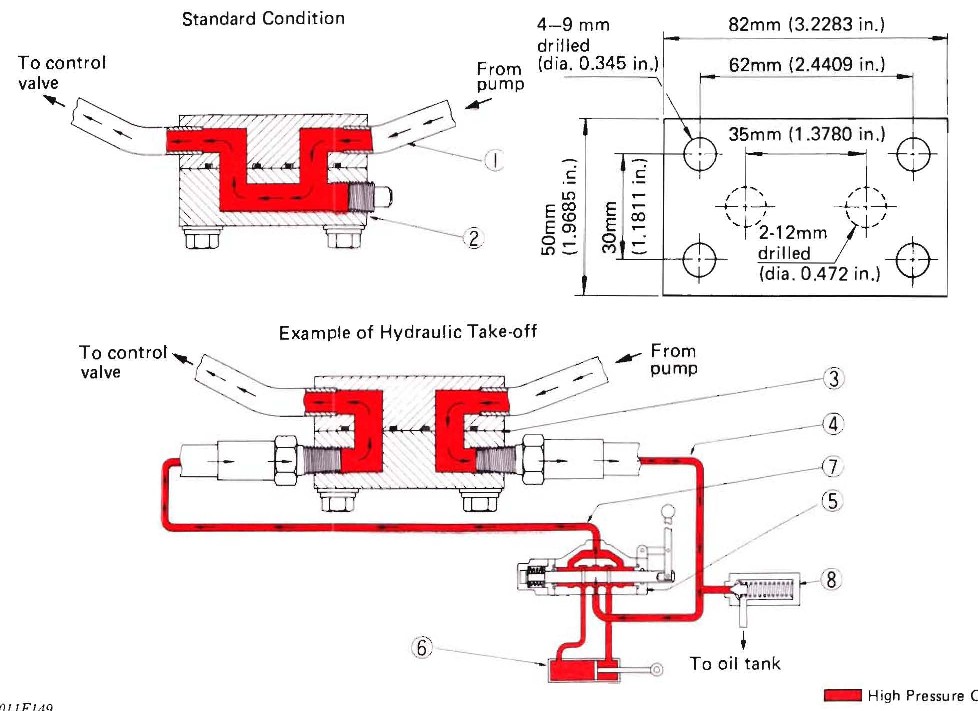

Why is the Power Beyond hose needed?

Ok, right now you have effectively piped the Tank line to the 3ph control valve instead of the Tank. When your Prince valve is in neutral, fluid simply flows through the open centre and on to the 3ph, just as if it was piped via a PB port.

However, when you operate your Prince valve and the cylinder reaches the end of its travel causing the relief valve to operate, the excess fluid goes to the 3ph control instead of the Tank. Let us say for the sake of argument that the Prince relief valve is set to 2,000 psi.

The 3ph spool valve is also open centre, so when it is in the neutral position the fluid flows into the tank and pressure on your hydraulic pump, Prince valve and cylinders is limited to a safe 2,000psi.

However, when the 3ph spool valve is operated, that open center is closed off. The only path to the tank is now through the 3ph relief valve. Let us say that is set to 1,700 psi.

So if both valves are operated at the same time, the relief valves are in

series and therefore the pressure on the hydraulic pump, Prince control valve, cylinders and all connecting lines could hit 2,000psi + 1,700psi = 3,400 psi!

At that pressure, it is very likely something will break. Hopefully something cheap like a hydraulic line and not something expensive like the hydraulic pump drive tang on the fuel injection camshaft.

So yes, you might get away with just 2 hoses and no PB adapter. But do you really want to chance it?