style thread not tapered like NPT (this is all I ever use so please excuse my ignorance) and requires a o ring to seal. The spool is simple and straight forward as described by Wolfman.

So here is my new problem the worm. After drinking a 6 pack and educating myself on gear sizing, pitches, face, ect.... I need more beer.... Anyways the diameter of the blower chute sprocket is 14". There are 60 teeth on the radius. If my math is correct it puts me at about 4.25 pitch. Please anyone correct me if I am wrong because I am not a gear head. I searched and searched and found very little to match a 1" bore for a typical hydro motor. Loftness parts dealers seem to be a bit difficult to come by but I did send out some emails to a few of them hoping to find the factory worm.

Finding a gear to do a setup like the picture below is easy to find. I'm afraid if I do it this way the chute will turn too fast. Once again I am probably wrong because the 3GPM of my 7100 should not spin any motor that fast. Even so I would just need to add an Orphis and restrict the flow if that was a problem.

I'll update this thread once I know what parts are available from Loftness and at what cost. I refuse to pay more for a hydraulic setup than I did for the blower itself! Here is one more pic with the hand crank removed. If all else fails I'll adapt the motor to the hand crank but would rather not do that. As far as I can understand this thing, both hydraulic setups should work.

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

That's great Wolfman feel free to post it on this thread. I've come up with my final design at it should work great for what I'm working with. The only thing to match up perfectly to the chute sprocket is #60 roller chain. 3/4 pitch by 1"bore sprockets are easy to find for $10. #60 chain is $20 for 10'.

It would basically work like a low gear in a 21 speed bicycle. With the motor mounted in the vertical position, slightly offset with a piece of flat steel for a mounting plate. As you can see in the picture above, the mounting holes are already slotted to allow adjustment for the chain. The hydraulic motor sprocket should easily level up with the chute sprocket with a few shims, or bend a slight offset in the mounting plate. I could even bend up a small chain guard out of sheet metal to finish it off.

Wolfman, what do you recommend for a motor size? The Loftness kit uses a 4 cu in motor. It shouldn't need a ton of power and the slower the better in my eyes. I'll order the parts this evening and will update during to build.

It would basically work like a low gear in a 21 speed bicycle. With the motor mounted in the vertical position, slightly offset with a piece of flat steel for a mounting plate. As you can see in the picture above, the mounting holes are already slotted to allow adjustment for the chain. The hydraulic motor sprocket should easily level up with the chute sprocket with a few shims, or bend a slight offset in the mounting plate. I could even bend up a small chain guard out of sheet metal to finish it off.

Wolfman, what do you recommend for a motor size? The Loftness kit uses a 4 cu in motor. It shouldn't need a ton of power and the slower the better in my eyes. I'll order the parts this evening and will update during to build.

Sae is a straight thread with a 45 degree tapered end. Jic is the common hydraulic with 37 degree tapered end. Sae is typically used on flare fittings for propane for instance.

The jic hydraulic ends are more readily available, they look the same, could be an oversight by the seller

Will need a flow restrictor to control the speed the chute moves.

The jic hydraulic ends are more readily available, they look the same, could be an oversight by the seller

Will need a flow restrictor to control the speed the chute moves.

Thanks for your input! It is sad winter is on the way. I try to make sure everything works before it hits 0 deg. There is nothing worse than working in the frigid temps with frozen fingers and a locked up spine!

No intent to hijack the thread, just have a similar question about Power Beyond and Open Center.

I'm told that Power beyond isn't all that fancy. That it is a better way to deal with daisy chaining valves where you might be inclined to use a diverter.

My current FEL/Backhoe uses a diverter and very old open center valves. I'm intending to replace the entire hydraulics runs with Power Beyond so I can ditch the diverter and use my FEL and Backhoe at the same time, which I need to raise the FEL sometimes to scoot the tractor along when I'm using the hoe.

So I've had to have the system redesigned to do just that and Power Beyond was the recommendation I got. Maybe I'm getting bad advice? Now this thread has me a bit confused again.

This was the Power Beyond system, complete with rear auxiliary and backhoe connections. Now I'm wondering if I just need to run it open center?

I'm told that Power beyond isn't all that fancy. That it is a better way to deal with daisy chaining valves where you might be inclined to use a diverter.

My current FEL/Backhoe uses a diverter and very old open center valves. I'm intending to replace the entire hydraulics runs with Power Beyond so I can ditch the diverter and use my FEL and Backhoe at the same time, which I need to raise the FEL sometimes to scoot the tractor along when I'm using the hoe.

