I changed the coolant in the MX this past weekend and noticed that an idler near the A/C compressor belt wasn't making contact with the belt. There's no adjustment to get it into contact, only a bolt on the left side of the engine that is used to adjust the tension in the A/C compressor belt.

If you have an MX with cab and A/C or a similar tractor, can you check and see if you have the idler pulley, if it's in contact with the belt, and what size it is. I'm wondering if the idler pulley is too small, or if it's an artifact from some other feature on the tractor that isn't being used. I have the printed WSM and it says nothing about this idler.

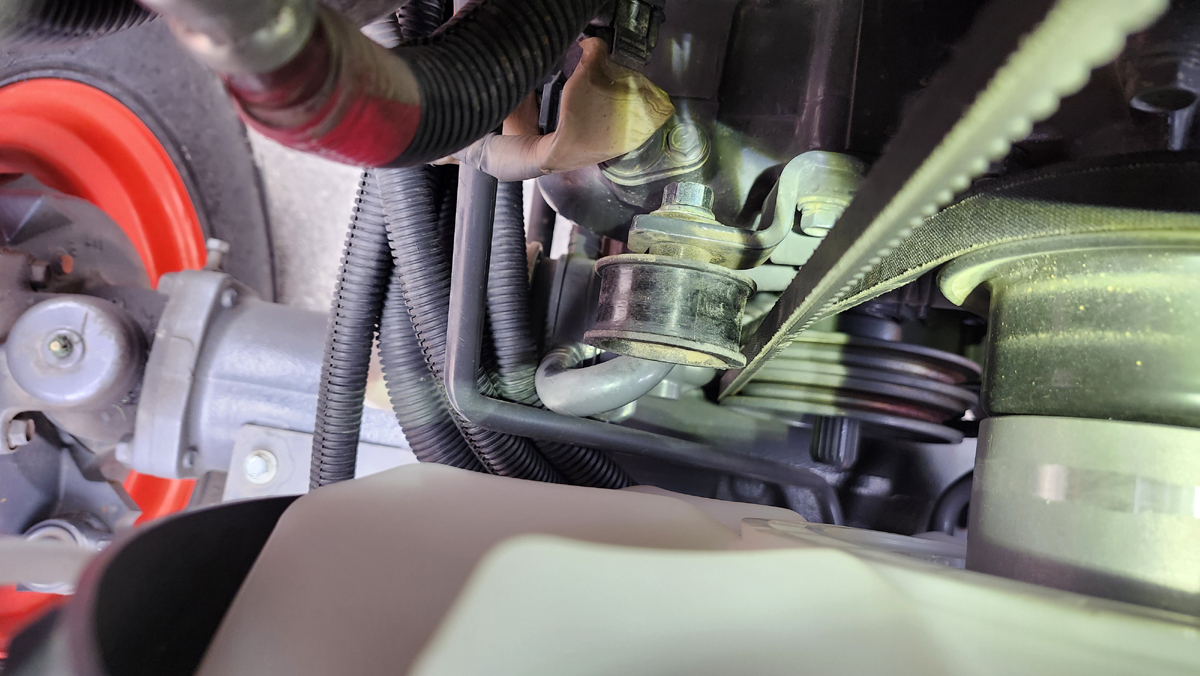

Idler in center of image not in contact with the A/C compressor belt.

Bolt to adjust A/C compressor belt tension (on left side of engine).

If you have an MX with cab and A/C or a similar tractor, can you check and see if you have the idler pulley, if it's in contact with the belt, and what size it is. I'm wondering if the idler pulley is too small, or if it's an artifact from some other feature on the tractor that isn't being used. I have the printed WSM and it says nothing about this idler.

Idler in center of image not in contact with the A/C compressor belt.

Bolt to adjust A/C compressor belt tension (on left side of engine).