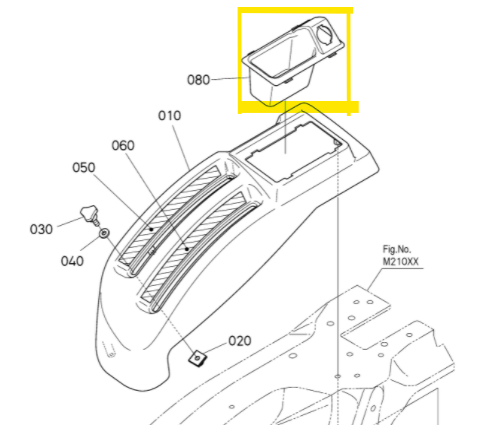

Has anyone done a 3D printing of something to fit inside this 'holder'?

My thought is to either 3D print something to fill in the gaps of an existing NiLight switch box (I have one that fits inside but is loose) or else custom print one. My biggest unknown is how to get the measurements right for some of the curves inside of the holder.

I have access to CAD programs and 3D printers (my company has a couple that employees are allowed to use) but the actual measuring I'm unfamiliar with.

Of course if someone has already done the work that'd be even cooler =)

My thought is to either 3D print something to fill in the gaps of an existing NiLight switch box (I have one that fits inside but is loose) or else custom print one. My biggest unknown is how to get the measurements right for some of the curves inside of the holder.

I have access to CAD programs and 3D printers (my company has a couple that employees are allowed to use) but the actual measuring I'm unfamiliar with.

Of course if someone has already done the work that'd be even cooler =)