Inexperienced snow mover here who is dealing with snow in SW VA after two snowless winters in a row. So I'm also rusty. I need advice, ideally from folks who use a snow plow blade with a rubber edge on asphalt.

On my Kubota B2601, I have a B2672 front mount on my loader arms with a 5-foot snow blade. There’s a 1”+ thick rubber edge bolted to the blade that sticks down a couple inches. I manually change the blade angle, so on my to-do list is installing a front cylinder!

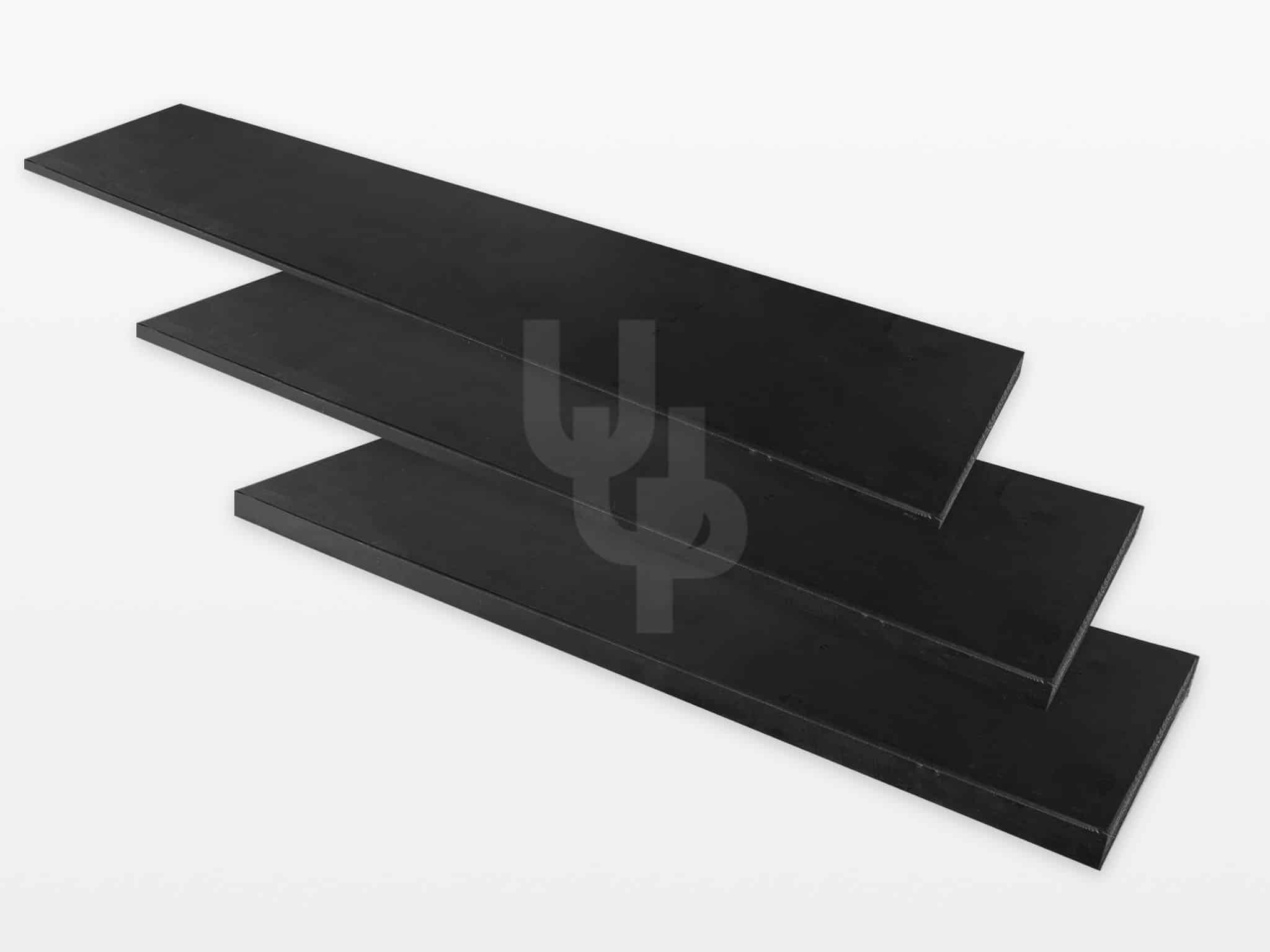

Yesterday I reversed the rubber edge because the edge I'd used during 2-3 winters was worn almost to the blade's steel. I'm unsure if this is typical wear from plowing my asphalt driveway or from plowing our daughter's and neighbors' gravel driveways. I think both. But my question is really about my own driveway because I've learned to keep the rubber 1-2" above gravel. Our asphalt is in decent condition but with some cracks, bumps, and patched places.

Our driveway is about 400' long and slopes up to the house at a 20%-plus angle. It takes a sharp turn toward the house at the top, and that curve is the steepest spot and the hardest to clear. Our little AWD cars wiggle going up with the slightest amount of snow. I suppose they'd do better with a snow pack, but delivery trucks wouldn't even attempt it. Ten days ago our propane delivery got aborted when the truck got stuck going up—after I'd plowed. I'd gotten the asphalt nicely clean, but afterward some white pines along the driveway dropped snow and ice. Just very thin patches in spots. And just in time for the truck to show up.

Given my driveway, am I correct in concluding I need to continue to use the rubber edge in contact with the asphalt and accept the resulting wear?

Second issue concerns technique—basically whether to use float or not. I haven't been and am not sure why. Whether I just forgot about it or didn't like the light front-end/steering issues. Maybe that was happening while plowing uphill. I only have 25 hp so can't move much going uphill, but I like to do a little to shorten the job slightly.

I've reviewed messages I saved from this forum and another on using float for plowing, and they were very divided and sometimes contradictory in the same message. The clearest recommendation I found was on Messick's YouTube channel on plowing with a bucket:

On asphalt, lower bucket to paving, level, put in float and scrape the surface clean.

On gravel, nudge bucket up a little and curl cutting edge up to keep from digging in.

What do you think about float based on your experience and about using the rubber in contact with the asphalt?