I have an older B7500 that I bought used. It had been worked pretty hard before I acquired it. Anyway, the 3PH has never raised as high as I would expect. For example, I have a 4' Bush Hog that when adjusted for level at the bottom only raises about 8" off the ground when the lift harms are raised fully. I realize I can get more lift by adjusting the top link, but doing so changes how the hog is positioned at ground level.

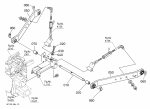

I looked to see if the feedback rod needed adjustment and I think I've got that sorted just fine. However, I note there appears to be lots more downward travel available (at least 8" below ground level), which has me wondering if I'm simply not getting as much rotation out of the lift harms as is available. That is, the arms are currently oriented to go lower than they need to but not as high as they should. Is it reasonable to think I could remove the lift arms, rotate them, then reattach them in a way to have more upward rotation and less downward?

Thanks much.

I looked to see if the feedback rod needed adjustment and I think I've got that sorted just fine. However, I note there appears to be lots more downward travel available (at least 8" below ground level), which has me wondering if I'm simply not getting as much rotation out of the lift harms as is available. That is, the arms are currently oriented to go lower than they need to but not as high as they should. Is it reasonable to think I could remove the lift arms, rotate them, then reattach them in a way to have more upward rotation and less downward?

Thanks much.