Hi all,

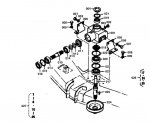

Now that mowing season is over, I am taking the time to work over the RCB60-I belly mower on my new-to-me B8200DT. Primary task is to repair the gearbox powered by the front PTO shaft. The manuals call for 90W gear oil for lube, but the seal is gone - just leaks out in a puddle.

I have the gearbox pulled and separated from the lower jack shaft. Just need to get the pulley off to reach the lower seal. My three jaw pulley fits this job pretty well. I've tapped on the shaft and applied lots of PB Blaster. I sure don't want to bend the pulley, as Messicks is pretty proud of their new ones (Part #70712-99750, $102.88)

It's not rusty and I'm not wild about heating it with 'the gas wrench' unless I have to. What is the secret handshake to getting this thing to pop loose?

thanks,

Doug

Kingston, TN

Now that mowing season is over, I am taking the time to work over the RCB60-I belly mower on my new-to-me B8200DT. Primary task is to repair the gearbox powered by the front PTO shaft. The manuals call for 90W gear oil for lube, but the seal is gone - just leaks out in a puddle.

I have the gearbox pulled and separated from the lower jack shaft. Just need to get the pulley off to reach the lower seal. My three jaw pulley fits this job pretty well. I've tapped on the shaft and applied lots of PB Blaster. I sure don't want to bend the pulley, as Messicks is pretty proud of their new ones (Part #70712-99750, $102.88)

It's not rusty and I'm not wild about heating it with 'the gas wrench' unless I have to. What is the secret handshake to getting this thing to pop loose?

thanks,

Doug

Kingston, TN

Attachments

-

62.6 KB Views: 596

-

54.4 KB Views: 1,691