So I've had to have the system redesigned to do just that and Power Beyond was the recommendation I got. Maybe I'm getting bad advice? Now this thread has me a bit confused again.

This was the Power Beyond system, complete with rear auxiliary and backhoe connections. Now I'm wondering if I just need to run it open center?

Attachments

-

97.9 KB Views: 363

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

To Tooljunkie's point,

SAE is still commonly used in hydraulics but more normally for the port connections on the valves. JIC is more common for hose connections. I've run into exceptions for both and it's quite maddening. I wish units had the standard they used put on plaque right on the vehicle/unit. It should be a legal requirement for any vehicle with hydraulics on it.

I tore apart a neighbors blue tractor hydraulics to find a mish-mash of standards, adapters, couplers and I felt like taking a rescue saw to the lot of it. Took me 2 weeks to get the issues straightened out on that beast and cost the owner almost an entire re-hose of the whole machine.

SAE is still commonly used in hydraulics but more normally for the port connections on the valves. JIC is more common for hose connections. I've run into exceptions for both and it's quite maddening. I wish units had the standard they used put on plaque right on the vehicle/unit. It should be a legal requirement for any vehicle with hydraulics on it.

I tore apart a neighbors blue tractor hydraulics to find a mish-mash of standards, adapters, couplers and I felt like taking a rescue saw to the lot of it. Took me 2 weeks to get the issues straightened out on that beast and cost the owner almost an entire re-hose of the whole machine.

Re: B7100 hydraulic question for the pros out there's

Fell free to post anything, I have many questions of my own. Hydraulic power is a science of its own. Simple but highly technical. Much like the mechanical trades, learning the terminology and the many types of fittings is half the battle. Honestly my experience with hydraulics is slim to none. Besides changing a few hoses or fixing a leak is far as I ever taken it. I ran a long run of 2" schedule 80 stainless steel thread pipe for a car wash hydraulic system a long time ago lol. Rebuilt a lift cylinder for the first time, but they are basically the same as rebuilding a back flow preventer minus the springs. So with that said I would love to read anyone's advice if they know what their doing.

I'll look into a flow restrictor for my unfit. I was curious wether the flow was adjustable through the spool? I haven't placed an order yet. I'm hung up between a $75 motor or a $160 one. The more expensive motor runs 750 rpm, almost half the speed of the cheapo. Anyone have an idea on which I should buy? Also this is the spool I was looking to buy. I was also thinking of a 2 spool loader valve instead of the valve that is described below. It would be more user friendly with chute rotation side to side and flapper with up and down. The last thing I want to do is accidentally spin the chute 360 deg and rip off the hydraulics! The valve described below is $150 and loader valve is much more expensive.

COMPACT 2 SPOOL DOUBLE ACTING DIRECTIONAL CONTROL VALVE

Brand new WOLVERINE by PRINCE MB series directional control valve for operating double acting cylinders. Ideal for small tractor and other low flow applications requiring a compact control valve. Features include monoblock construction, load check, built-in adjustable pressure relief valve, spring centering spool action, open center with enclosed plug to convert to power beyond or closed center, side or top inlet/outlet ports and vertical or horizontal handle mounting.

SPECIFICATIONS

Open Center Convertible to power beyond

or closed center

Spools Two

Flow 8 GPM max.

Pressure 3500 PSI max.

Relief Valve 2000 PSI, adj. 2000-3500 PSI

Reqd. Filtration ISO 4406 19/17/14

In/Out Ports SAE 8

Work Ports SAE 8

Mount 3 hole base

Size 7-5/8" x 5-7/16" x 2-1/4"

Spool Details:

Spool 1 DA cylinder spool, spring to center

Spool 2 DA cylinder spool, spring to center

Fell free to post anything, I have many questions of my own. Hydraulic power is a science of its own. Simple but highly technical. Much like the mechanical trades, learning the terminology and the many types of fittings is half the battle. Honestly my experience with hydraulics is slim to none. Besides changing a few hoses or fixing a leak is far as I ever taken it. I ran a long run of 2" schedule 80 stainless steel thread pipe for a car wash hydraulic system a long time ago lol. Rebuilt a lift cylinder for the first time, but they are basically the same as rebuilding a back flow preventer minus the springs. So with that said I would love to read anyone's advice if they know what their doing.

I'll look into a flow restrictor for my unfit. I was curious wether the flow was adjustable through the spool? I haven't placed an order yet. I'm hung up between a $75 motor or a $160 one. The more expensive motor runs 750 rpm, almost half the speed of the cheapo. Anyone have an idea on which I should buy? Also this is the spool I was looking to buy. I was also thinking of a 2 spool loader valve instead of the valve that is described below. It would be more user friendly with chute rotation side to side and flapper with up and down. The last thing I want to do is accidentally spin the chute 360 deg and rip off the hydraulics! The valve described below is $150 and loader valve is much more expensive.

