CURRENTLY SOLD OUT. Making more is a winter project. I will remove this line when I have made more.

These are obsolete and no longer available. I have recently been contacted by a member asking if I will make him one of these after reading how I made mine. I know this comes up from time to time and would like to gauge the interest others might have -- if I`m going to set up to make a couple, I may as well make a few more.

Here are some photos of what I made in the past. I made the two shown out of steel, as that is what I had on hand, but I`m thinking aluminium would function just as well, be resistant to corrosion and cheaper to ship. I`m not sure of pricing yet -- I know metal pricing has shot up over the last year -- but would estimate it to be in the $30 to $50 range. Plus shipping.

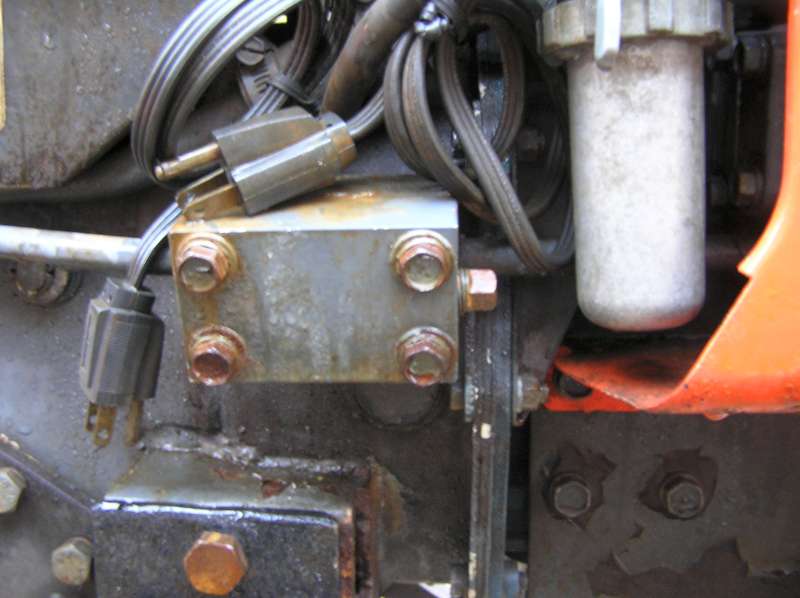

Stock cover:

Inside of stock cover:

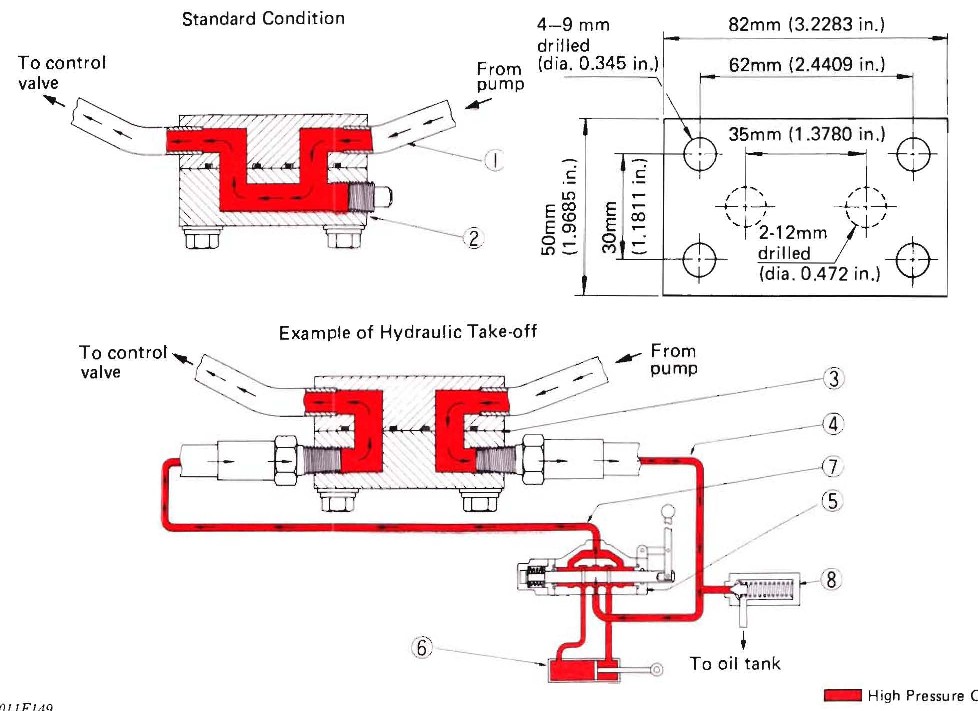

Inside (left) and outside (right) of diverter cover (note there is a third tapped outlet provided on the bottom face, all outlets tapped 3/ 8" NPT. Plug the unneded outlet or add a pressure gauge):

Hydraulic schematics from B7100 manual:

UPDATES:

Through the course of this thread, we found that these blocks will fit many other models, by adding a choice of ports, like so:

(The above pic shows a total of 6 ports, this was later refined to 4 ports.)

The "universal" block pictured should fit most of the older B and L series tractors:

B5100/6100/7100 (Note, the block was added to the design at some point during the production cycle. Really early models don't have this capability. Look on the right side, just rear of the engine behind the fuel filter. Does it have the block pictured in the first post of this thread? If so, then this cover will work on your machine.)

L185/235/245/275/285/295/305/345/355 (replaces 35300-36720)

L3350 (now confirmed)

(if you know of others, please let me know and I'll add them to the list).

The multitude of ports is only intended to ensure the block is compatible with a wide range of models and provide options for hose routing.

Use one port from the left side and one from the right. If you want, you could connect a pressure gauge to a third. Plug the others. It comes with plugs to block off the unneeded pair.

Warning:

These blocks intercept the flow of hydraulic oil between the pump and the 3ph. They MUST only be used in combination with an end-user supplied connection between the left and right halves, such as a properly plumbed FEL control valve, power steering control, etc. Failure to connect something between the ports will result in a rapid loss of hydraulic fluid. You can pick any two ports and plug the others but

installing plugs in ALL the open ports will result in rapid and potentially catastrophic failure of the hydraulic system.

At the very minimum, you must install a hydraulic hose between any port on the left and any port on the right halves before cranking the engine.

I would think this is self-evident, but I don't know the skill level of those that are planning to get one. If you are in doubt, as for help. If you ignore the above you will have my sympathy and a broken tractor.

Pricing:

Dan "theoldhokie" is not currently making them due to health issues.

The price is currently CDN$40 or US$30, plus actual shipping. PM me with your address for an actual shipping quote, but it's usually around $20 - $25 within North America (shipping within Canada is taxable, shipping internationally is not). I will also ship overseas, that seems to run CDN$35 to $50. Customs also requires a phone number on their paperwork. I accept Interac from Canadians or Paypal from others.

NOTE: this is very much an open hardware community driven project. If you want to make your own, the measurements are posted above. If you want to make them for others, you have my blessing. I claim no patent or copyright on the design.

CURRENTLY SOLD OUT. Making more is a winter project. I will remove this line when I have made more.

I would buy three of the blocks, maybe save on shipping,? aluminum is fine and easier to machine.

thanks Eric