I have a SVL90-2 that I recently purchased. After running for 15 - 20 minutes at full throttle it threw a code E:9206. That code means exhaust temperature sensor (DOC Outlet). I contacted several dealers and was informed that this was likely due to a faulty sensor or wiring issue. From what i could see the wiring had been tampered with before so it appears that the previous owner had an issue too. I checked the wires going to the first sensor before the DPF filter back to where they meet up with the big harness and couldn't find anything out of order, so I went ahead and ordered a new sensor. Well I installed it today and now I get two codes. Also to complicate things the machine says it needs to regen and it tries but never completes. about 15 minutes into the regen i get the E:9206 code and at the same time I get code E:9002 which according to the manual means DPF is regenerated. All while these codes are displaying on the panel the machine is trying to regen and the yellow regen indicator is flashing. I tried to pause the regen to see if it would change anything and i get a red warning symbol on the dash and a new code E:9006 which is Requirement for DPF regeneration. Needless to say I am a bit puzzled. Is there any way a consumer can clear the codes from the ECM? anyone run into anything similar to this? thanks in advance for any help!

Kubota SVL90-2 DPF/REGEN Problem

- Thread starter JRether

- Start date

As far as I know you are dependent on a dealer to bring a laptop out to read and clear any and all codes (or haul the machine in.) Do you have the shop manual? On some of the tractors you can do a little bit of resetting through the Intellipanel, but nothing of the sort of errors you are mentioning. If you can't get it to do a regen, better not to run it. Sorry to hear your new machine was not up to snuff when you got it.

On my L3901, if the yellow regen light is flashing it hasn't started to do the regen and it normally needs the RPMs increased to get the DPF hot enough to do the regen. It isn't doing the regen till the yellow light goes solid. Is there a light that indicates to increase RPMs?

I did some searching on the Internet and found the Operation Manual for your skid steer. Here are the directions for doing a regen:

During DPF regeneration cycle keep clear of the

surrounding environment in mind. Do not allow the

ambient temperature to rise excessively due to heat

from the regeneration. If such occurs, activate the

inhibit switch.

The DPF regeneration cycle only starts in the following

conditions. If any of the conditions are not met, the

DPF regeneration cycle may be interrupted.

(1) Coolant temperature above 65 C

(2) DPF temperature above 250 C

(3) Engine rpm above 1200 rpm

The regeneration usually takes about 15-20 minutes.

It depends, however, on the outside air temperature,

exhaust gas temperature and filter PM level.

Do not attempt to interrupt the DPF regeneration cycle

unnecessarily.

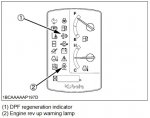

And here is a picture on the indicators:

So when the regen light starts flashing you need to raise the RPMs at least to 1200, if the Engine rev up warning is flashing still, you need to raise the RPMs till it stops. The regen light should change to solid on when the coolant and DPF temperatures are met.

Hope this helps. Let us know the outcome.

During DPF regeneration cycle keep clear of the

surrounding environment in mind. Do not allow the

ambient temperature to rise excessively due to heat

from the regeneration. If such occurs, activate the

inhibit switch.

The DPF regeneration cycle only starts in the following

conditions. If any of the conditions are not met, the

DPF regeneration cycle may be interrupted.

(1) Coolant temperature above 65 C

(2) DPF temperature above 250 C

(3) Engine rpm above 1200 rpm

The regeneration usually takes about 15-20 minutes.

It depends, however, on the outside air temperature,

exhaust gas temperature and filter PM level.

Do not attempt to interrupt the DPF regeneration cycle

unnecessarily.

And here is a picture on the indicators:

So when the regen light starts flashing you need to raise the RPMs at least to 1200, if the Engine rev up warning is flashing still, you need to raise the RPMs till it stops. The regen light should change to solid on when the coolant and DPF temperatures are met.

Hope this helps. Let us know the outcome.

Attachments

-

32.6 KB Views: 54,786

Yeah you really need diag master in order to see what those sensors are seeing. If they're not seeing any signal at all, it's possible that there's a wiring problem. If they see any sort of signal but the ECU's not responding to them, then it's possible to have a faulty ECU, faulty sensor, etc. OR another possibility, perhaps the sensors and wiring are fine but the PO could have sold you a SVL with a "DIY cleaned" DPF-which will also give issues similar to what your'e seeing. Been through this and it can (will?) be a nightmare if diag-master is not used in conjunction with a thorough understanding of how the systems work.

All that applies to any DPF tractor, kubota's proprietary diag-master software and hardware is required for proper diagnosis and repair.

I mentioned the DIY DPF cleaning because some have tried this and they said it was "successful"....in quotes because you don't know if the substrate was damaged and/or if it was actually cleaned. Too many unknowns. I've heard of folks doing this and what they don't realize is that there's more to it than just cleaning it...and again, diag-master is required to re-set everything, or the systems won't work right and on one occasion, resulted in a holed piston on an MX5800. That was a very expensive lesson learned for the owner.

All that applies to any DPF tractor, kubota's proprietary diag-master software and hardware is required for proper diagnosis and repair.

I mentioned the DIY DPF cleaning because some have tried this and they said it was "successful"....in quotes because you don't know if the substrate was damaged and/or if it was actually cleaned. Too many unknowns. I've heard of folks doing this and what they don't realize is that there's more to it than just cleaning it...and again, diag-master is required to re-set everything, or the systems won't work right and on one occasion, resulted in a holed piston on an MX5800. That was a very expensive lesson learned for the owner.

We have seen problems with the DPF temp senders caused by the insulation sleeve around the wiring wearing through the wires and causing a partial short. this only happened on the first ones because kubota caught it and changed the way the insulation was taped to the wires thus preventing the chafing . this was on the machine side of the disconnect plug and affected all three of the sensors.Yeah you really need diag master in order to see what those sensors are seeing. If they're not seeing any signal at all, it's possible that there's a wiring problem. If they see any sort of signal but the ECU's not responding to them, then it's possible to have a faulty ECU, faulty sensor, etc. OR another possibility, perhaps the sensors and wiring are fine but the PO could have sold you a SVL with a "DIY cleaned" DPF-which will also give issues similar to what your'e seeing. Been through this and it can (will?) be a nightmare if diag-master is not used in conjunction with a thorough understanding of how the systems work.

All that applies to any DPF tractor, kubota's proprietary diag-master software and hardware is required for proper diagnosis and repair.

I mentioned the DIY DPF cleaning because some have tried this and they said it was "successful"....in quotes because you don't know if the substrate was damaged and/or if it was actually cleaned. Too many unknowns. I've heard of folks doing this and what they don't realize is that there's more to it than just cleaning it...and again, diag-master is required to re-set everything, or the systems won't work right and on one occasion, resulted in a holed piston on an MX5800. That was a very expensive lesson learned for the owner.