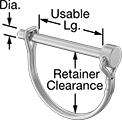

That’s PRETTY WORK! Thanks for sharing.That would be nice but the way the LA525 is welded up makes adding the flanges difficult. Here is a quick and dirty of what I am contemplating. Pin would be retained in the loader arms with two HD external snap rings. I have several mill lengths of 1" 1045 TGP in the rack which is a dead fit in the arms so all I need do is part off to OAL, groove, counterbore, and drill and tap for the grease fitting. Probably 30-45 minutes including setup to make a pair.

Dan

EDIT: This wasn't on the schedule for today but since things got chatty I added it. Here are two new pins ready to be drilled and tapped. About as easy as it gets.

BTW, when I purchased Quick-Attach adaptors for my FEL similar to the original Kubota style, I installed the pins and (ignorantly/forgetting to follow my own advice) tightened up the locating-bolts until they were snug. Some months later, while re-reading the Operators’ Manual I was reminded the bolts are supposed to be “loose” ..not tight… so I went out to re-examine them.

Guess what? The bolts, even tho’ snugged tight,… still allow the pin to move,…as the bolt-hole thru the pins is oversized and therefore a snug/tight locating-bolt cannot prevent the pin from having ample movement. doh.

My guess is that a roll pin or any pin/bolt/etc which was staked even…would perform just as well.

But, obviously, if the bolt head or nut were sheared off completely by rough-useage…then it would be likely to be lost…. same as lock-rings(although the shearing action would have to occur in a different manner.)

Last edited: