Just bought a B3030 with steering problems. No steer at all, unless you raise the front end with loader. 480 hours. I am trying to determine if it is in the steering controller or pump. $1000. Which pump provides pressure to the controller and if pump was bad, what else on that pump circuit would not work. Have a hydraulic pressure gauge on order to jump into it but thought I would get some opinions first. Is it normal for a steering controller to go bad with that number of hours. Changed all fluids and used Kubota filters. Has any one ever replace one? How hard was it? Mine is a cab model, if that makes any difference.

B3030 steering problems, help

- Thread starter john11139

- Start date

I don't have time to ask more or reply to specifics now, here is the workshop manual, may have some test info etc, hopefully others can chime in.

http://www.kubotabooks.com/AutoIndex/index.php?dir=Tractor%20Owners%20Manuals/

http://www.kubotabooks.com/AutoIndex/index.php?dir=Tractor%20Owners%20Manuals/

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

If the loaders working then the pump is fine, the whole system runs off of one pump.

If you can pick up the front end and the wheels steer fine, then it's most likely a blown center seal, and yes that seal can go at any time regardless of hours.

The seal is an easy fix, remove the tie rods and the lines then the cylinder and pull it apart adn replace the seal.

If you can pick up the front end and the wheels steer fine, then it's most likely a blown center seal, and yes that seal can go at any time regardless of hours.

The seal is an easy fix, remove the tie rods and the lines then the cylinder and pull it apart adn replace the seal.

Attachments

-

25.7 KB Views: 1,755

As long as it is not the steering controller. I plan on tearing into it this week end. I was under the impression that it had two pumps. One for the hst and another one that controlled the power steering and pto clutch. Am I wrong. Thanks for both responses and the link to the manual.

I put a pressure gauge on I, 1,800 psi. Tore cylinder off, seal is blowed. Will order parts soon. Thanks for the helpAs long as it is not the steering controller. I plan on tearing into it this week end. I was under the impression that it had two pumps. One for the hst and another one that controlled the power steering and pto clutch. Am I wrong. Thanks for both responses and the link to the manual.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

The HST Pump is all internal it does nothing except move the tractor.As long as it is not the steering controller. I plan on tearing into it this week end. I was under the impression that it had two pumps. One for the hst and another one that controlled the power steering and pto clutch. Am I wrong. Thanks for both responses and the link to the manual.

The Hydraulic pump runs the entire system, it is a 2 section pump that half of it runs the loader and three point and the other half runs the steering and PTO controls.

I have a B3030HSD with a similar steering issue. I’ve removed the cylinder and rod.If the loaders working then the pump is fine, the whole system runs off of one pump.

If you can pick up the front end and the wheels steer fine, then it's most likely a blown center seal, and yes that seal can go at any time regardless of hours.

The seal is an easy fix, remove the tie rods and the lines then the cylinder and pull it apart adn replace the seal.

Parts to order?

In terms of parts to completely rebuild seals and gaskets, would I need to order the following parts?

Does anyone know if there’s a rebuild kit available?

I’ve also posed these questions to Messicks and Coleman.

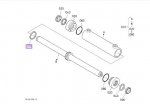

Parts I’m considering (also see screenshot):

2 quantity:

* 30

* 40

* 60

1 quantity 50 - assuming that 50 is the center seal.

The existing 20s are discolored, but given the price of replacing those, I’m considering reusing them.

Although not shown on this diagram, I also plan to reuse the two snap rings/clips that retain parts 20 in the cylinder holder.

It looks like the total of the parts listed above will be around $190 without shipping.

Since a complete cylinder with parts appears to run $800 or more, I’d like to go the rebuild route unless the design of the original cylinder is flawed and I should expect it the replacement seal to fail relatively quickly. (I got about 600 hours on the original).

Removing the cylinder

BTW, removal of the cylinder was challenging for me. The workshop manual didn’t offer much detail. Here’s what I did:

1/ Removed metal guards.

2/ Removed supply lines.

3/ Removed steering linkages from wheel carriers (I had to pull the top of the linkages up and to an angle to force the bolts to not spin so that I could remove the slotted nuts).

4/ Removed snap rings/circuits from the outer side of each part 20 (cover - rod) shown in the diagram above.

5/ Used wrenches on each of the tie rods and ended up loosening and removing the right hand tie rod.

This is the point where I was challenged. Although I could rotate the cylinder, it would not easily move laterally. Given that the left carrier has a cutout for the supply line attachments to slide through, it was clear that I eventually needed to pull the cylinder out the left carrier to the left (from operator’s perspective).

After spraying some lube around the part 20s, I ended up pulling the rod along with the still attached left tie rod to the left several times which broke loose part 20 on the left and removed part 20 and the entire rod from the cylinder.

Next, from the right side of the tractor, I was able to knock the right part 20 and the cylinder toward the left of the tractor. The right part 20 fell to the floor. Then the cylinder was able to be slid through the left carrier.

Attachments

-

198.6 KB Views: 79

-

649.9 KB Views: 89

-

506.3 KB Views: 89

Last edited:

You might be able to take your cylinder to a local hyd. repair shop and see what they charge for parts and assembly. You might be suprised!!