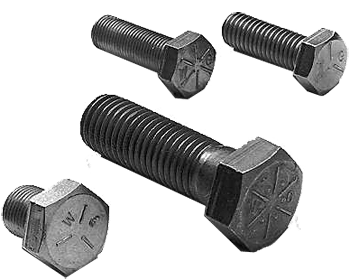

There are a lot of general purpose bolts on every Kubota tractor, but I cannot find much information on them. There are no grade markings on many of them that make any sense. For example, on my B7200, there are a lot of M10x1.25 bolts holding controls, accessory mounting brackets, etc. on. Most of these have a "7" stamped on top. There are also M8x1.25 bolts that have a "4" stamped on them. You can look any of these bolts up on a Kubota parts diagram, and it will reveal the Kubota part number, but no other information, not even size in many cases. The torque tables in the manuals cover critical fasteners like rod and main bolts, but I can't find any torquing info on standard bolts.

The reason I ask is that I'm a bit obsessive about torque specs, even on general purpose fasteners. Since I can't really be sure what grade a lot of these fasteners are, I don't know what I can safely torque them to.

Does anyone know anything about Kubota Standard Bolt Grades and Torque values. Should I just assume they're grade 8.8 and take my chances?

The reason I ask is that I'm a bit obsessive about torque specs, even on general purpose fasteners. Since I can't really be sure what grade a lot of these fasteners are, I don't know what I can safely torque them to.

Does anyone know anything about Kubota Standard Bolt Grades and Torque values. Should I just assume they're grade 8.8 and take my chances?