i saw in a video somewhere there was a b7100 with dual rear ag tires on it. i was courious to know if that was something home made or a actual set up? i would like to get them for mine if at all possible. do i have to get another hub, or axels? and how easy is the conversion?

b7100 dual rear ag tires?

- Thread starter stylo

- Start date

Randyj

Member

Equipment

B9200D / BF350 Kubota Loader / L-4530B Kubota Backhoe w - subframe / LP GS1548

truth be told...........absolutly nothing besides a cool lookin tractor. although a guy i work with wants to try to have a quad vs tractor tug of war and i figure i might get better traction.

ok.......i think you have changed my mind mingy haha. unless i can pick up a cheep set of used ones ill stick with the singles. thanks tho.

Keep an eye on craigslist and local auctions - you may find something used and inexpensive if these are not going to be your primary working tires.ok.......i think you have changed my mind mingy haha. unless i can pick up a cheep set of used ones ill stick with the singles. thanks tho.

It may not be friendly on the wallet but it does look cool.

Attachments

-

90.5 KB Views: 2,499

bulldog thats sweet!!! how did you do that? i think i might have figured it out. my rear axel has another set of holes further in. i think if i unpin the hub and silde it back and re pin it, it will work maby?

Stylo, I just robbed that pic from another post. It's in the off topic section. There was a discusion about duals here a while back. If I remember correctly Service Dept Vic told how to add duals the proper way. I thought the same as you on sliding the hub in on the axle. I believe he said it takes different wheels that are made to be bolted together. I don't think even with sliding your hus all the way in you still won't have enough room to add another set due to the dish on the wheels. It would be easy to try though. All you would need to do is jack the back end up and try both your wheels on one side. I saw a video on you tube that had a big Kubota pulling a bat wing and it had duals on it. Talk about beefy looking.

oh ok. well thanks for the tip bulldog! ill have to give it a whirl. ill have to find a set of ag's tho which has been proveing to be a bit hard. i just started stripin the tractoe down so when i get this loader problem figured out ill get to that.

I know this is an old post, but it's only on the second page of this section, and I thought it might be interesting to some of you if I posted what I've done. Out of laziness, this is copy and pasted from another forum. Because of one of my citations, you should be able to find it if you look, but I'm not trying to plug another forum.

It's copied verbatim, so the audience is slightly different. As reference: A YM2000 is a 20 PTO horsepower 2 wheel drive gray market tractor. The American version is the YM240, different only, in the American version, a 2 speed rather than 3 speed PTO with overrunning clutch, and a reversed throttle linkage.

A couple weeks ago, my girlfriend succumbed to my recent spate of tractor activity, and learned to drive some of my equipment. She really enjoyed it, and has been wanting to grow a "BIIIIIIIIG garden." After she looked some, she now has a YM2000 to do her gardening with! It's all hers, and I'm really proud of her. I think it's kind of redundant, given my plethora of tractors at the moment, but I am NOT going to argue!

The tractor was apparently used at a nursery to pull carts between their rows of plants and do general service/grading type work. It was VERY narrow. A quick test with my smallest disk harrow yielded acceptable results, but it felt really unstable for a new, inexperienced operator, particularly without any ROPS. I wanted to be able to pull my larger disk, though, but it is set up for my larger tractor and is fairly tall on the attachment points for the lower links.

I reversed the rims, and set them out to their widest, which worked much better, but the narrow rice tires combined with the geometry of the disk's 3 point attachment tended to hold the rear end up, and it would easily get stuck, slowly churning holes in the ground, especially when combined with delayed application of the differential lock, and tardy lifting of the implement when the tractor started to slip excessively. (Again, primarily operator inexperience on her part.)

While the correct solution would probably be to replace or revise the attachment points of the disk, and, especially, more thoroughly train the operator, that seemed like a rather boring solution to the problem. I scrounged around a bit, and found some Schedule 80 pipe and 1/4 inch plate. The other addition to this tale is that the girlfriend didn't just get a YM2000. She also ended up with this:

It's a Mitsubishi D1800. (It used to have ag tires on it, but we're getting to that part.) Before all this occurred, I was looking for ag tires or R4 tires for my loader-equipped YM240. I happened to find a set of R4 tires, brand new and never mounted, on (I was told) Kubota rims with a 6 on 6 inch bolt pattern, which won't match my YM240. They do, however, match this Mitsubishi. I had the tire shop swap the R4s for my turf tires on their respective rims, and mounted them up to each tractor. Now I had a spare set of rice tires that were only a tiny bit shorter than those on the girlfriend's YM2000. (Everybody thoroughly confused yet?)

