Buyer Beware of Mower King/AGT CompactorSSVR72: www.AGROTKINDUSTRIAL.com

Note: After 6 months of knowing of this problem, the manufacture has still not changed the design of the compactors. In fact, they have no plan to change the design to cure these problems.

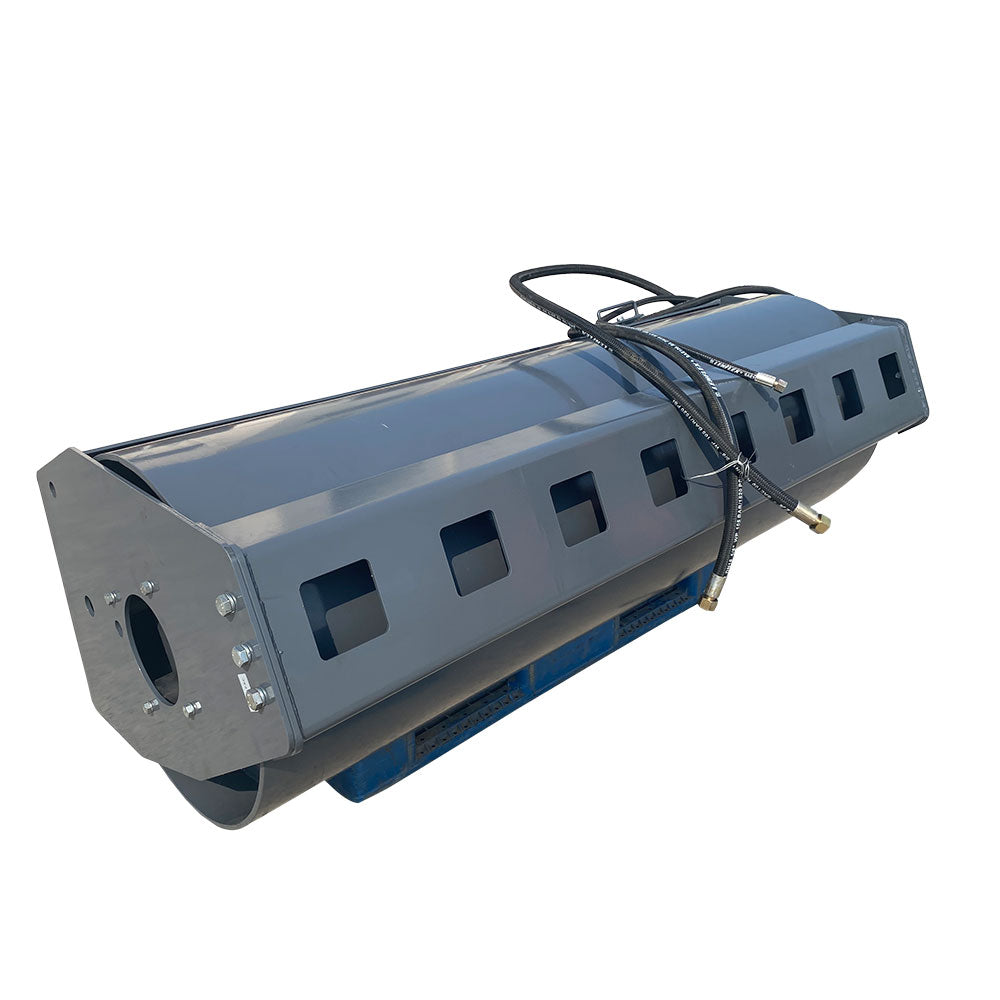

2/1/23 I purchased a Mower King (AGT) smooth roller compactor. I needed a compactor to complete a job next week. No compactors were available for rent for over a month out. The only compactor I could find was a high flow Mower King unit. The unit was new and still in the steel crate and cost $4,500.00. The unit was located 2 hours away. When I got it home I discovered a multitude of issues with the unit.

