Hello fellow Orange Tractor Owners... I've stalked these threads during my brief stint as a Kubota owner to answer most of my questions so far... but I have come to the point where I could really use some advice/direction.

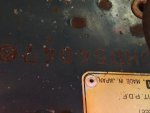

Firstly a little background. I recently purchased a Secondhand Kubota B7100D HST Serial number B7100HD54847 Proud as punch I was as I set about taming the tall grass on our section using the Tractor and the PTO driven Mulching mower that came with it. Everything was working superbly for a couple of hours and then the PTO started making a terrible noise! Long story short... I have disassembled the tractor to the point that I have found (and can clearly see) the problem, See Pics attached. But I am now stuck on how to actually disassemble the transmission and extract the various shafts and cogs so that they can (hopefully) be replaced. The work shop manual says "Disassembly is evident after reference to Figs 74 and 79" but I have to admit to being a bit stumped on how to proceed with the disassembly.

Can anyone offer any advice on how to proceed or point me in the direction of a resource that might help explain what to do?

Any and all help greatly appreciated

Firstly a little background. I recently purchased a Secondhand Kubota B7100D HST Serial number B7100HD54847 Proud as punch I was as I set about taming the tall grass on our section using the Tractor and the PTO driven Mulching mower that came with it. Everything was working superbly for a couple of hours and then the PTO started making a terrible noise! Long story short... I have disassembled the tractor to the point that I have found (and can clearly see) the problem, See Pics attached. But I am now stuck on how to actually disassemble the transmission and extract the various shafts and cogs so that they can (hopefully) be replaced. The work shop manual says "Disassembly is evident after reference to Figs 74 and 79" but I have to admit to being a bit stumped on how to proceed with the disassembly.

Can anyone offer any advice on how to proceed or point me in the direction of a resource that might help explain what to do?

Any and all help greatly appreciated

Attachments

-

92.8 KB Views: 448

-

92.6 KB Views: 432

Last edited: