Hello,

in the other two threads I already discussed my saga of the not well starting D1005.

Once the engine runs, it runs nicely but starting is very hard.

Since my last post I had the injectors and injector pump checked and resealed by a professional.

I checked the compression and on cylinder 1 and 2 I get good compression( around 190 psi ) while on the third I only get 50 ( with oil much better, so I guess the rings or the cylinder wall are having issues )

I guess this issue does also affect the cold start quite a bit.

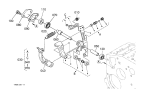

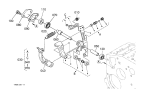

Now after installing the new injectors and the serviced pump I did not get any start at all and I decided to play with the "Fuel Limitation Bolt" and the "idle apparatus" screw.

At some point I got the engine to start and run but soon noticed that there is a very fine line between the engine not responding to throttle and the engine "running away".

In the workshop manual I could not find any systematical procedure how to set the idle apparatus and fuel limitation bolt.

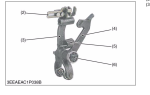

From the manual I do understand that the latter is used to decrease fuel but how does the idle apparatus work exactly? From looking at the inside of this part, it seems to be acting on the "Slide Plate" ( 2 ) this limiting also the shut off somewhat?

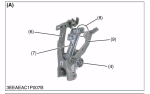

My other concern is the "torque pin" (8):

the desription says:

"When the engine is running, the fork lever 2 (9) and

the floating lever (7) are moving with the fork lever 1 (6)

due to the tension of the governor spring (3).

During the time, the torque pin (8) is pressed into the

floating lever by centrifugal force of the governor weight(5)."

I wonder what effect a failure in that pin assembly would have?

There seems to be a spring in that assembly (A) which could be faulty.

However I am reluctant to play with things here before I know how to put it back properly.

Seems I could reach the screw from the stop solenoid opening.

If anyone has any idea on how I could proceed to find the issues, please shoot!

Thanks so much. I already learned quite a bit with the help of this wonderful forum!

in the other two threads I already discussed my saga of the not well starting D1005.

Once the engine runs, it runs nicely but starting is very hard.

Since my last post I had the injectors and injector pump checked and resealed by a professional.

I checked the compression and on cylinder 1 and 2 I get good compression( around 190 psi ) while on the third I only get 50 ( with oil much better, so I guess the rings or the cylinder wall are having issues )

I guess this issue does also affect the cold start quite a bit.

Now after installing the new injectors and the serviced pump I did not get any start at all and I decided to play with the "Fuel Limitation Bolt" and the "idle apparatus" screw.

At some point I got the engine to start and run but soon noticed that there is a very fine line between the engine not responding to throttle and the engine "running away".

In the workshop manual I could not find any systematical procedure how to set the idle apparatus and fuel limitation bolt.

From the manual I do understand that the latter is used to decrease fuel but how does the idle apparatus work exactly? From looking at the inside of this part, it seems to be acting on the "Slide Plate" ( 2 ) this limiting also the shut off somewhat?

My other concern is the "torque pin" (8):

the desription says:

"When the engine is running, the fork lever 2 (9) and

the floating lever (7) are moving with the fork lever 1 (6)

due to the tension of the governor spring (3).

During the time, the torque pin (8) is pressed into the

floating lever by centrifugal force of the governor weight(5)."

I wonder what effect a failure in that pin assembly would have?

There seems to be a spring in that assembly (A) which could be faulty.

However I am reluctant to play with things here before I know how to put it back properly.

Seems I could reach the screw from the stop solenoid opening.

If anyone has any idea on how I could proceed to find the issues, please shoot!

Thanks so much. I already learned quite a bit with the help of this wonderful forum!