retiree-urgency abandoned

Active member

Equipment

B3350, Kub. 5" rotary cutter, LP 48" forks, Titan Aerial Platform, KK XB Dump

I'd like to modify the pallet forks for my tractor (they mount to the front end loader using skid steer quick attach, SSQA) so that I could also be able to hang them on my Speeco 3 point quicktach on the rear of my tractor. There are aftermarket 3ph to SSQA adapters, but that's overkill/overcost for what I want to do (and per a buddy, the welds look really terrible on them) - I just want to get double-duty out of the forks I already have without adding another implement to my arsenal. Would allow me to go out into the field with everything I need - bucket on the front and forks w/aerial work platform carryall on the back.

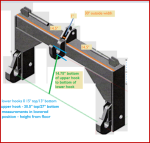

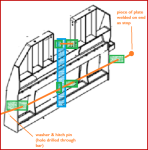

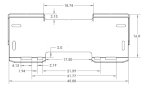

Here's what I'm thinking - weld some 3ph hangers with pins on the forks. I marked up the picture below. First I'd have some square stock (the blue) - welded up the center (maybe just a single piece on the tractor-facing side of the fork frame (rather than piecing it between the existing fork rails) - there's clearance in the middle so it shouldn't interfere with the SSQA. Then, I'd have flat plate cut into ears/tabs (the green squares) with holes (red circles) for the pin & bottom rail drilled in them. Rather than laying flat (per my drawing) to the frame, they're turned 90 degrees (going toward the tractor) - the top pair would catch a normal 3ph pin. The bottom 4 would catch a 1" solid steel tube - with a welded stop at one end and a washer and a sturdy R hitch pin outside of the other end tab to keep the rail in place. That way, for changeover from 3ph to SSQA, I just have to pull the hitch pin and remove the lower tube (weighs less than 15 lbs). The top pin is high enough that it wouldn't interfere with the SSQA when I'm using the forks on the FEL. To changeover from 3ph to SSQA, I'd just reverse these steps and no heavy lifting!

Of course you'd need to get the spacing right - height of tabs high enough so 3PH quicktach hooks (when lowered) would clear under the pin/rod to grab the forks, as well as depth clearance on the forks (size of tabs) for the hooks on the 3ph quicktach, so they grab clear of the fork frame. Parts list for this design:

1. 1" x 48" steel round (not hollow) for bottom rail. I found this with a little online research - https://fastmetals.com/search?q=1"+...gs_category:ALLOY/filter:tags_category:CARBON - the CARBON 1018 COLD FINISHED ROUND ASTM A108 with a welded stop on one end and drilled for a hitch pin on the other end. I could order this if Dusty can't get it.

2. 6 tabs/ears of sheet steel - 1/2" stock - size the tabs as needed (overbuild a little, please) for support.

3. 1 piece of square tube (5/15" or 3/8" wall), square solid or equivalent - what one can scrounge - maybe even a piece of beam or RR rail - size (2"x2", 3"X3", ?) to be determined for load - if tube, leave both ends open for ventilation

4. 1 1" inside diameter washer to go on bottom rail beside hitch pin

5. 1 (stout) R hitch pin for bottom rail

6. 1 3ph hitch pin (for top ears)

Would welcome your thoughts on this.

Thanks!

Here's what I'm thinking - weld some 3ph hangers with pins on the forks. I marked up the picture below. First I'd have some square stock (the blue) - welded up the center (maybe just a single piece on the tractor-facing side of the fork frame (rather than piecing it between the existing fork rails) - there's clearance in the middle so it shouldn't interfere with the SSQA. Then, I'd have flat plate cut into ears/tabs (the green squares) with holes (red circles) for the pin & bottom rail drilled in them. Rather than laying flat (per my drawing) to the frame, they're turned 90 degrees (going toward the tractor) - the top pair would catch a normal 3ph pin. The bottom 4 would catch a 1" solid steel tube - with a welded stop at one end and a washer and a sturdy R hitch pin outside of the other end tab to keep the rail in place. That way, for changeover from 3ph to SSQA, I just have to pull the hitch pin and remove the lower tube (weighs less than 15 lbs). The top pin is high enough that it wouldn't interfere with the SSQA when I'm using the forks on the FEL. To changeover from 3ph to SSQA, I'd just reverse these steps and no heavy lifting!

Of course you'd need to get the spacing right - height of tabs high enough so 3PH quicktach hooks (when lowered) would clear under the pin/rod to grab the forks, as well as depth clearance on the forks (size of tabs) for the hooks on the 3ph quicktach, so they grab clear of the fork frame. Parts list for this design:

1. 1" x 48" steel round (not hollow) for bottom rail. I found this with a little online research - https://fastmetals.com/search?q=1"+...gs_category:ALLOY/filter:tags_category:CARBON - the CARBON 1018 COLD FINISHED ROUND ASTM A108 with a welded stop on one end and drilled for a hitch pin on the other end. I could order this if Dusty can't get it.

2. 6 tabs/ears of sheet steel - 1/2" stock - size the tabs as needed (overbuild a little, please) for support.

3. 1 piece of square tube (5/15" or 3/8" wall), square solid or equivalent - what one can scrounge - maybe even a piece of beam or RR rail - size (2"x2", 3"X3", ?) to be determined for load - if tube, leave both ends open for ventilation

4. 1 1" inside diameter washer to go on bottom rail beside hitch pin

5. 1 (stout) R hitch pin for bottom rail

6. 1 3ph hitch pin (for top ears)

Would welcome your thoughts on this.

Thanks!

Attachments

-

250.7 KB Views: 245

-

984.5 KB Views: 239

-

155.2 KB Views: 249

-

909.6 KB Views: 248

-

92.8 KB Views: 247