Here is where I currently am at on my L345DT TLB project. Symptoms: tractor is difficult to start at temps below 40F even with multiple extended glowplug activation (replaced all glowplugs) and an oil pan heater (the hose heater didn't work even though a multimeter indicated its should. However, when I got it out of the tractor it worked and I now suspect the previous owner had a 100% antifreeze solution). A dry compression test gave results running between 290-300 per cylinder. a wet compression test gave the same results. a leak down test averaged around 70% with most of the escaping air evident in the air intake and the exhaust.

When starting there is abundant black and white smoke until it fires up. After it starts there is NO noticable smoke out the exhaust and NO noticeable blow by at the oil fill port. My attempt to build a homemade blowby manometer according to internet instructions was unsuccessful, so I abandoned the project and moved on.

When I test drove the tractor (1300 hours) the previous owner had me kill it with the compression test. Operator manuals, as well as the decal below the decomp knob, say DON"T kill the engine with the decomp knob except for runaways or you are likely to damage the exhaust valves. I called the previous owner and he said for the year he owned the tractor he always killed it with the decomp knob.

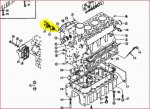

Therefore, I decided to pull the head after requesting that my wife pray that it is the valves and not rings, please, purty please. Attached are some piss poor pictures (620x230? whose bright idea is that) I poured some water in the intake and exhaust ports and both exhaust and intake valves on several cylinders leaked, not a stream, but stead drops.

My thoughts: It is time for to have a valve job. No indication of a head gasket leak. Waiting on a cylinder bore gauge to arrive. I was surprised by the gunky deposits in the cylinders, around the valve edges, and mostly in the intake port side prior to the valves. I am wondering if the injectors are not functioning to spec and due to be replaced, i.e. dribbling fuel or bad pattern? I also am wondering if they are the primary cause of the gunky deposits, the black/white smoke while cranking starting, and the oily intake ports and valves???

I have not removed the injectors because I want to find a new ones prior to removing the old ones. The local kubota dealer does not have testing equipment nor do they send them out...they just replace them because cost wise it make the most sense. Any good sources for L345 injectors?

What do the wizards of smarts think about the pics and deposits. Especially note the intake valve on cylinder #4 is actually leaving an impression in the piston build up deposit ( and to a lesser extent on #1). Finally, I would note that when I changed fuel filter I was amazed at the sludge in the filter. I guessed it was most likely water from tanks condensation over a long time. I drained the tank, added new fuel with Power Service, new filter, and bled the system. Any comments?

When starting there is abundant black and white smoke until it fires up. After it starts there is NO noticable smoke out the exhaust and NO noticeable blow by at the oil fill port. My attempt to build a homemade blowby manometer according to internet instructions was unsuccessful, so I abandoned the project and moved on.

When I test drove the tractor (1300 hours) the previous owner had me kill it with the compression test. Operator manuals, as well as the decal below the decomp knob, say DON"T kill the engine with the decomp knob except for runaways or you are likely to damage the exhaust valves. I called the previous owner and he said for the year he owned the tractor he always killed it with the decomp knob.

Therefore, I decided to pull the head after requesting that my wife pray that it is the valves and not rings, please, purty please. Attached are some piss poor pictures (620x230? whose bright idea is that) I poured some water in the intake and exhaust ports and both exhaust and intake valves on several cylinders leaked, not a stream, but stead drops.

My thoughts: It is time for to have a valve job. No indication of a head gasket leak. Waiting on a cylinder bore gauge to arrive. I was surprised by the gunky deposits in the cylinders, around the valve edges, and mostly in the intake port side prior to the valves. I am wondering if the injectors are not functioning to spec and due to be replaced, i.e. dribbling fuel or bad pattern? I also am wondering if they are the primary cause of the gunky deposits, the black/white smoke while cranking starting, and the oily intake ports and valves???

I have not removed the injectors because I want to find a new ones prior to removing the old ones. The local kubota dealer does not have testing equipment nor do they send them out...they just replace them because cost wise it make the most sense. Any good sources for L345 injectors?

What do the wizards of smarts think about the pics and deposits. Especially note the intake valve on cylinder #4 is actually leaving an impression in the piston build up deposit ( and to a lesser extent on #1). Finally, I would note that when I changed fuel filter I was amazed at the sludge in the filter. I guessed it was most likely water from tanks condensation over a long time. I drained the tank, added new fuel with Power Service, new filter, and bled the system. Any comments?

Attachments

-

34.6 KB Views: 428

-

31.8 KB Views: 419

-

32.4 KB Views: 414

-

31.3 KB Views: 408

-

34.5 KB Views: 408