2/6/23: Update. I discovered that Mower King/AGT does NOT give any type of warrantee with any of their products unless you directly purchase their products from their warehouse in Chicago. Therefore, if you purchase a new product from MK/AGT and it breaks the first time you use it, they will not stand behind their product. This kind of tells you how confident they are in their quality.

1) The compactor will NOT connect/couple to a Kubota equipped with an auto hydraulic locking system. How could engineers be this absent minded? The compactors roller pivot hub extends into the skid steers attachment plate. It extends so far that it contacts heavily with the hydraulic cylinder for the auto coupling system. The compactor pivot hub is approximately 3/4 inches too long, and could not be cut shorter. To fix this, I had to purchase an additional 3/8 thick attachment mounting plate ($276.00). I then had to plasma cut a hole in the new plate so I could later access the HDLPE bushing on the pivot shaft. (See picture b below). I then welded the additional attachment mounting plate to the mounting plate that was already welded to the compactor by the factory,. This was done by adding 2- 3" x 3/8" x 16" steel plates on the side and 1-1-1/4"x3/8"x 36" steel plate on the top of the two attachment plates thus joining the two attachment plates together. What a disaster!

2) The unit did not come with quick connect couplers. A set of quick connect couplers (Male, Female and bypass couplers) cost $710.00.

3) The hose ends were some type of metric female threaded ends. They were not compatible with standard Skid Steer DIN quick connect couplers. The Hydraulic shop could not find an adaptor fitting in the GATES fitting book that would fit the metric hose ends. They had to cut off all three female hose ends off the hoses that were supplied by the manufacture and switched to DIN fittings ($50.00).

4) Even though there is a hose loom that is well built and mounted to the machine, when the hoses are fed through the loom and connected to the SS, all three hoses rub on the compactor drum. I had the make two new taller hose looms to prevent rubbing.

Update 2/4/23: Additional problems.

5) I discovered that the unit was assembled with the hydraulic motor clocked in the wrong position but, even though I corrected the clock of the hydraulic motor to the specified clock, the hoses are still rubbing the roller. Had to design a higher mounting bracket.

6) I used the compactor for the first time. Within one minute the bearing the motor side was smoking. I shut it off imeadately. Discovered that the compactor was not greased from the factory. All bearings were dry.

7) The primary hydraulic motor bearing grease fitting was not accessible and the zerk fitting was missing. It was impossible to access fitting and install the zerk fitting. An access hole was near buy, but was 2" away from the zerk fitting position (again poor design). I had to drill a 5/8 hole in the side frame in order to install the zerk and grease the bearing.

8) Zerk fitting was missing from the center shaft of the left side. Replaced and greased bearing.

8) The large self aligning bearing on the opposite side of the hydraulic motor was clocked in the wrong position. I had to remove the 4-10mm bolts and clock the bearing so the the zerk fitting was facing the down position.

Update: 2/6/23. Today I used the compactor for the first time. It ran for approximately 30 minutes. At that point the motor side began smoking very bad. I shut it off and greases the bearing again. It lasted another 5 minutes and then locked up solid. Upon disassembly, I discovered that the bearings ($1000.00) heated up and were destroyed. In addition, the Style #4 dampener for the motor broke in to three pieces and broke bolts. Very aggravating. And to top it off the manufacture does not provide any type of warrantee, unless you purchase directly from their warehouse. I'll let ya'll know the cost of parts.

UPDATE 3/7/23. Last week (3 months later), the remainder of the parts arrived and I reassembled the the compactor. Some things I discovered:

The simple root cause was that my compactor bearings failing was because it was not greased from the factory. The first time the compactor began smoking from too much bearing heat, I shut it down and greased it. I tend. to over grease everything. I put approximately 25 pumps of grease on both sided of the compactor ZERK fittings. While repairing the unit, I discovered that 25 pumps of grease was just barley enough to suffice the grease needed on the non-motor side. I had to pump 33 pumps of grease in the grease fitting that's is located on in the end of the shaft in order for the large internal bearing to be greased fully. The motor side bearing cavity took 50 pumps of grease, which is a little over 1/2 a large tube of grease (90 Pumps of grease consumes a full tube of grease). My motto is, grease a lot and grease often, ya can never have too much grease. I also took pictures of how I clocked the hydraulic motor and ran the hoses. I had to make the hose retainer (circled in Purple) with the spring in order to keep the hoses from rubbing.

