I am in desperate need of some information, that after hours on the web I can not find.

My dilemma is this, I am restoring a L1500DT, one component of the three point system is totally froze,

it is the Assy. Rod Lift RH (from the parts book).

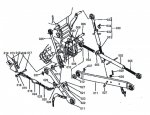

Basically it is the right "adjustable" up-down lift for the three point. (#30 in the picture).

Since I am restoring this I do not want aftermarket parts where possibly.

The cost for the L175 part is $226.34 and the L185 is $77.50

STICKER SHOCK TO SAY THE LEAST

I am hoping some owners out there can provide a good photo

and measurements for both units so I can compare, needless to say

I want to go with the L185 model if it is identical or at least close.

Thanks in advance,

My dilemma is this, I am restoring a L1500DT, one component of the three point system is totally froze,

it is the Assy. Rod Lift RH (from the parts book).

Basically it is the right "adjustable" up-down lift for the three point. (#30 in the picture).

Since I am restoring this I do not want aftermarket parts where possibly.

The cost for the L175 part is $226.34 and the L185 is $77.50

STICKER SHOCK TO SAY THE LEAST

I am hoping some owners out there can provide a good photo

and measurements for both units so I can compare, needless to say

I want to go with the L185 model if it is identical or at least close.

Thanks in advance,

Attachments

-

85 KB Views: 318