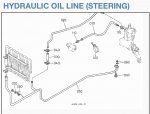

I’ve developed a leak in the steering line that drips too fast to be usable. I thought it was the rear of the propeller shaft but upon closer inspection it is the O-ring in the steering hydraulic line where it mounts into the bottom of the pump near the rear of the tractor. I have tried every O-ring size imaginable that fits and it still leaks. The parts diagram shows two O-rings one on top of the other I’ve never seen this before Is this normal. I’ve tried 1, 2 and, 3 O-rings. Depending on the size of the O-ring the amount of leakage changes but never stops has anyone ever ran into this issue or have any advice. I have attached photos of the line in question.

thank you

thank you

Attachments

-

342.1 KB Views: 151

-

342.2 KB Views: 159

-

278.9 KB Views: 162

-

93.2 KB Views: 158