COMPACT 2 SPOOL DOUBLE ACTING DIRECTIONAL CONTROL VALVE

Brand new WOLVERINE by PRINCE MB series directional control valve for operating double acting cylinders. Ideal for small tractor and other low flow applications requiring a compact control valve. Features include monoblock construction, load check, built-in adjustable pressure relief valve, spring centering spool action, open center with enclosed plug to convert to power beyond or closed center, side or top inlet/outlet ports and vertical or horizontal handle mounting.

SPECIFICATIONS

Open Center Convertible to power beyond

or closed center

Spools Two

Flow 8 GPM max.

Pressure 3500 PSI max.

Relief Valve 2000 PSI, adj. 2000-3500 PSI

Reqd. Filtration ISO 4406 19/17/14

In/Out Ports SAE 8

Work Ports SAE 8

Mount 3 hole base

Size 7-5/8" x 5-7/16" x 2-1/4"

Spool Details:

Spool 1 DA cylinder spool, spring to center

Spool 2 DA cylinder spool, spring to center

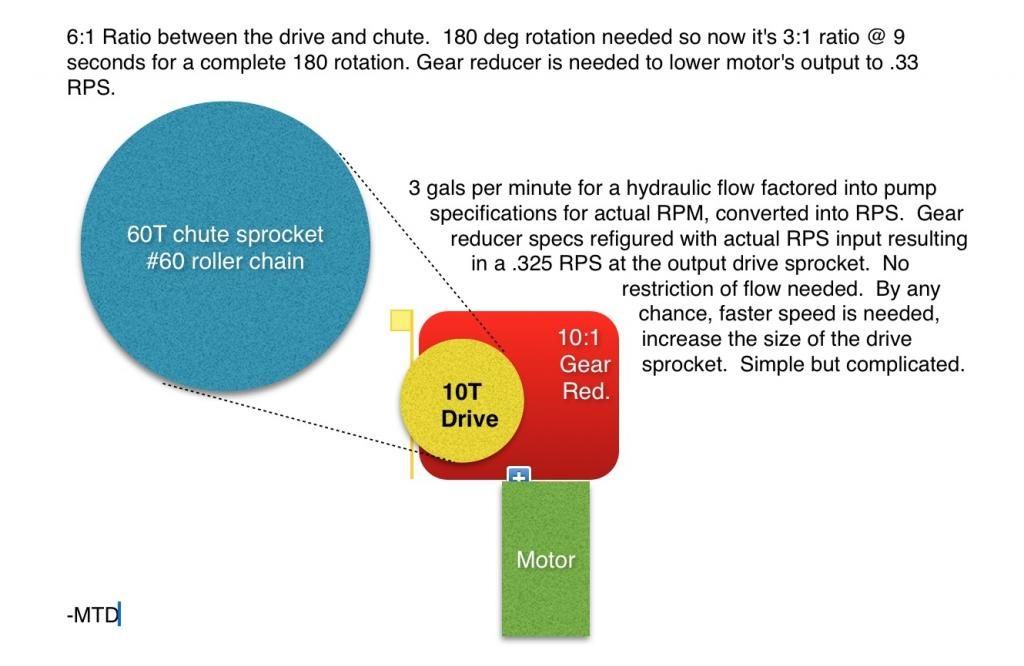

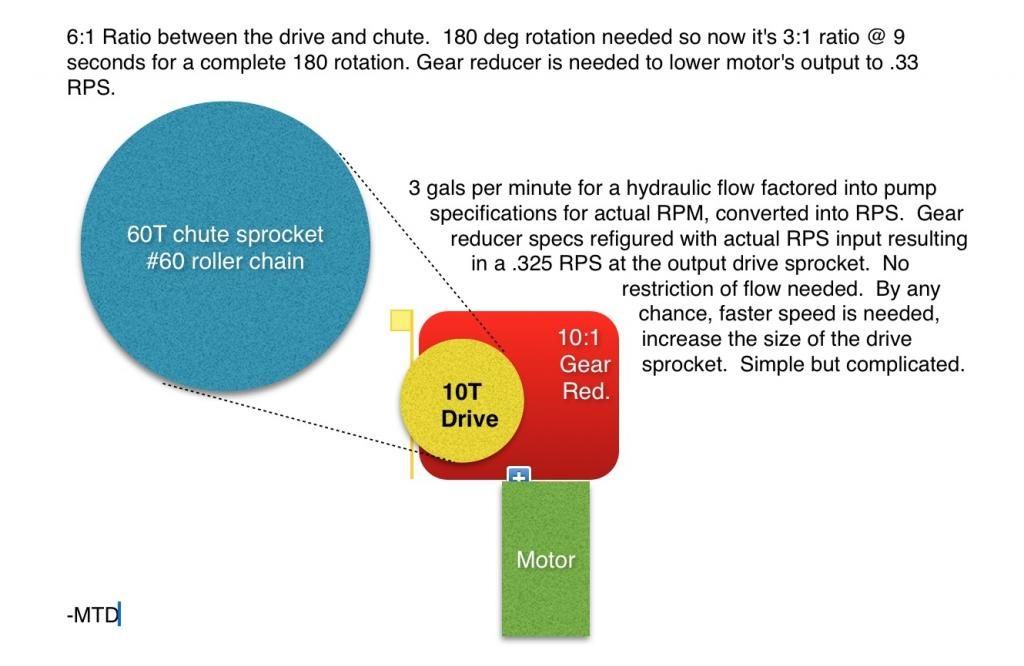

So here is my final design to install this hurdaulic rotator. It sure has been a head scratcher and has taken me back to some math I haven't used in a long time. All of the parts needed including spool, hoses, motors, ect. Comes to $550 shipped to my door. A good $200 savings over buying through Loftness.

No restriction of flow needed what so ever. I feel 9 to 10 seconds is slow enough to rotate the Shute 180 deg. The hydraulic motor does not have a case drain, I hope that is a good thing. The pump is $150 but it is zinc plated! I'll post pics of the build in a week or so, should be an easy install.

[/URL]

[/URL]

No restriction of flow needed what so ever. I feel 9 to 10 seconds is slow enough to rotate the Shute 180 deg. The hydraulic motor does not have a case drain, I hope that is a good thing. The pump is $150 but it is zinc plated! I'll post pics of the build in a week or so, should be an easy install.

I just ordered all of the parts, holy sticker shock  . This b7100 better throw some snow! I'm a bit nervous that the tractor's PTO 514 rpm will effect the snowblower that is rated for 540. I know a lot of people out there use snowblowers on their b7100 but I'm still nervous. I'm in the whole setup for $5000 now including a bunch of new parts on little orange. As long as it can throw the snow at a good 10 ft radius I'll be happy. My driveway is a pain to plow because I don't have anywhere to push big piles, snowblowers work the best. Can anyone confirm how far their B7100 throws snow to make me feel better?