I cut a set of four round plates from the steel plate, and drilled holes to mount to the Mitsubishi pattern wheels in two, and the Yanmar rims in two. Then I cut the tubing, trued it up, and welded them together to get a pair of these:

Sorry for the crummy picture, all I had until this evening was my cell phone for photographs.

After re-reversing the Yanmar wheels to their narrowest setting, I put the spool over the wheel and tightened it up with some longer bolts. Then, I put the Mitsubishi wheels onto the spool, at their widest setting. After it some grunting and a couple trips to the hardware store for fasteners, it looks something like this:

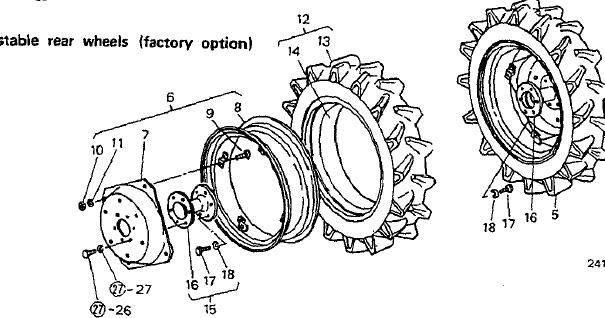

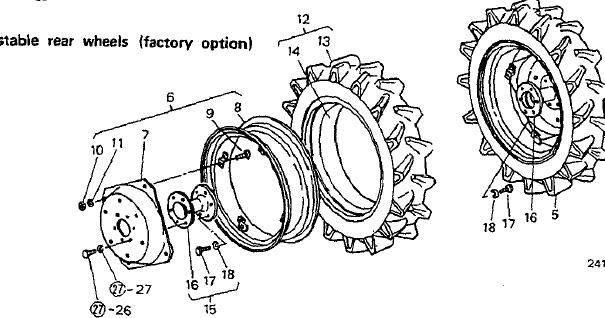

The overall width is just under 64 inches outside to outside. My YM240 (The same tractor) with factory Yanmar turf rims is just under 60 inches. Yanmar originally made this same sort of thing:

(Robbed from California, who cites the optional equipment portion of the operation manual, here:http://www.tractorbynet.com/forums/y...-narrow-2.html)

When it's all said and done, the outer duals sit up from the ground about 3/4 of an inch on pavement, so there is no additional stress on the axle shafts or bearings whatsoever on hard surfaces. In soft terrain, when tire slippage is an issue, the major force they add is forward as tractive effort.

I don't see any major risks to the tractor's longevity or durability, or, especially, safety. In soft ground situations where they only deliver torque, the tractor is operating with no more load than it would in high-traction situations. Even in soft soil, the additional bending moment of the wider wheels must be virtually negligible anyway, and, besides, the tractor was originally engineered to handle dual rear wheels.

This setup will only reduce the force the tractor would see compared to that. Safety wise, the tractor is wider. That makes it less tippy. This setup isn't as stable as it would be if the tires on the outside were in contact with the pavement, but it's not as bad as the wheels at their narrow setting alone.

The failure mode of this apparatus compared to the regular tractor without duals would be to lose the outer wheel(s). The spool is bolted to the hub over the original wheel, so whatever happens, the inner wheel will stay put. Breakage of the inside wheel, or the hub would/will occur, but with no greater likelihood than without the duals, since realistically speaking there is no more force than in the original engineering specification, and, in fact, this design actually would be less than designed for.

Even so, a disclaimer: Please, please, please, nobody look at this project and decide that since some stranger on the internet did this to their tractor it must be a good idea for you to do the same. This has not been engineered beyond literally scratching soapstone onto concrete and mulling in my head. I am a competent weldor, and this will not break my tractor. I have no idea about you, or your abilities or tractor's capabilities. I used what I did because that's what I had. That is not how you should do it. If you need some stranger's advice on how to do something that puts yourself and others in jeopardy, you shouldn't try to do this yourself. If the factory didn't think it's something you should do, you ought not do it.

I'm interested to see how much better it works. I ran out of daylight before testing it out, but I had a really productive and fun afternoon, since I also built a three point adapter for a two point tiller I picked up a few days ago. Here is a shot from the front:

I need to turn out the front wheels to make it look a little more balanced. I still can't decide if it looks cool, or stupid with the duals on. The ultimate test of that will come in the morning, when SHE takes a look at what has happened to her baby.... Is anyone interested in a Mitsubishi D1800 on turf tires? It's a nice driving little tractor.

