Not so new here with a couple of B6000's

- Thread starter trevoroni

- Start date

Finally got a chance to start replacing fuel lines tonight.

Started by removing the tank and got up to the inlet of the lift pump.

Hopefully tomorrow I can get the rest done.

I got some clear Tygon lines in the various sizes so I'll be able to determine where air is getting in... hopefully it won't be after this.

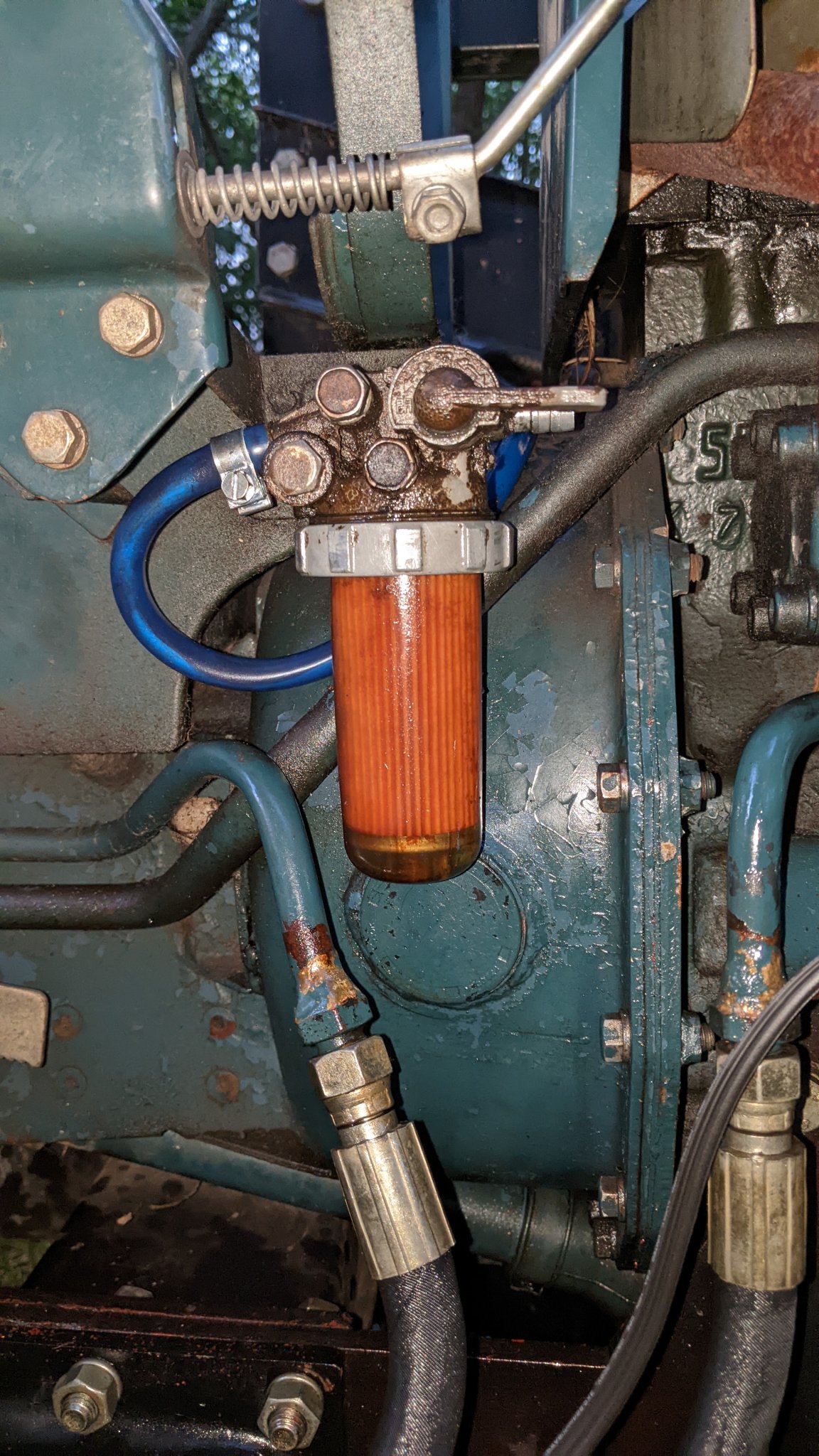

I also picked up a genuine Kubota canister filter as I thought that could be a possible spot where the air could have been getting in.

