Hello,

We have put the L5450 to its pace in forestry work since I got it last year and its been doiing a great job for us. We basically use it to collect and haul logs with a forwarding trailer. The trailer have its own hydraulic controls and is connected to one of the rear remotes. So to get hydraulic flow to the trailer, we basically jammed the remote in the forward position to activate it. In this position, the motor does not bog down like when the pump is under load and the FEL works normally so we assume the flow goes through the trailer without restriction.

We recently disconnected the trailer and hydraulics to do loader work, but realised that when unplugging the trailer hydraulic, the FEL becomes very slow, as if hydraulic power was used elsewhere. When plugging back the trailer hydraulics, Loader resume to works correctly...

My assumption is that the remote spool valve is not going back to center position correctly and is still trying to send partial flow to the quick connect, causing the loss of power to the loader. I tried to activate the remote in both positions and then to center but the problem is still there when no trailer connected. I guess that the stuck remote in the activated position for a long time is the cause of this...

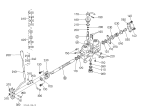

Is my assumption correct? What else could cause the problem if not the remote valve itself? I was thinking to start by replacing the rear spring (040 in 2nd diagram) that seems to put back the spool in center position, does it makes sense?

Thanks a lot helping me fixing this.

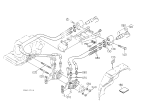

Here are the parts diagrams :

We have put the L5450 to its pace in forestry work since I got it last year and its been doiing a great job for us. We basically use it to collect and haul logs with a forwarding trailer. The trailer have its own hydraulic controls and is connected to one of the rear remotes. So to get hydraulic flow to the trailer, we basically jammed the remote in the forward position to activate it. In this position, the motor does not bog down like when the pump is under load and the FEL works normally so we assume the flow goes through the trailer without restriction.

We recently disconnected the trailer and hydraulics to do loader work, but realised that when unplugging the trailer hydraulic, the FEL becomes very slow, as if hydraulic power was used elsewhere. When plugging back the trailer hydraulics, Loader resume to works correctly...

My assumption is that the remote spool valve is not going back to center position correctly and is still trying to send partial flow to the quick connect, causing the loss of power to the loader. I tried to activate the remote in both positions and then to center but the problem is still there when no trailer connected. I guess that the stuck remote in the activated position for a long time is the cause of this...

Is my assumption correct? What else could cause the problem if not the remote valve itself? I was thinking to start by replacing the rear spring (040 in 2nd diagram) that seems to put back the spool in center position, does it makes sense?

Thanks a lot helping me fixing this.

Here are the parts diagrams :

Attachments

-

486.9 KB Views: 135

-

403.1 KB Views: 143