My circa ‘96 M4700DT “Front Axle Bracket” and “Bushing”…. are not greaseable…. despite the Owner‘s Manual lubrication instructions and depicted Zerk/Grease-fitting….none exists on my bracket.

Research tells me I have an “early” bracket…which was superseded later with the greaseable type.

Question: Has anyone ever “worn out” their non-greaseable front axle bushing and/or bracket ?

Question: Has anyone drilled, tapped, and installed a Zerk fitting to convert their non-greaseable bracket/bushing ?

Kubota wants $290 for just the bracket and I have drills and taps.

The Messicks parts diagram offers “tips” from users on how to accomplish REPLACEMENT of the bushing. If I do this and the bushing is not worn-out, I plan to include drilling a grease-hole thru the existing bushing.

But the “Tips” state: “Need a sharp flat chisel and hammer for removal of the old one. Jack up tractor and put stands under it and get ratchet straps to put on the differential to suspend it. Will need to remove coupling on the drive shaft and remove drive shaft and unbolt the housing of the bushing”

I cannot imagine WHY one would need to remove the driveshaft…if the axle were supported with jackstnds and never dropped from the chassis.

Anyone with experience in this type of work …Have any comments…and/or answers….and/or suggestions?

Thank you.

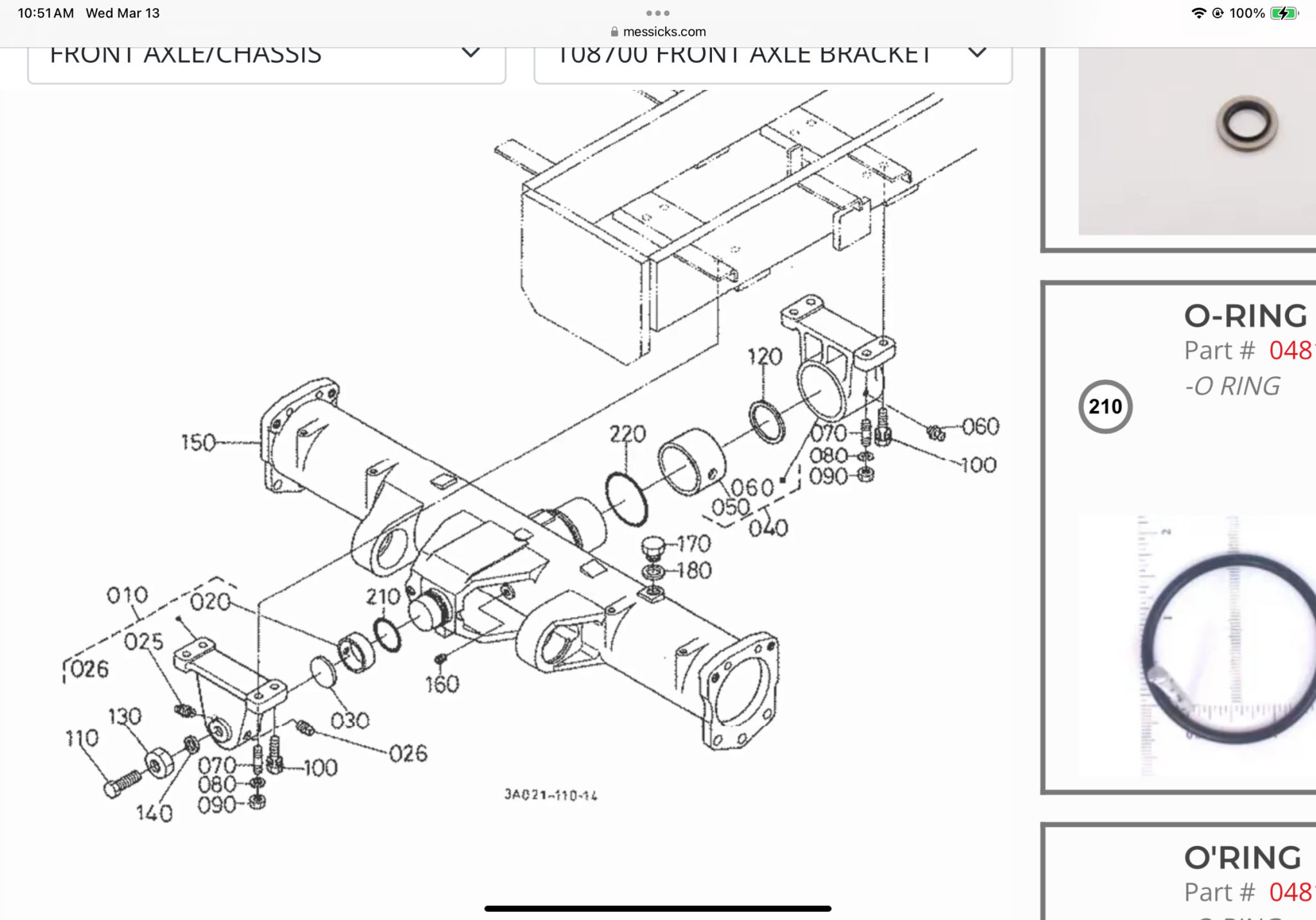

Items (10) and (20) are the parts being addressed. The replacement/superseded front bracket (10) is indicated in this illustration…. my earlier bracket has no grease-zerk or plug (items 25 & 26)

Research tells me I have an “early” bracket…which was superseded later with the greaseable type.

Question: Has anyone ever “worn out” their non-greaseable front axle bushing and/or bracket ?

Question: Has anyone drilled, tapped, and installed a Zerk fitting to convert their non-greaseable bracket/bushing ?

Kubota wants $290 for just the bracket and I have drills and taps.

The Messicks parts diagram offers “tips” from users on how to accomplish REPLACEMENT of the bushing. If I do this and the bushing is not worn-out, I plan to include drilling a grease-hole thru the existing bushing.

But the “Tips” state: “Need a sharp flat chisel and hammer for removal of the old one. Jack up tractor and put stands under it and get ratchet straps to put on the differential to suspend it. Will need to remove coupling on the drive shaft and remove drive shaft and unbolt the housing of the bushing”

I cannot imagine WHY one would need to remove the driveshaft…if the axle were supported with jackstnds and never dropped from the chassis.

Anyone with experience in this type of work …Have any comments…and/or answers….and/or suggestions?

Thank you.

Items (10) and (20) are the parts being addressed. The replacement/superseded front bracket (10) is indicated in this illustration…. my earlier bracket has no grease-zerk or plug (items 25 & 26)

Last edited: