Runs With Scissors

Well-known member

Equipment

L2501 TLB , Grappel, Brush Hog, Box Blade, Ballast box, Forks, Tiller, PH digger

A few weeks ago I ordered some parts from Taylor Freelance for this "Race Gun" that I am playing around with.

Nothing major, just a mag extension, a bigger mag release button and slide rack.

Everything went well except the "slide racker" was hitting the optic before it was seated.

So it was either return them, which would involve postage and packing them up, and then hunting for ones that fit. (They are only 15 bucks)

Or modify them.

I chose the latter.

Here is a pic of the problem. Although it's a bad pic, you can see at the base of the slide racker, a small gap

So I figure if I "trim" a little in the area where the slide racker is hitting the optic, I should be good to go.

So here is my dilemma, I have to figure out how to hold it is the lathe with out scratching it all up.

As you can see its kind of an odd shape ( the photo was an after thought so I snapped a "before' photo of the other one I have.

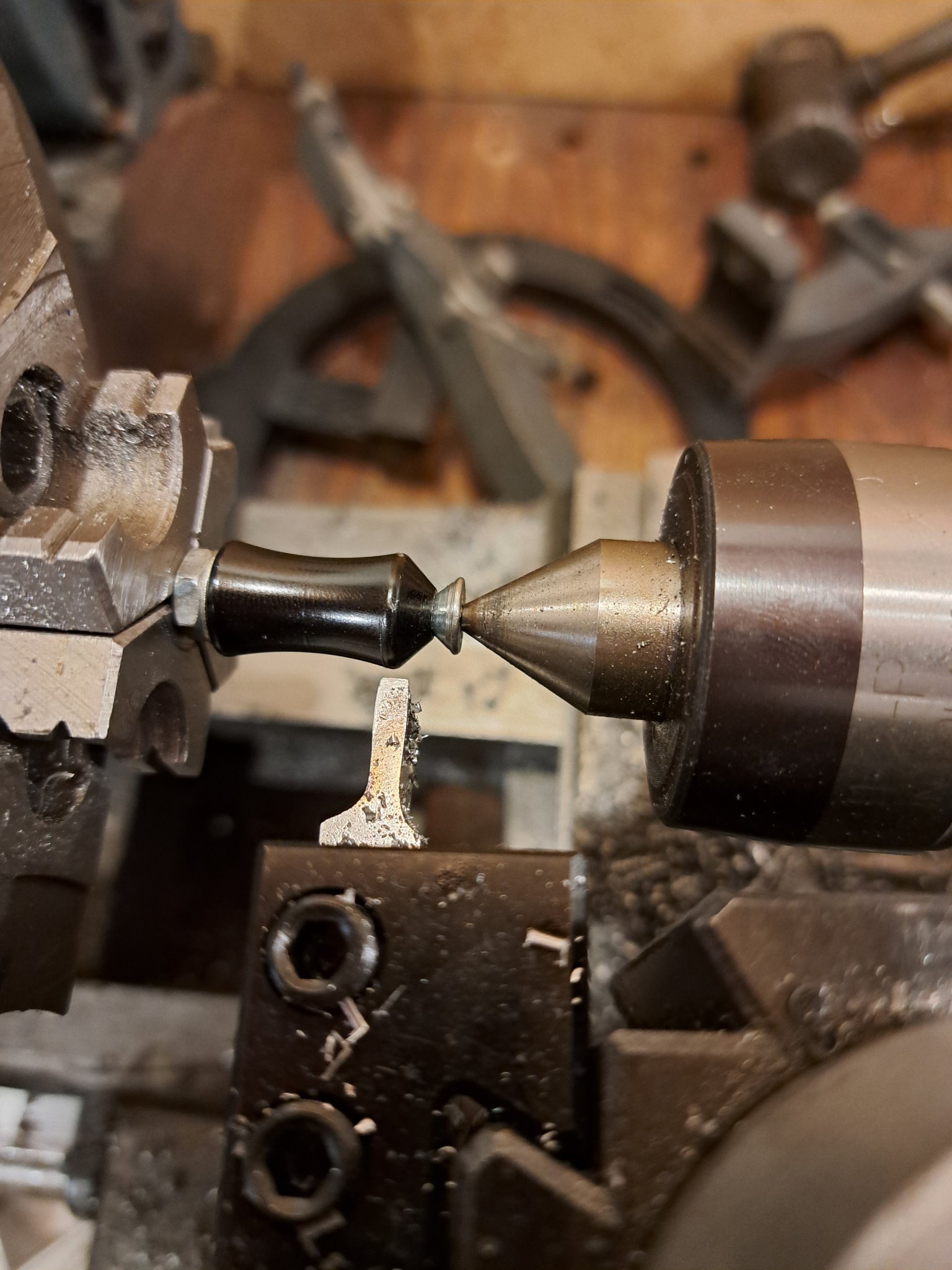

Well after some experimenting I come up with this homemade "mandrel"......(I don't know what else to call it...LOL)

So in my head the taper of the screw should "center" it and I'm hoping the washer will "pull it up tight" so it won't spin.

So after a few goes at it, my "mandrel" keeps coming loose as soon as the bit touches it.

It must be something like "as soon as it touches, it is basically "unscrewing" my mandrel" situation.

Damn......but at least I haven't scratched it .......yet.

Nothing major, just a mag extension, a bigger mag release button and slide rack.

Everything went well except the "slide racker" was hitting the optic before it was seated.

So it was either return them, which would involve postage and packing them up, and then hunting for ones that fit. (They are only 15 bucks)

Or modify them.

I chose the latter.

Here is a pic of the problem. Although it's a bad pic, you can see at the base of the slide racker, a small gap

So I figure if I "trim" a little in the area where the slide racker is hitting the optic, I should be good to go.

So here is my dilemma, I have to figure out how to hold it is the lathe with out scratching it all up.

As you can see its kind of an odd shape ( the photo was an after thought so I snapped a "before' photo of the other one I have.

Well after some experimenting I come up with this homemade "mandrel"......(I don't know what else to call it...LOL)

So in my head the taper of the screw should "center" it and I'm hoping the washer will "pull it up tight" so it won't spin.

So after a few goes at it, my "mandrel" keeps coming loose as soon as the bit touches it.

It must be something like "as soon as it touches, it is basically "unscrewing" my mandrel" situation.

Damn......but at least I haven't scratched it .......yet.