Side Note: Remember to not let your hydraulic hosed rub on any parts of the compactor. When the compactor is on, if hoses are rubbing against the compactor, you could rub a hole on a hose within a couple of minutes.

Conclusion: I have purchased China implements for skid steers and excavators in the past and they were made very well and withstood a beating. I believe that Mower King has completely dropped the ball on this compactor. I also discovered that this design of compactor is sold by many china companies who claim that he manufacture the unit, but they don't. I would have taken the compactor back to who I purchased it from but, it has rained here a lot and has delayed one of my jobs for over three months. I have to think about customer service.

I’m very disappointed in Mower Kings engineering department and its management, I sent an email to them, I can’t wait to find out how customer service is managed. No one followed through with testing to see if the product was well designed. Corners were cut to cut cost and improve profits without having the end user in mind. Clearly their engineering team lack proper protocols to check their designs.

Mower King/AGT acknowledged that there are design flaws with this unit. They did not explain what the design flaws were. They minimized they mistake even though they clearly knew the compactor had a major design flaw. MowerKing/AGT then decided to maintain the current path of poor business acumen and leave the compactors on the market. Bottom line, this clearly tells everyone what type of service you will get for Mower King

There is no call or reason for this type of poor workmanship from any company, and then not own a recall.

If you have any questions or would like pictures not see how I correct these poor designs, feel free to call me: Three Oaks Property Management, Florence, Alabama

Note: After 6 months of knowing of this problem, the manufacture has still not changed the design of the compactors. In fact, they have no plan to change the design to cure these problems.

2/1/23 I purchased a Mower King (AGT) smooth roller compactor. I needed a compactor to complete a job next week. No compactors were available for rent for over a month out. The only compactor I could find was a high flow Mower King unit. The unit was new and still in the steel crate and cost $4,500.00. The unit was located 2 hours away. When I got it home I discovered a multitude of issues with the unit.

2/6/23: Update. I discovered that Mower King/AGT does NOT give any type of warrantee with any of their products unless you directly purchase their products from their warehouse in Chicago. Therefore, if you purchase a new product from MK/AGT and it breaks the first time you use it, they will not stand behind their product. This kind of tells you how confident they are in their quality.

1) The compactor will NOT connect/couple to a Kubota equipped with an auto hydraulic locking system. How could engineers be this absent minded? The compactors roller pivot hub extends into the skid steers attachment plate. It extends so far that it contacts heavily with the hydraulic cylinder for the auto coupling system. The compactor pivot hub is approximately 3/4 inches too long, and could not be cut shorter. To fix this, I had to purchase an additional 3/8 thick attachment mounting plate ($276.00). I then had to plasma cut a hole in the new plate so I could later access the HDLPE bushing on the pivot shaft. (See picture b below). I then welded the additional attachment mounting plate to the mounting plate that was already welded to the compactor by the factory,. This was done by adding 2- 3" x 3/8" x 16" steel plates on the side and 1-1-1/4"x3/8"x 36" steel plate on the top of the two attachment plates thus joining the two attachment plates together. What a disaster!

2) The unit did not come with quick connect couplers. A set of quick connect couplers (Male, Female and bypass couplers) cost $710.00.

3) The hose ends were some type of metric female threaded ends. They were not compatible with standard Skid Steer DIN quick connect couplers. The Hydraulic shop could not find an adaptor fitting in the GATES fitting book that would fit the metric hose ends. They had to cut off all three female hose ends off the hoses that were supplied by the manufacture and switched to DIN fittings ($50.00).

4) Even though there is a hose loom that is well built and mounted to the machine, when the hoses are fed through the loom and connected to the SS, all three hoses rub on the compactor drum. I had the make two new taller hose looms to prevent rubbing.

