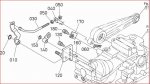

I have a B3030. Recently the linkage connecting the raise arm to the hydraulics system snapped. When it snapped the 3 point would no longer remain raised. There is a pin near the spline connection to the raise arm that I think should rotate and I thought it was stuck. It does not look right that it should not. Any thoughts? I tried to replace the linkage and it bent when I raised and lowered it but I salvaged the part before I bent it too much. I have attached a couple of pictures of the part in question.

Attachments

-

29.6 KB Views: 258

-

35 KB Views: 260