Started by removing the tank and got up to the inlet of the lift pump.

Hopefully tomorrow I can get the rest done.

I got some clear Tygon lines in the various sizes so I'll be able to determine where air is getting in... hopefully it won't be after this.

I also picked up a genuine Kubota canister filter as I thought that could be a possible spot where the air could have been getting in.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

I was going to suggest replacing lines and checking filter.

Also is there a jet start (bleader valve) on the side of the injection pump?

that could be causing issues.

Another common cause is a bad electric fuel pump.

I your still getting air in the return lines after all that, then you have a bad rebuild on the injectors and they are not sealing ( VERY RARE).

Also is there a jet start (bleader valve) on the side of the injection pump?

that could be causing issues.

Another common cause is a bad electric fuel pump.

I your still getting air in the return lines after all that, then you have a bad rebuild on the injectors and they are not sealing ( VERY RARE).

Thanks Wolfman, glad to hear I'm hopefully on the right path.

Yes there is a bleeder valve on the top side of the injection pump where the fuel line comes in.

I've been loosening it a few turns during my bleeding attempts and it appears like there's a little bit of frothy fuel that comes out each time... even after it's been running for a while.

Yes there is a bleeder valve on the top side of the injection pump where the fuel line comes in.

I've been loosening it a few turns during my bleeding attempts and it appears like there's a little bit of frothy fuel that comes out each time... even after it's been running for a while.