. This b7100 better throw some snow! I'm a bit nervous that the tractor's PTO 514 rpm will effect the snowblower that is rated for 540. I know a lot of people out there use snowblowers on their b7100 but I'm still nervous. I'm in the whole setup for $5000 now including a bunch of new parts on little orange. As long as it can throw the snow at a good 10 ft radius I'll be happy. My driveway is a pain to plow because I don't have anywhere to push big piles, snowblowers work the best. Can anyone confirm how far their B7100 throws snow to make me feel better?

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Simple fix run it at the 786RPM setting and idle the tractor down a little.

You should be able to get 20+ feet without a hitch!

I have been running my snowblower at the 1000RPM PTO setting on my L, and just lowering the speed of the motor, works like a charm!

I can throw snow 60+ feet with mine.

You should be able to get 20+ feet without a hitch!

I have been running my snowblower at the 1000RPM PTO setting on my L, and just lowering the speed of the motor, works like a charm!

I can throw snow 60+ feet with mine.

Well Wolfman I'll take your word for it and do as you suggested, thanks for the input. Quick question, with the b7100's throttle petal, are you supposed to run the tractor at full throttle for a long period of time or will that burn the engine up? My tractor seems to be missing the oil pressure light and I have no way of knowing if the tractor is over reving. She's an old girl but the engine purrs like a kitten.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

kubotasam

Well-known member

Equipment

B2410, B7100dt, B7500,Woods BH750,Landpride 2660RFM, Tiller, B2781 Snowblower

I always run the rear snow blower on the second pto speed on my B7100. The only time I need to drop to the 1st speed is when blowing back a packed snow bank. The tractor just does not have enough power to run the 2nd speed doing that. I can throw 40 feet easily with my setup. Hope my new front mount blower for the other tractor works as well.Simple fix run it at the 786RPM setting and idle the tractor down a little.

You should be able to get 20+ feet without a hitch!

I have been running my snowblower at the 1000RPM PTO setting on my L, and just lowering the speed of the motor, works like a charm!

I can throw snow 60+ feet with mine.