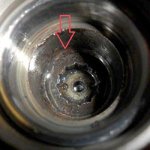

There is no point in changing the housing of the water separator at this point unless it is cracked or something. The screen in the water separator is probably also fine.

The water is likely sitting in the bottom of the fuel tank, waiting to cause problems at some future point. For that model, I don't know a convenient method of draining the fuel tank from the bottom, but you could discuss with your dealer. The other two possible ways would be to install a water worm to get it out, or if the design of the fill tube lets you put a clean tube in, siphon all the fuel out, and replace with clean dry diesel. The cost of these items is much less than the cost of the high pressure pump etc.

Then change the fuel filter and clean the water separator. Follow directions in operators manual to remove air from lines. No this does NOT require cracking the injector lines