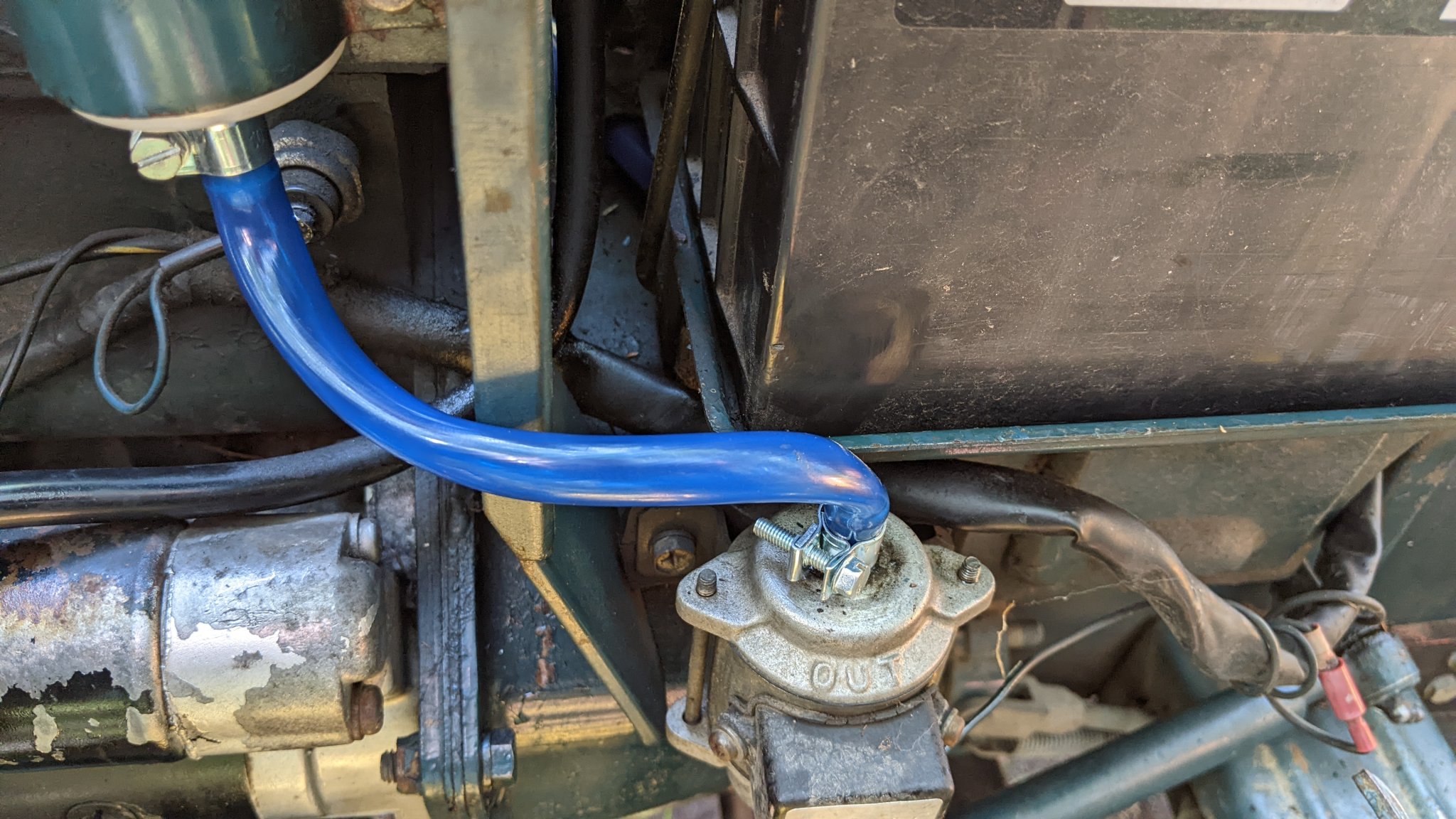

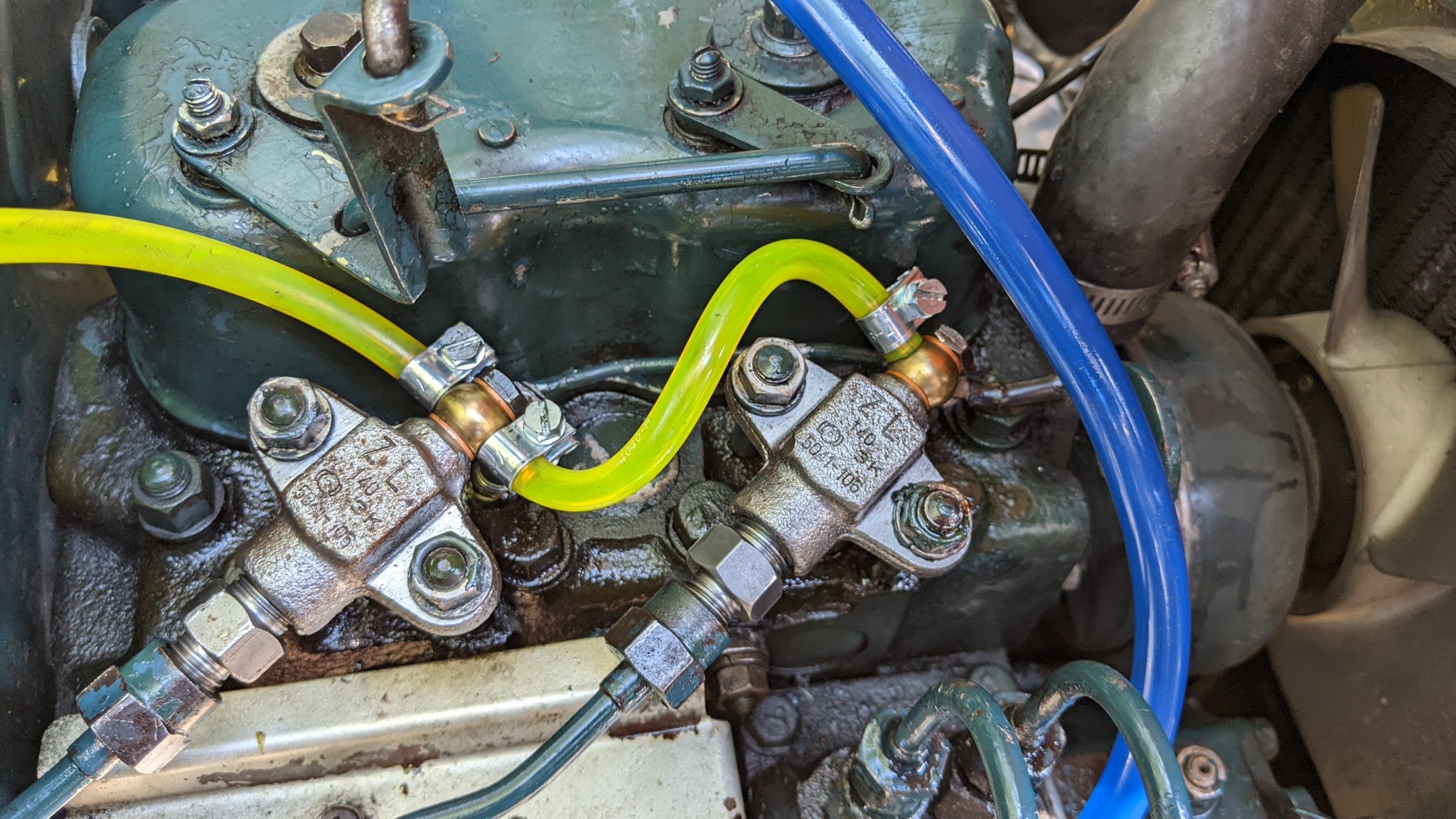

Finished installing the rest of the fuel lines.

I'm pretty happy with how it turned out.

The one line going from the outlet of the lift pump to the filter is a bit short... but I didn't have enough line left to cut another one.

I'm still getting a few bubbles in the return line though... it seemed to get better after the 5 minutes of idling.

I don't see any bubbles in the line up until the injection pump.

I guess next up is see if there's a replacement copper washer available for under the bleed screw as that should be cheap.

I'm pretty confident that the injector shop that did the rebuild did a good job as they've got great reviews and have been in business for over 40 years.

Would something being wrong with the injector pump itself cause air getting in the lines from that point?

I'm pretty happy with how it turned out.

The one line going from the outlet of the lift pump to the filter is a bit short... but I didn't have enough line left to cut another one.

I'm still getting a few bubbles in the return line though... it seemed to get better after the 5 minutes of idling.

I don't see any bubbles in the line up until the injection pump.

I guess next up is see if there's a replacement copper washer available for under the bleed screw as that should be cheap.

I'm pretty confident that the injector shop that did the rebuild did a good job as they've got great reviews and have been in business for over 40 years.

Would something being wrong with the injector pump itself cause air getting in the lines from that point?

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Have you done a compression test on the engine?

As far as air in the return lines, if its starting smoothly that air is very likely not coming from the injection pump as that would vapor lock the injectors and cause them to pop properly.

The bubbles might be a action of the injector getting a little air into the return side when they are closing.

I'm betting it's really not an issue.

As far as air in the return lines, if its starting smoothly that air is very likely not coming from the injection pump as that would vapor lock the injectors and cause them to pop properly.

The bubbles might be a action of the injector getting a little air into the return side when they are closing.

I'm betting it's really not an issue.

