Thanks everyone for your input.

I feel that I have the tools to build a FEL if I could get the parts as a kit.

I don't think you are going to find a B6000 FEL kit.

I used 4 double-acting cylinders with a 16" stroke, a open spool control valve capable of handling two circuits with "power beyond". I couldn't find a control with all the features I wanted (single lever joystick, boom float, tip regen) locally, so I bought that on eBay. I measured the required hose lengths to the nearest foot after the fact and bought off-the-shelf hydraulic lines from the same supplier I got the cylinders from.

I had access to a metal supplier that will sell part-lengths of material. I used 3" x 2" rectangular, 3" and 1" square tube of various wall thicknesses, 1/8", 1/4" and 3/8" thick plate, 1/4" thick angle iron, 3" x 1/4" flat bar, 1" round bar stock, DOM tube and a variety of fasteners, mostly Gr.8 nuts and bolts.

I used a 4" x 6" bandsaw, 5" grinder with both grinding and cut-off disks, 12" cut-off saw, die-grinder, sawsall, oxy-acetylene torches, MIG welder, stick welder, small mill and small lathe. Some of those are optional -- there's always more than one way to skin a cat.

I have a nice flat poured concrete surface to work on, but it's off-level (for drainage) so I used an electronic level that can be zeroed at the touch of a button and a couple of squares to ensure things were straight with the machine as I went along. I started by taking basic measurements of the machine and mounting points. Then I sketched out various ideas, with scale measurements, as a guide. Once I settled on my design, I made a list of materials to buy.

I don't know what of the above are available to you on your island, but if you have similar resources then you can build your own without a specific kit.

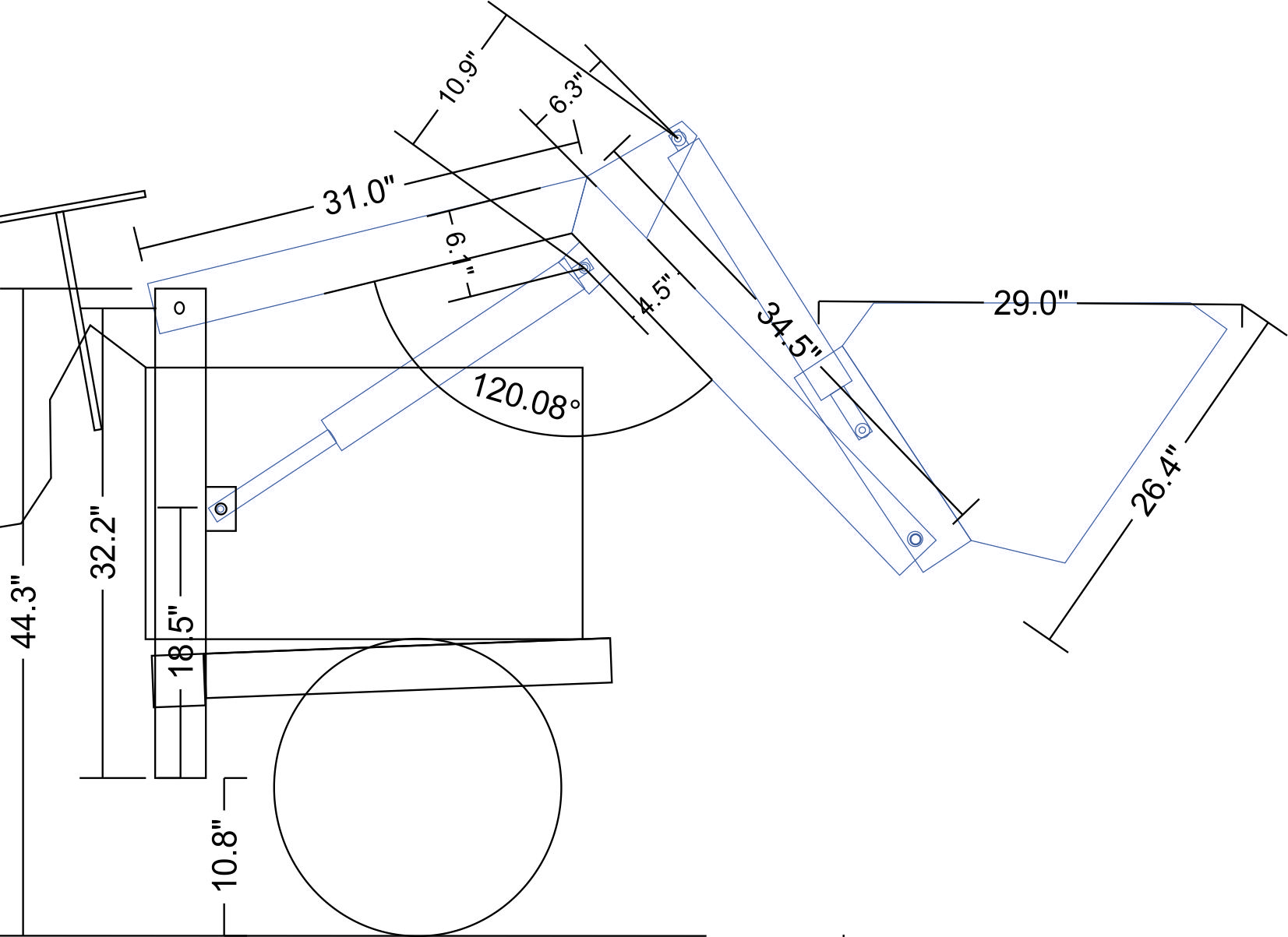

FWIW: here is my final sketch for my B7100. It would not necessarily fit your B6000, and I think some of the actual dimensions were tweaked during construction, but it would probably be close to the right size.