So I purchased a window motor and a linear actuator for the front-mount snowblower.

That stuff seems pretty straight forward to me.

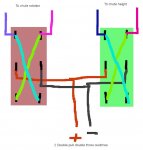

I also purchased 2 DPDT switches (In retrospect I don't see why I couldn't have just used 2 SPCO or SPTT switches.

In any event my brother mentioned the idea of using a joystick. This way I could control both the tilt and chute at the same time.

Has anyone given any thought to this? I'm not really well versed in electrical jargon. What type of joystick would I need? A double pole center off? Some sort of joystick with a potentiometer built in so I can control the speed of the electric motor and actuator?

That stuff seems pretty straight forward to me.

I also purchased 2 DPDT switches (In retrospect I don't see why I couldn't have just used 2 SPCO or SPTT switches.

In any event my brother mentioned the idea of using a joystick. This way I could control both the tilt and chute at the same time.

Has anyone given any thought to this? I'm not really well versed in electrical jargon. What type of joystick would I need? A double pole center off? Some sort of joystick with a potentiometer built in so I can control the speed of the electric motor and actuator?