Ktrim

Well-known member

Equipment

B2400, lA352 loader,3pth quick hitch/z122r zero turn/restored 52 farmall super a

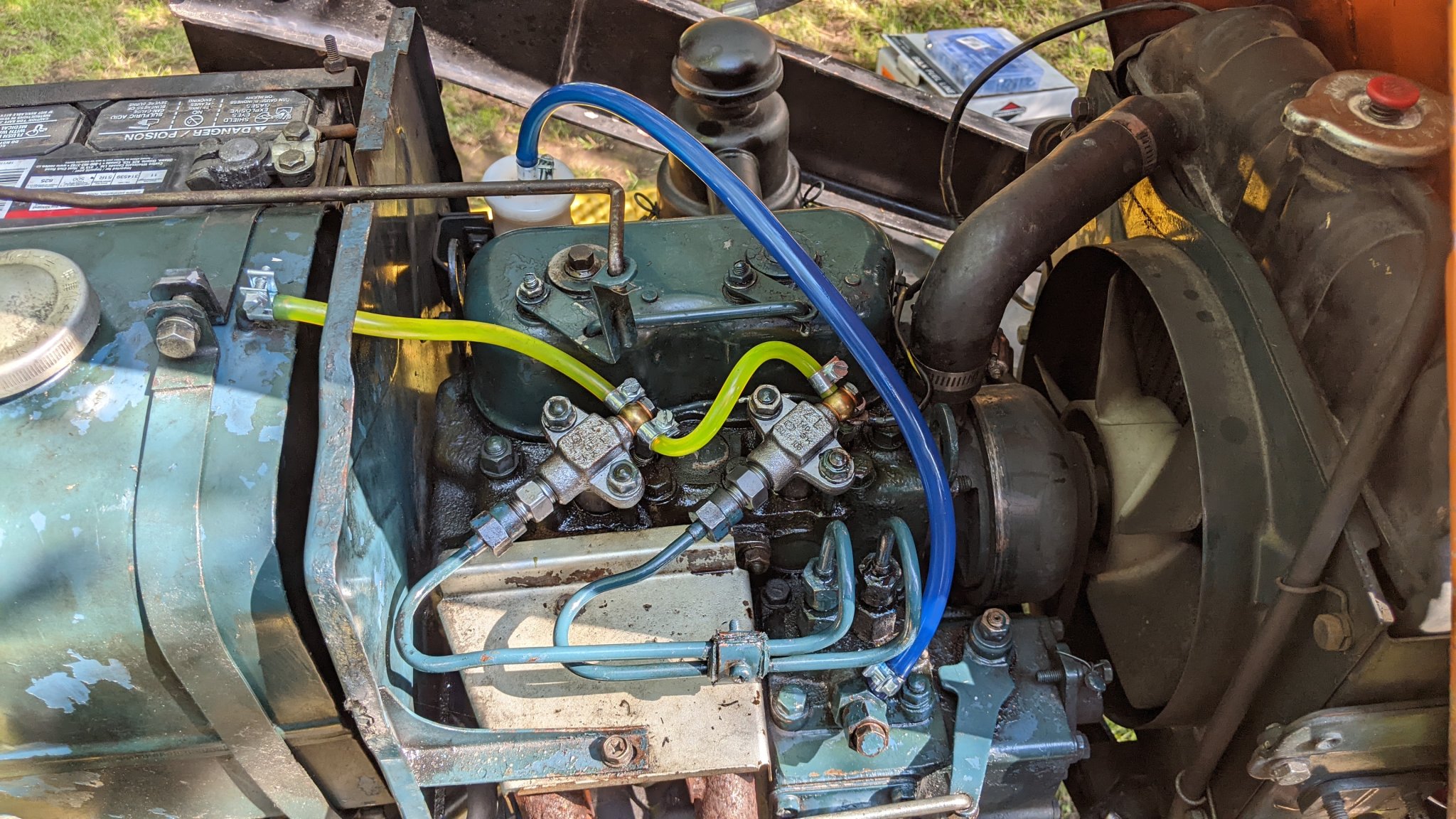

Looks nice and clean in there. That's a plusI adjusted the valves tonight.

They were all between 12-17 thou. Spec is 8-10. I adjusted them all to 9.

I think that was the easiest valve adjustment I've ever done.

Also replaced the fuel hose and clamps going over the valve cover since I had to remove it anyways.

Is there a procedure for adjusting the compression release? I didn't see anything for it in either the operators or service manual. It doesn't seem like it's doing anything now, and the screws are adjusted pretty much flush to the cover on the inside.

View attachment 108487 View attachment 108488 View attachment 108489 View attachment 108490 View attachment 108491

I have not done a compression test yet.Have you done a compression test on the engine?

As far as air in the return lines, if its starting smoothly that air is very likely not coming from the injection pump as that would vapor lock the injectors and cause them to pop properly.

The bubbles might be a action of the injector getting a little air into the return side when they are closing.

I'm betting it's really not an issue.

I know I probably should. I'll have to buy a compression tester for diesel engines I guess.

It is still a little slow to start in my view... but I'm not experienced with these old tractor's. Could be par for the course. It has never failed to start just takes 10-30 seconds of cranking depending on the day.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

How long are you pre heating the glow plugs?I have not done a compression test yet.

I know I probably should. I'll have to buy a compression tester for diesel engines I guess.

It is still a little slow to start in my view... but I'm not experienced with these old tractor's. Could be par for the course. It has never failed to start just takes 10-30 seconds of cranking depending on the day.

The S850 rototiller was missing a few times.

I could have traced one of the old ones into a flat pattern and cut them out with the plasma table at work and formed them...

But these were reasonable priced from White Horse Distribution based out of Winnipeg.

