Because I have no clue... Hence my first set of embarrassing noob questions.

This is Little Miss Sunshine, a 1983-vintage four wheel drive who has allegedly done some multiple of 573 hours before joining us on our 12 acres in Sweden a year ago.

Looks like the paintwork is either original (I fondly imagine a genuine 573 hours of gentle work loving cared for by one elderly Japanese farmer), or else she has been through the Vietnamese refurb factory and then stood about in the monsoon for a short while. Either way, she seems to be in reasonable condition and and is a proper little workhorse. This is just as well because as you can see from the state of the buildings in the background, there is lots of work to be done....

However, now that we have done lots of snow-moving and some bush-hogging and some dragging of things about and some lifting, I have ambitions to move beyond just using the three-point and the loader. The thought is to acquire a small trailer or a rear scoop, in order to transport gravel, earth, firewood etc. more efficiently than using the front bucket. Something with hydraulic tipping would be awfully convenient but I know nothing about hydraulics other than it's a way of avoiding manual labour by using pumps and oil. I like the sound of avoiding spadework, sooo...

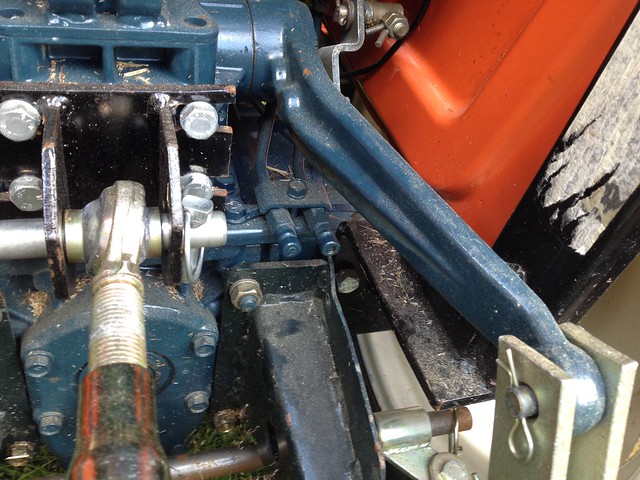

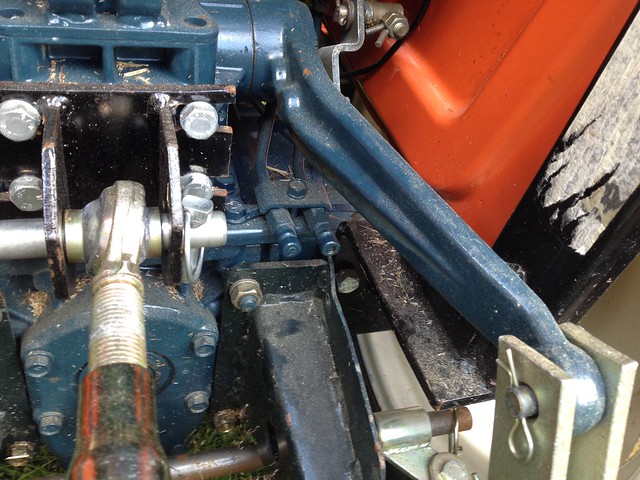

First: What are these two hydraulic outlets/inlets/beasties lurking under the right lift arm, and what can I use them for in the way of making my life easier by buying new toys errrr I mean labour saving implements?

They seem factory-fitted and there is a second lever to the right of the 3-point control lever. This second lever does nothing at the moment, and looks like it might be related to them.

Might these be useable for e.g. a hydraulic tipping trailer? Are they both likely to be 'push'-only, or one 'push' and the other 'return', or are they somehow magically able to both push and return as required? How does one go about hooking up e.g. a tipping trailer so as not to blow up the system by trying to tip it downwards, if you know what I mean?

2: If these are useable, what connector might they be? They look very different to the ones on my neighbour's 50hp Valmet.