Update 2/4/23: Additional problems.

5) I discovered that the unit was assembled with the hydraulic motor clocked in the wrong position but, even though I corrected the clock of the hydraulic motor to the specified clock, the hoses are still rubbing the roller. Had to design a higher mounting bracket.

6) I used the compactor for the first time. Within one minute the bearing the motor side was smoking. I shut it off imeadately. Discovered that the compactor was not greased from the factory. All bearings were dry.

7) The primary hydraulic motor bearing grease fitting was not accessible and the zerk fitting was missing. It was impossible to access fitting and install the zerk fitting. An access hole was near buy, but was 2" away from the zerk fitting position (again poor design). I had to drill a 5/8 hole in the side frame in order to install the zerk and grease the bearing.

8) Zerk fitting was missing from the center shaft of the left side. Replaced and greased bearing.

8) The large self aligning bearing on the opposite side of the hydraulic motor was clocked in the wrong position. I had to remove the 4-10mm bolts and clock the bearing so the the zerk fitting was facing the down position.

Update: 2/6/23. Today I used the compactor for the first time. It ran for approximately 30 minutes. At that point the motor side began smoking very bad. I shut it off and greases the bearing again. It lasted another 5 minutes and then locked up solid. Upon disassembly, I discovered that the bearings ($1000.00) heated up and were destroyed. In addition, the Style #4 dampener for the motor broke in to three pieces and broke bolts. Very aggravating. And to top it off the manufacture does not provide any type of warrantee, unless you purchase directly from their warehouse. I'll let ya'll know the cost of parts.

UPDATE 3/7/23. Last week (3 months later), the remainder of the parts arrived and I reassembled the the compactor. Some things I discovered:

The simple root cause was that my compactor bearings failing was because it was not greased from the factory. The first time the compactor began smoking from too much bearing heat, I shut it down and greased it. I tend. to over grease everything. I put approximately 25 pumps of grease on both sided of the compactor ZERK fittings. While repairing the unit, I discovered that 25 pumps of grease was just barley enough to suffice the grease needed on the non-motor side. I had to pump 33 pumps of grease in the grease fitting that's is located on in the end of the shaft in order for the large internal bearing to be greased fully. The motor side bearing cavity took 50 pumps of grease, which is a little over 1/2 a large tube of grease (90 Pumps of grease consumes a full tube of grease). My motto is, grease a lot and grease often, ya can never have too much grease. I also took pictures of how I clocked the hydraulic motor and ran the hoses. I had to make the hose retainer (circled in Purple) with the spring in order to keep the hoses from rubbing.

Side Note: Remember to not let your hydraulic hosed rub on any parts of the compactor. When the compactor is on, if hoses are rubbing against the compactor, you could rub a hole on a hose within a couple of minutes.

Conclusion: I have purchased China implements for skid steers and excavators in the past and they were made very well and withstood a beating. I believe that Mower King has completely dropped the ball on this compactor. I also discovered that this design of compactor is sold by many china companies who claim that he manufacture the unit, but they don't. I would have taken the compactor back to who I purchased it from but, it has rained here a lot and has delayed one of my jobs for over three months. I have to think about customer service.

I’m very disappointed in Mower Kings engineering department and its management, I sent an email to them, I can’t wait to find out how customer service is managed. No one followed through with testing to see if the product was well designed. Corners were cut to cut cost and improve profits without having the end user in mind. Clearly their engineering team lack proper protocols to check their designs.

Mower King/AGT acknowledged that there are design flaws with this unit. They did not explain what the design flaws were. They minimized they mistake even though they clearly knew the compactor had a major design flaw. MowerKing/AGT then decided to maintain the current path of poor business acumen and leave the compactors on the market. Bottom line, this clearly tells everyone what type of service you will get for Mower King

There is no call or reason for this type of poor workmanship from any company, and then not own a recall.

If you have any questions or would like pictures not see how I correct these poor designs, feel free to call me: Three Oaks Property Management, Florence, Alabama

Last edited: