Hi, I've been going through this old 185dt, and noticed a bolt that won't seat, it sticks out a quarter of an inch or so and weeps transmission fluid. Looks like a set screw? It's about on the opposite side as the fill level bolt, similar height (right side, down by my right foot when seated). Can't find it on any of the diagrams.

L185DT: Wrong bolt in transmission?

- Thread starter nullptr

- Start date

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

I have the same bolt on my L185F on the brake pedal (right) side. I looked through the illustrated parts list and never saw anything that illus the right side of the case so have no idea what that was holding.

The bolt head is tight against the case on m and it is a few inches to the rear of where the oil level plug is on the opposite side.

here is the clutch side. Notice the red plug for oil level is right at the front of the foot rest

The bolt head is tight against the case on m and it is a few inches to the rear of where the oil level plug is on the opposite side.

here is the clutch side. Notice the red plug for oil level is right at the front of the foot rest

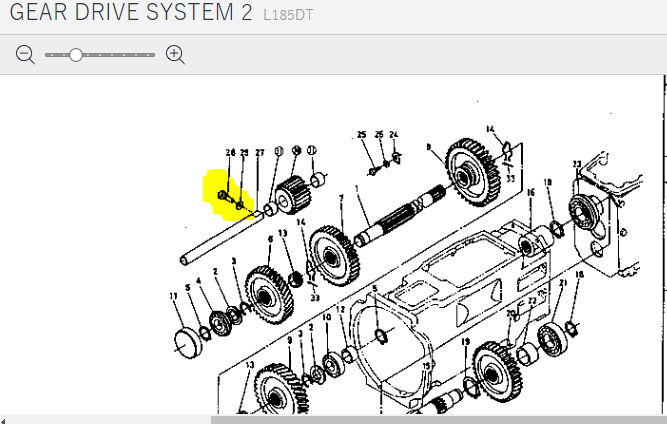

Find the diagram that shows the reverse idler and the shaft it rides on. I'll bet that bolt is a retainer for that shaft. When properly installed it fits over a flat spot on said shaft and keeps it in place.

You may need to remove a shift cover to see the shaft down in there. You may need to move the shaft a little to get into the right spot so the bolt threads in all that way.

You may need to remove a shift cover to see the shaft down in there. You may need to move the shaft a little to get into the right spot so the bolt threads in all that way.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

This has come up before If I remember right.

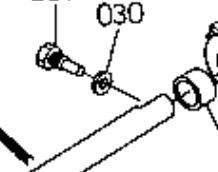

Looks like someone lost the original and replaced it.

It need to be shortend and replace the sealing washer with a lock washer.

Put a little RTV, or pipe dope on the threads just under the head to seal it up.

Looks like someone lost the original and replaced it.

It need to be shortend and replace the sealing washer with a lock washer.

Put a little RTV, or pipe dope on the threads just under the head to seal it up.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Thanks for the input, folks. Added the above screw to my next messicks order, we'll see how they compare.

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

Please post a picture of that when you get it please.Thanks for the input, folks. Added the above screw to my next messicks order, we'll see how they compare.

I was going to suggest that was the part but thought that reverse shaft would be rotating and couldn’t find any pictures to confirm what that part looks like.

I believe the problem is that the shaft that it retains has turned. Not allowing the set screw to go in all the way. I have had them where people took them out thinking it was the level plug. You may be able to put some sort of pic into the hole and rotate the shaft to the spot where the set screw will go in complete. The other problem may be that the shaft has moved forward or backwards.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

My problem with his bolt is that it has threads on the pin portion, which makes me think someone just made the pin out of a bolt and it's just too long.I believe the problem is that the shaft that it retains has turned. Not allowing the set screw to go in all the way. I have had them where people took them out thinking it was the level plug. You may be able to put some sort of pic into the hole and rotate the shaft to the spot where the set screw will go in complete. The other problem may be that the shaft has moved forward or backwards.

Will do, may be a couple weeks before I have enough stuff for an order.Please post a picture of that when you get it please.

I was going to suggest that was the part but thought that reverse shaft would be rotating and couldn’t find any pictures to confirm what that part looks like.

Russell King

Well-known member

Lifetime Member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

@nullptr

since you are new…

PM = Private Message and if you click on the name on the left of the post you can “start conversation” with that person. You can also use the envelope icon in the upper right corner but you have to start typing the user name in after starting the conversation

Sorry for the basic instructions but sometimes people just don’t know what we are talking about!

since you are new…

PM = Private Message and if you click on the name on the left of the post you can “start conversation” with that person. You can also use the envelope icon in the upper right corner but you have to start typing the user name in after starting the conversation

Sorry for the basic instructions but sometimes people just don’t know what we are talking about!

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

If it won't thread in and bottom out then you have to take the top off and get the shaft to line up properly to close the gap.

Looking at the diagram posted, it would appear to be the reverse gear that the shaft rides on, that the bolt holds in place.

I'd try to get the shaft to line up by jacking up and supporting the rear end, and then running the tractor in reverse to see if the shaft will spin slightly. Be ready with a screw driver or thin punch to shove in the hole to capture the shaft while you shut down the engine.

I'd try to get the shaft to line up by jacking up and supporting the rear end, and then running the tractor in reverse to see if the shaft will spin slightly. Be ready with a screw driver or thin punch to shove in the hole to capture the shaft while you shut down the engine.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

It already had a bolt tightened down into the shaft, so my bet is that it dimpled the shaft just enough that it's not goin to spin easily.Looking at the diagram posted, it would appear to be the reverse gear that the shaft rides on, that the bolt holds in place.

I'd try to get the shaft to line up by jacking up and supporting the rear end, and then running the tractor in reverse to see if the shaft will spin slightly. Be ready with a screw driver or thin punch to shove in the hole to capture the shaft while you shut down the engine.