They arrived within 2 days in a fancy box.

I could have traced one of the old ones into a flat pattern and cut them out with the plasma table at work and formed them...

But these were reasonable priced from White Horse Distribution based out of Winnipeg.

They arrived within 2 days in a fancy box.

School for the girls stars next week plus hunting season and winter coming up so I'm guessing things will slow down until the spring.

I did ask my father to keep his eye out for some tire chains a couple weeks ago while he's at the auction/garage sales and he said come with me. After wandering around a few of his sheds we found a few sets that might work or can be trimmed/lengthened to fit.... He must have had 2 dozen sets he's collected over the years.

Hopefully the inline coolant heater will be enough to get it started if it's needed for backup duty during the winter.

I did ask my father to keep his eye out for some tire chains a couple weeks ago while he's at the auction/garage sales and he said come with me. After wandering around a few of his sheds we found a few sets that might work or can be trimmed/lengthened to fit.... He must have had 2 dozen sets he's collected over the years.

Hopefully the inline coolant heater will be enough to get it started if it's needed for backup duty during the winter.

Started it up for the first time since the last post. It started about the same as in the summer, but it was barely below freezing today.

It worked great to clear the pond for skating but didn't have much traction on a slope which is a problem since our driveway is a hill.

I added a wooded weight box with a hundred or so pounds of rocks in it on top of the rototiller that should help.

It worked great to clear the pond for skating but didn't have much traction on a slope which is a problem since our driveway is a hill.

I added a wooded weight box with a hundred or so pounds of rocks in it on top of the rototiller that should help.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

You can get better traction if you add a second set of links between the one's on it now, so make them 2 link chains.

Then if you want even more add cross chains between the links in the middle of the tire (called diamond link chains).

Then if you want even more add cross chains between the links in the middle of the tire (called diamond link chains).

I don't know if it'd help. They were scratching the surface of the frozen snow/gravel but wouldn't bite in.

The weight of the loader even with the rototiller on it puts the center of gravity really far forward. If I jack in the center of the loader arm cross member the rear wheels come off the ground.

If the 4 wheel drive was in better shape it probably wouldn't be a problem but there was a lot of slipping between the ring and pinion gear in the front axle as it clawed it's way up the slope.

The weight of the loader even with the rototiller on it puts the center of gravity really far forward. If I jack in the center of the loader arm cross member the rear wheels come off the ground.

If the 4 wheel drive was in better shape it probably wouldn't be a problem but there was a lot of slipping between the ring and pinion gear in the front axle as it clawed it's way up the slope.

Well I found another B6000 in great shape locally. Funny enough just a few miles from where I got this one.

Everything works like it should and it has the 3pt hitch linkage and a rear blade... With rear hydraulic angle control!

My plan is to move the loader over to it and take the rototiller off mine and sell it for hopefully close to what it cost.

Pic's incoming tomorrow.

Everything works like it should and it has the 3pt hitch linkage and a rear blade... With rear hydraulic angle control!

My plan is to move the loader over to it and take the rototiller off mine and sell it for hopefully close to what it cost.

Pic's incoming tomorrow.

Got it home today!

Now to take off the loader and rototiller from the old one. I'll give them a quick coat of paint before putting them on the new one.

I'll also have to figure out how to Tee the rear hydraulic line and the loader lines together.

I'll also have to decide if I want to swap over the rebuilt injectors and new glow plugs from the old one as well. Same with swapping the OEM air intake over to it or not...

Now to take off the loader and rototiller from the old one. I'll give them a quick coat of paint before putting them on the new one.

I'll also have to figure out how to Tee the rear hydraulic line and the loader lines together.

I'll also have to decide if I want to swap over the rebuilt injectors and new glow plugs from the old one as well. Same with swapping the OEM air intake over to it or not...

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

Thats a very nice install on the remotes - looks factory or professional aftermarket. Does it work independent of the 3pt?Got it home today!

Now to take off the loader and rototiller from the old one. I'll give them a quick coat of paint before putting them on the new one.

I'll also have to figure out how to Tee the rear hydraulic line and the loader lines together.

I'll also have to decide if I want to swap over the rebuilt injectors and new glow plugs from the old one as well. Same with swapping the OEM air intake over to it or not...

