Wildfire

Active member

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

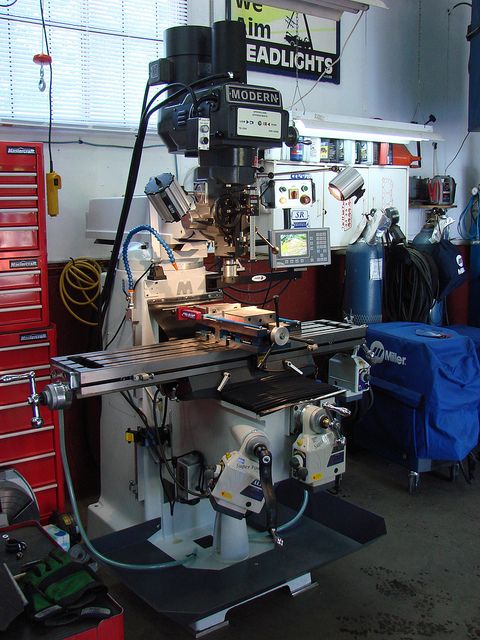

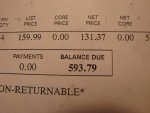

Some more pics. This is how the original poster should do his bucket to save it from further damage. First pic shows how the carriage bolts look under the bucket. In the last photo you can see the row of nuts along the top of the cutting edge.

Attachments

-

19.3 KB Views: 496

-

96.1 KB Views: 520