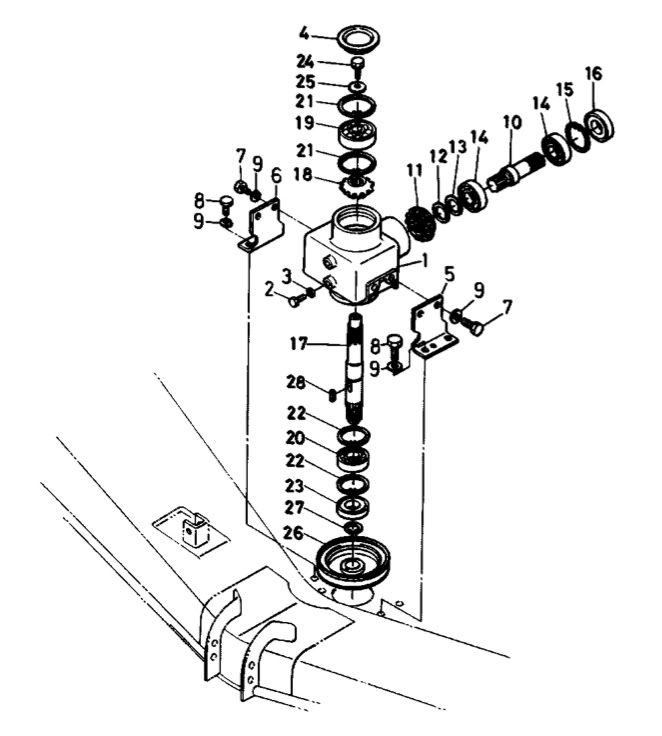

I have a Kubota mower deck RC60-71B, the gear box oil leaked out and I need a top bearing (first one to overheat) and the oil seal at the bottom of the gear box (where the oil leaked out). I have removed the top bearing no problem, but I can't tell just what to do next to remove the lower bearing(?) to get to the oil seal. Can anyone help me with a short step-by-step explanation?

Just replacing the bearings and seals will correct SOME of the out-of-balance play and vibration; but not all of it. The gearbox input shaft is very poorly-designed: supported by two 6205 [25x52x15] ball bearings, that are mounted virtually back-to-back. There is only 9/16" separation between them; so their resistance to sideways forces is minimal.

And those sideways forces can be considerable, since the PTO shaft typically operated at an angle about 15 degrees, in the case of my mower. So the bearings wear out quickly, and the resultant play wrecks the seals. Then the oil runs out; and the gearbox seizes. LOVELY . . . .

UPGRADES

1: Make sure the bearings you fit are close-tolerance: at least ABEC-3; preferably ABEC-5. And close fit as well: CM or CN, rather than the usual C3 [loose fit]. That will help - for a time.

2: Replace the ball bearings with cylindrical roller bearings: flanged NJ205 bearings are 25x52x15, so will fit right in. Limited resistance to axial thrust; but much higher sideways resistance.

3: Do away with the oil seal, and replace it with ANOTHER bearing, with its own oil seals. That's a 6205 2RS. That means leaving out the internal circlip, drilling and tapping 5/32" holes around the end face of the gearbox housing casting [I drill 6; you could go to 8]. Making up a clamp ring-plate to bolt round the shaft and onto the casting end. Using that to clamp and hold in the outer of the TWO bearings. If you want, you could then make the inner of the two bearings an NJ205 roller, for more strength - since the two ball bearings will take care of end thrust.

Finally, if you want to back up the built-in seals in the 6205 2RS, you can take a standard 25x52x10 oilseal, grind off the sidewalls [leaving just the flat disc] and install that under the clamp plate as an additional seal.

4: Carry out the same gearbox housing modification as [3] above. But, in place of an extra bearing replace BOTH ball bearings with Taper Roller bearings. The 30205 is 25x52x16.25 so, to get the gear wheel properly positioned, you have to machine 1.25mm off the inner and outer shells of the inside bearing. If you take a wider 25x52x22 taper roller for the outer bearing, and add a 10mm oilseal, that will protrude from the housing, and you use the ring clamp frame to apply the necessary preload - through the oilseal - for the taper rollers.

Four solutions, in rough order of effort needed, and resulting strength.

But God knows why Kubota made such a crappy design in the first place . . . .