View attachment 128137 View attachment 128138 View attachment 128139 View attachment 128140 View attachment 128141 View attachment 128142

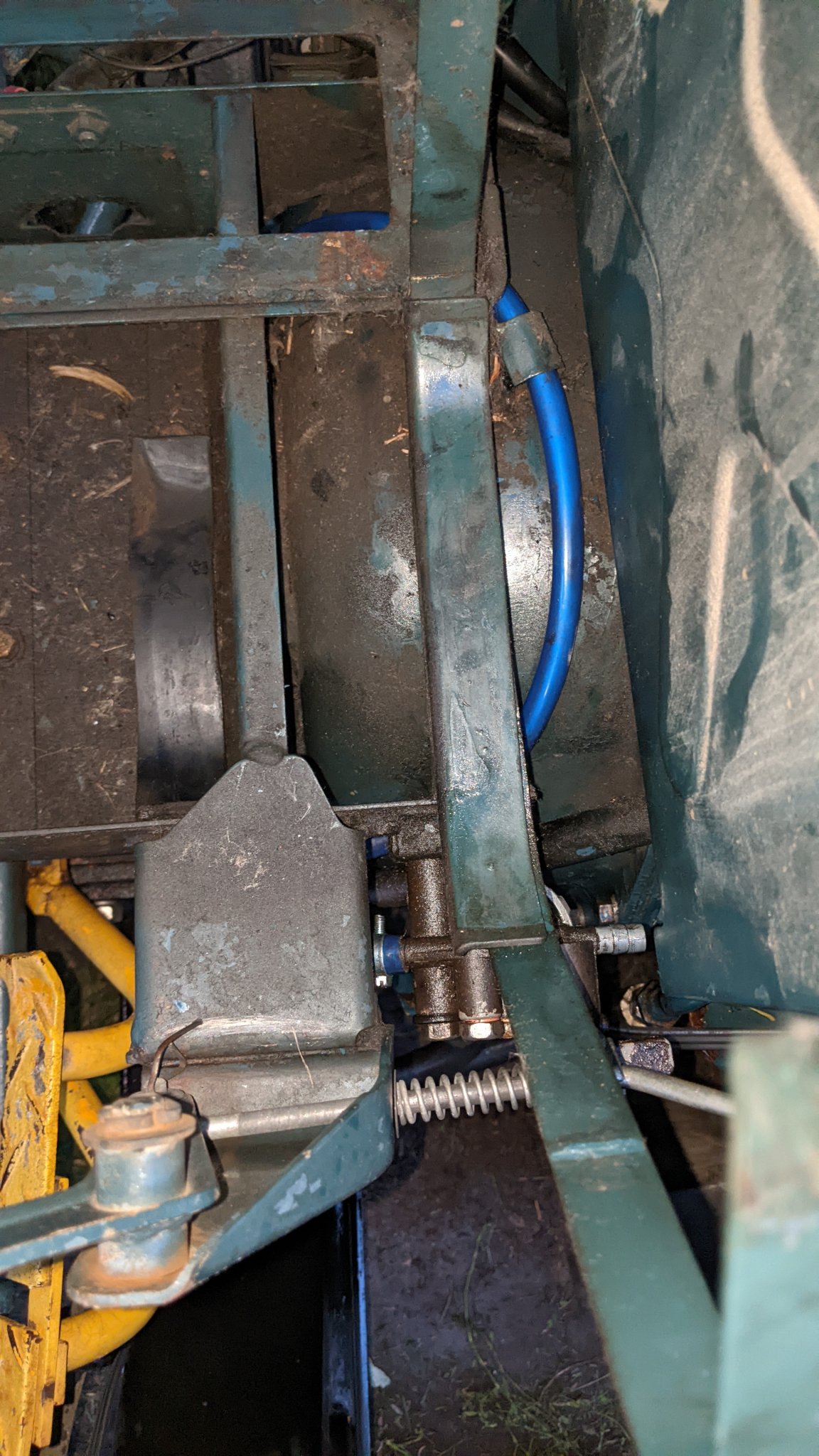

The loader on your old tractor was apparently plumbed into the main hydraulic supply line from the pump. One of the pictures shows what looks like a splice.

Dan