Since those pictures have been taken, I've revised the mounts on the little disk

It's copied verbatim, so the audience is slightly different. As reference: A YM2000 is a 20 PTO horsepower 2 wheel drive gray market tractor. The American version is the YM240, different only, in the American version, a 2 speed rather than 3 speed PTO with overrunning clutch, and a reversed throttle linkage.

A couple weeks ago, my girlfriend succumbed to my recent spate of tractor activity, and learned to drive some of my equipment. She really enjoyed it, and has been wanting to grow a "BIIIIIIIIG garden." After she looked some, she now has a YM2000 to do her gardening with! It's all hers, and I'm really proud of her. I think it's kind of redundant, given my plethora of tractors at the moment, but I am NOT going to argue!

The tractor was apparently used at a nursery to pull carts between their rows of plants and do general service/grading type work. It was VERY narrow. A quick test with my smallest disk harrow yielded acceptable results, but it felt really unstable for a new, inexperienced operator, particularly without any ROPS. I wanted to be able to pull my larger disk, though, but it is set up for my larger tractor and is fairly tall on the attachment points for the lower links.

I reversed the rims, and set them out to their widest, which worked much better, but the narrow rice tires combined with the geometry of the disk's 3 point attachment tended to hold the rear end up, and it would easily get stuck, slowly churning holes in the ground, especially when combined with delayed application of the differential lock, and tardy lifting of the implement when the tractor started to slip excessively. (Again, primarily operator inexperience on her part.)

While the correct solution would probably be to replace or revise the attachment points of the disk, and, especially, more thoroughly train the operator, that seemed like a rather boring solution to the problem. I scrounged around a bit, and found some Schedule 80 pipe and 1/4 inch plate. The other addition to this tale is that the girlfriend didn't just get a YM2000. She also ended up with this:

It's a Mitsubishi D1800. (It used to have ag tires on it, but we're getting to that part.) Before all this occurred, I was looking for ag tires or R4 tires for my loader-equipped YM240. I happened to find a set of R4 tires, brand new and never mounted, on (I was told) Kubota rims with a 6 on 6 inch bolt pattern, which won't match my YM240. They do, however, match this Mitsubishi. I had the tire shop swap the R4s for my turf tires on their respective rims, and mounted them up to each tractor. Now I had a spare set of rice tires that were only a tiny bit shorter than those on the girlfriend's YM2000. (Everybody thoroughly confused yet?)

I cut a set of four round plates from the steel plate, and drilled holes to mount to the Mitsubishi pattern wheels in two, and the Yanmar rims in two. Then I cut the tubing, trued it up, and welded them together to get a pair of these:

Sorry for the crummy picture, all I had until this evening was my cell phone for photographs.

After re-reversing the Yanmar wheels to their narrowest setting, I put the spool over the wheel and tightened it up with some longer bolts. Then, I put the Mitsubishi wheels onto the spool, at their widest setting. After it some grunting and a couple trips to the hardware store for fasteners, it looks something like this:

The overall width is just under 64 inches outside to outside. My YM240 (The same tractor) with factory Yanmar turf rims is just under 60 inches. Yanmar originally made this same sort of thing:

(Robbed from California, who cites the optional equipment portion of the operation manual, here:http://www.tractorbynet.com/forums/y...-narrow-2.html)

When it's all said and done, the outer duals sit up from the ground about 3/4 of an inch on pavement, so there is no additional stress on the axle shafts or bearings whatsoever on hard surfaces. In soft terrain, when tire slippage is an issue, the major force they add is forward as tractive effort.

I don't see any major risks to the tractor's longevity or durability, or, especially, safety. In soft ground situations where they only deliver torque, the tractor is operating with no more load than it would in high-traction situations. Even in soft soil, the additional bending moment of the wider wheels must be virtually negligible anyway, and, besides, the tractor was originally engineered to handle dual rear wheels.

This setup will only reduce the force the tractor would see compared to that. Safety wise, the tractor is wider. That makes it less tippy. This setup isn't as stable as it would be if the tires on the outside were in contact with the pavement, but it's not as bad as the wheels at their narrow setting alone.

The failure mode of this apparatus compared to the regular tractor without duals would be to lose the outer wheel(s). The spool is bolted to the hub over the original wheel, so whatever happens, the inner wheel will stay put. Breakage of the inside wheel, or the hub would/will occur, but with no greater likelihood than without the duals, since realistically speaking there is no more force than in the original engineering specification, and, in fact, this design actually would be less than designed for.