According to my vernier, the external diameter is pretty much exactly 1/2 inch (12.35mm, 0.486"). I poked the face of the right one to see if it would move in, and it did, releasing a drop of oil. Internal diameter of the opening is pretty much exactly 1/4 inch (6.175mm, 0.243"). My tentative identification is that they are ISO 16028 HT Series Flushface 1/2", male a.k.a nipple. Does that sound plausible or do grey market Kubotas use some exotic Japanese coupling I need to research? Are there any other distinguishing marks or dimensions to look for?

3: Assuming these are useable for tipping, and I can positively identify them, would I then just order something like these http://www.safewayhyd.com/coupler-adapters.htm to convert the whatever-they-ares to fit whatever connectors are on a hypothetical tipping trailer, tipping gravel scoop, hydraulically adjustable top link or back blade or whatever?

or back blade or whatever?

So - as you can tell, my ignorance of this topic is almost complete. I know how to drive the front loader and make the 3-point go up and down, and I have successfully managed to attach and remove implements, and that's what I know about hydraulics. Where do I go from here if I want to leave my ATV-owning friends pining for the awesomeness of a compact tractor with built-in hydraulics, without making lots of expensive mistakes along the way?

This is Little Miss Sunshine, a 1983-vintage four wheel drive who has allegedly done some multiple of 573 hours before joining us on our 12 acres in Sweden a year ago.

Looks like the paintwork is either original (I fondly imagine a genuine 573 hours of gentle work loving cared for by one elderly Japanese farmer), or else she has been through the Vietnamese refurb factory and then stood about in the monsoon for a short while. Either way, she seems to be in reasonable condition and and is a proper little workhorse. This is just as well because as you can see from the state of the buildings in the background, there is lots of work to be done....

However, now that we have done lots of snow-moving and some bush-hogging and some dragging of things about and some lifting, I have ambitions to move beyond just using the three-point and the loader. The thought is to acquire a small trailer or a rear scoop, in order to transport gravel, earth, firewood etc. more efficiently than using the front bucket. Something with hydraulic tipping would be awfully convenient but I know nothing about hydraulics other than it's a way of avoiding manual labour by using pumps and oil. I like the sound of avoiding spadework, sooo...

First: What are these two hydraulic outlets/inlets/beasties lurking under the right lift arm, and what can I use them for in the way of making my life easier by buying new toys errrr I mean labour saving implements?

They seem factory-fitted and there is a second lever to the right of the 3-point control lever. This second lever does nothing at the moment, and looks like it might be related to them.

Might these be useable for e.g. a hydraulic tipping trailer? Are they both likely to be 'push'-only, or one 'push' and the other 'return', or are they somehow magically able to both push and return as required? How does one go about hooking up e.g. a tipping trailer so as not to blow up the system by trying to tip it downwards, if you know what I mean?

2: If these are useable, what connector might they be? They look very different to the ones on my neighbour's 50hp Valmet.

According to my vernier, the external diameter is pretty much exactly 1/2 inch (12.35mm, 0.486"). I poked the face of the right one to see if it would move in, and it did, releasing a drop of oil. Internal diameter of the opening is pretty much exactly 1/4 inch (6.175mm, 0.243"). My tentative identification is that they are ISO 16028 HT Series Flushface 1/2", male a.k.a nipple. Does that sound plausible or do grey market Kubotas use some exotic Japanese coupling I need to research? Are there any other distinguishing marks or dimensions to look for?

3: Assuming these are useable for tipping, and I can positively identify them, would I then just order something like these http://www.safewayhyd.com/coupler-adapters.htm to convert the whatever-they-ares to fit whatever connectors are on a hypothetical tipping trailer, tipping gravel scoop, hydraulically adjustable top link

So - as you can tell, my ignorance of this topic is almost complete. I know how to drive the front loader and make the 3-point go up and down, and I have successfully managed to attach and remove implements, and that's what I know about hydraulics. Where do I go from here if I want to leave my ATV-owning friends pining for the awesomeness of a compact tractor with built-in hydraulics, without making lots of expensive mistakes along the way?