Wow - very impressive indeed!!!

Super job. I commend your skills!

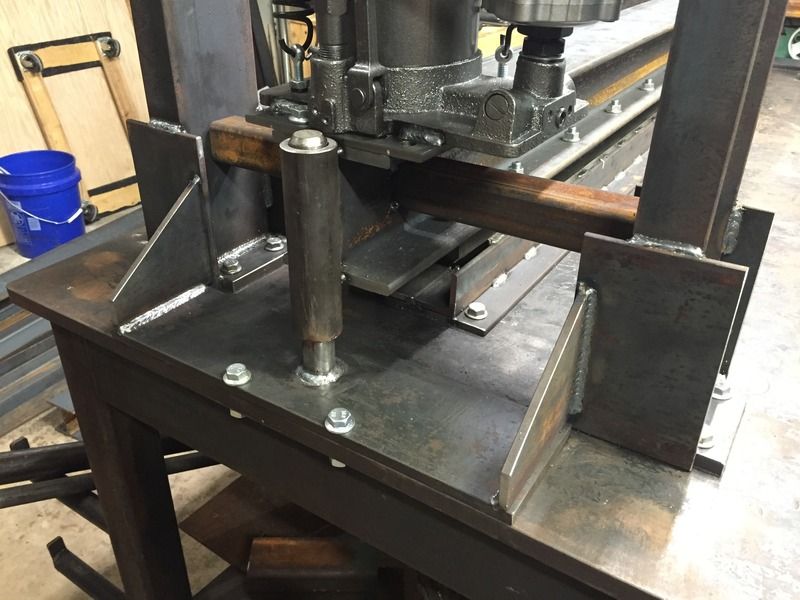

We've had some guys here with some amazing projects. I think your BIG homemade press brake is a first.

Thanks! Wasn't looking to make anything special, but when I looked at what it would take to do what I needed, it took it's own course and turned out to be much more capable than I imagined. Now looking at making custom bumper dies using the press, should easily be one of the most efficient machines I own when it comes to cost vs profit.

Really nice work!

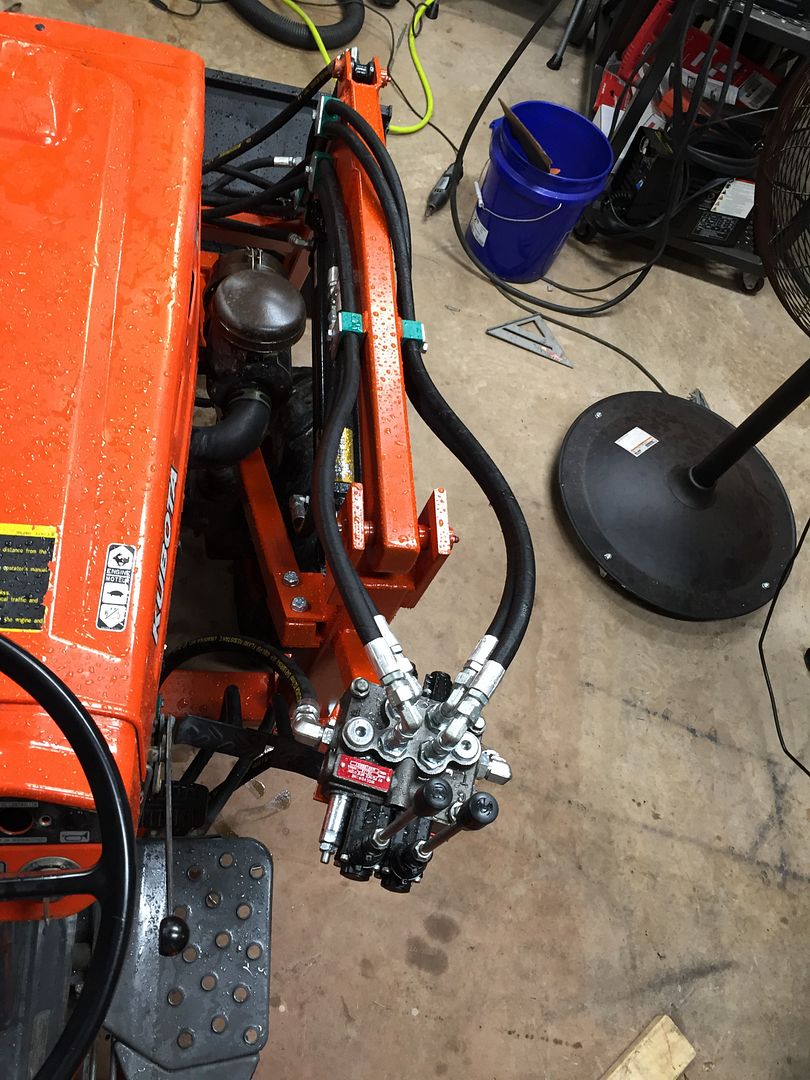

Is your FEL made to any drawings or are you making it up as you go?

Do you have any subframe going back to the rear axle or are you bolting the FEL to the existing frame only?

Cheers!

Hasse

Thanks! My father-in-law had prints but they were for a different tractor. I used what I could from them, but most of this kit is custom (not one piece is exactly the same as the prints). That said, it would have been easier to start from scratch instead of modifying someone else's design to work. And no, the kit doesn't attach to the rear axle. It will have supports that connect to the bar on the front of the frame, I'll post pics when it's done.

I like your press brake! What are you using to power it? Looks like a couple of pneumatic over hydraulic pumps. I built a leaf brake years ago with that type of pump and it is still working today with no issues.

Mind if I make a suggestion to improve your brake? Installing a truss rod on the top beam and putting a slight 'crown' in it will help the longer sheets from 'canoeing' in the center. Would be an easy mod.

Thanks! You're correct, it uses two air/hydraulic 20 ton jacks to power it. That's a great suggestion too, but this was designed to do tight radius bends at short distances (bumper work). I have changed the design, though, after bending the bucket. When the material comes in, it will have two 1"X6" cold rolled plates sandwiching the die. This will be more than strong enough to keep up with 40 tons of force, while allowing for very aggressive bend geometry on thick gauge pieces.

Concerned that the hydraulic tank or whatever it is you've placed at the grill is going to cause major over heating issues.

Looks like this has already been covered, but to confirm, that's the grill that came with the tractor.

So how much are you selling FELs for? :-D

Sent from my XT1254 using Tapatalk

Certainly something I'm looking into. After reading some of the terrible stories of QC and customer service on some kits, I'll be seriously considering starting a small line of these loaders. Any suggestions on a reasonable price point is greatly appreciated.

Hi, top class build, would you have any pics of the loader subframe, cheers

Thanks! These are the only other pictures I have at the moment

Is the finished build in the final photo by coachgeo the same FEL as the OP's partially finished build? If so there were some changes along the way -- including the tractor it's mounted on.

No, that's someone else's pic.