Even so, a disclaimer: Please, please, please, nobody look at this project and decide that since some stranger on the internet did this to their tractor it must be a good idea for you to do the same. This has not been engineered beyond literally scratching soapstone onto concrete and mulling in my head. I am a competent weldor, and this will not break my tractor. I have no idea about you, or your abilities or tractor's capabilities. I used what I did because that's what I had. That is not how you should do it. If you need some stranger's advice on how to do something that puts yourself and others in jeopardy, you shouldn't try to do this yourself. If the factory didn't think it's something you should do, you ought not do it.

I'm interested to see how much better it works. I ran out of daylight before testing it out, but I had a really productive and fun afternoon, since I also built a three point adapter for a two point tiller I picked up a few days ago. Here is a shot from the front:

I need to turn out the front wheels to make it look a little more balanced. I still can't decide if it looks cool, or stupid with the duals on. The ultimate test of that will come in the morning, when SHE takes a look at what has happened to her baby.... Is anyone interested in a Mitsubishi D1800 on turf tires? It's a nice driving little tractor.

Since those pictures have been taken, I've revised the mounts on the little disk

I'm sorry the pictures are so big. The other fora I use shrink the photos to a reasonable thumbnail size. I apologize to those with dial-up or slow connections.

steve l

New member

Equipment

2 m9000,9540 all cabgmd700 kuhn 605m vermeer,r23a vermeer rake,468 jd baler,

the reason dual tires are used on tractors is for weight distribution.the outside duals have a very low psi,so when the inside tires start to go down the outside tires hold it up.you would have to use some type of turn buckle to hold the wheels together on that tractor,being that it don't have a rack and pinion axle,in other words the wheels on the outside bolt to axle just like the inside do.the operating manual on my 9540 says"do not use dual wheels under any circumstances".i thinking if you need or put dual wheels on that size tractor,you need a BIGGER tractor.

In reality, the reason for this dual wheel concept on a small tractor is to score a good deal higher on the agricultural coolness scale.

Kytim

Kytim

Kytim, I don't know about the coolness factor...mine looked pretty ridiculous with them on there!

Kidding aside, they did let the tractor pull harder in soft dirt. The tires on this machine are only 9.5 inches wide, so they dig into the soft stuff easily. My implements are within the power range of the tractor, it's just not quite got enough tire on it to pull them, even though the engine will do it. The duals let it work. However, I've pulled them off for most uses, since it made the thing just too cumbersome in comparison. I would be better off to sell the spools and extra tires to someone else who thinks they look cool, and buy a bigger set of tires.

Kidding aside, they did let the tractor pull harder in soft dirt. The tires on this machine are only 9.5 inches wide, so they dig into the soft stuff easily. My implements are within the power range of the tractor, it's just not quite got enough tire on it to pull them, even though the engine will do it. The duals let it work. However, I've pulled them off for most uses, since it made the thing just too cumbersome in comparison. I would be better off to sell the spools and extra tires to someone else who thinks they look cool, and buy a bigger set of tires.

Stability on hills, traction, floation, safety. Depending on your wallet, and your needs, I don't think that duals are a bad thing.What would you possibly have to gain by adding another set of AG's ?

HickoryNut

New member

Equipment

BX25DLB/PForks,Front Blade,3PH,and 3Pt STUFF, BXPanded UA, Piranha, BH Dolly,Rip

I know the book says not to but, has anybody put duals on a L2800, L3400 or a L3700? I like the picture of the front and rear duals. Thanks

gpreuss

New member

Lifetime Member

Equipment

L3200DT w/FEL, K650 Backhoe, 5' Rotary, 40" Howard Rotavator, 6' Rhino blade

I put dualies on my 185 about 30 years ago. Pictures are in my album - click on my user name - I think. LOTS of stability, and LOTS of traction. I'm missing the traction on the new 3200, even with R4s. I never had a problem with the 185's drop axle units.

I needed to add a 1" spacer, reverse the rear wheels, and add a home made 7" spool piece.

Back then I believe it was about a $700 bill to do it. I did it mostly for stability on hills - Made a big difference. L3200 is fine with a couple of 2-1/2" spacers.

I needed to add a 1" spacer, reverse the rear wheels, and add a home made 7" spool piece.

Back then I believe it was about a $700 bill to do it. I did it mostly for stability on hills - Made a big difference. L3200 is fine with a couple of 2-1/2" spacers.