I purchased a b2710 with a broken range shift. It only had 450hrs and the previous owner had left it in high for years after it broke. I wasn't ready to spent a lot on a newer machine, so this seemed like a good opportunity to buy something to repair. Mud season finally arrived so I ordered what I thought was broken, removed the loader, and got the tractor in a barn.

When I started looking at the repair more carefully I couldn't find any pictures of the range shift assembly or a log of anyone else splitting this model, so I wanted to share what I found in case anyone has similar issues. I don't suggest following my steps or assuming that I've done anything correctly, since I'm not a kubota technician or any sort of expert on much of anything at all.

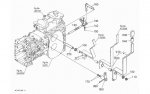

The range shift lever was loose, but the external roll pin was not broken. The lever would move freely and occasionally have some resistance. I found that the range arm shift lever (6C170-18510) was bent in two directions. Since it was bent it also caused small damage to the range shift fork (6C070-18420) which was replaced, along with the rod it runs on (6C070-18410), and its detent ball and spring. Replacing the rod and spring/ball wasn't strictly needed, but I ordered them before in case they were somehow damaged. These are parts 120-160 on kubota's drawing. I re-sealed the split cases with permatex anaerobic gasket maker #51813, waited a day, and refilled with UDT2. The range shift functions well. I suggest being very careful with the 3pt lift assembly- I introduced or disturbed a tiny piece of debris which resulted in it lifting slowly. This was resolved by removing it, tearing down, and cleaning the valve body.

parts 120-160 were ordered

sheet metal and seat support off.

the range section is slightly red. The nuts on its left were removed to split.

differential, rear axle, and range were moved backwards on a rolling jack to stands

bent lever was replaced

Hope that helps someone in the future,

Pete

When I started looking at the repair more carefully I couldn't find any pictures of the range shift assembly or a log of anyone else splitting this model, so I wanted to share what I found in case anyone has similar issues. I don't suggest following my steps or assuming that I've done anything correctly, since I'm not a kubota technician or any sort of expert on much of anything at all.

The range shift lever was loose, but the external roll pin was not broken. The lever would move freely and occasionally have some resistance. I found that the range arm shift lever (6C170-18510) was bent in two directions. Since it was bent it also caused small damage to the range shift fork (6C070-18420) which was replaced, along with the rod it runs on (6C070-18410), and its detent ball and spring. Replacing the rod and spring/ball wasn't strictly needed, but I ordered them before in case they were somehow damaged. These are parts 120-160 on kubota's drawing. I re-sealed the split cases with permatex anaerobic gasket maker #51813, waited a day, and refilled with UDT2. The range shift functions well. I suggest being very careful with the 3pt lift assembly- I introduced or disturbed a tiny piece of debris which resulted in it lifting slowly. This was resolved by removing it, tearing down, and cleaning the valve body.

parts 120-160 were ordered

sheet metal and seat support off.

the range section is slightly red. The nuts on its left were removed to split.

differential, rear axle, and range were moved backwards on a rolling jack to stands

bent lever was replaced

Hope that helps someone in the future,

Pete

Attachments

-

136.2 KB Views: 1,274

-

138.3 KB Views: 1,396

-

121 KB Views: 1,278

-

70.5 KB Views: 1,210

-

82.5 KB Views: 2,400