Was at my dealer today..

- Thread starter SidecarFlip

- Start date

Hopefully they are small rounds and not the 1000 pound plus ones I roll.... My customer like big ones. so I make them big and I keep the bale tension tight too. I usually roll 60's

My customer like big ones. so I make them big and I keep the bale tension tight too. I usually roll 60's

The way it was told to me by Dale (the head mechanic at my dealer), he said the issue was with side thrust like having the front in a dead furrow and cranking the wheels and trying to power out.

I'd say if you re careful about not doing that, should be no problem but then you already have a problem by the looks of your outboard.

I get one on the front and one on the back and start trucking across a field, I can still feel every bump. Like riding in boat on choppy water...

Next time I'm there at the dealer, I'll ask Dale where they switch from balls to rollers. I do know the outboards on the M's look entirely different than the smaller models and I I remember correctly, the outboards on my 5030 that I sold and the M's outboard gear cases were similar but the M has more neat in the castings.

The way it was told to me by Dale (the head mechanic at my dealer), he said the issue was with side thrust like having the front in a dead furrow and cranking the wheels and trying to power out.

I'd say if you re careful about not doing that, should be no problem but then you already have a problem by the looks of your outboard.

I get one on the front and one on the back and start trucking across a field, I can still feel every bump. Like riding in boat on choppy water...

Next time I'm there at the dealer, I'll ask Dale where they switch from balls to rollers. I do know the outboards on the M's look entirely different than the smaller models and I I remember correctly, the outboards on my 5030 that I sold and the M's outboard gear cases were similar but the M has more neat in the castings.

The last bunch of rounds have averaged around 950 each. It has been good hay at a good price. I usually put the spear on the back and move them but sometimes I get in a hurry and put them out with the pallet forks. Won’t be doing that anymore  Never imagined I would be moving round bales when I bought the tractor or I would have gotten a larger one Might have to find smaller bales.

Never imagined I would be moving round bales when I bought the tractor or I would have gotten a larger one Might have to find smaller bales.

dandeman

Member

Equipment

BX2230, LA211 FEL, RCK60B Mower, GCK60BX Bagger; Ford 4000, bush hog, blade, etc

And confirming.. I bought the factory service manuals at the time I bought my BX2230 and it shows ball bearings in the front wheel hubs that would be subject to lateral stress..

At least good to learn from this thread to be careful imposing heavy lateral loads on the front wheels.. Had always wondered anyway about the front axle handling the loads from the FEL.

At least good to learn from this thread to be careful imposing heavy lateral loads on the front wheels.. Had always wondered anyway about the front axle handling the loads from the FEL.

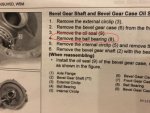

Looked in the manual for L3560 and other L60 tractors and the section on Bevel Gear case and Gears also refers to ball bearings, assuming I am looking in the right spot. Two bevel gears, one with what appears to be a race of ball bearings in the picture, and one without. There are subtle differences between the smaller two L60s and the 47 and up. An O ring and torque values, but nothing to make me think they had shifted to a different kind of bearing in the bigger Ls.

Interesting. Glad to know about it. Just because you have power steering doesn't mean you should use it!

Interesting. Glad to know about it. Just because you have power steering doesn't mean you should use it!

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Guess what you don't, and the head mechanic is an idiot!Glad I have tapered rollers. I would have blown mine out years ago.

Kubota does not use tapered bearings.

Go back to your dealer, grab head mechanic by the shirt collar and slap him...do the same to the owner for hiring him, then I hope he does the same back to you for believing him!

This is exactly how bad information gets propagated!

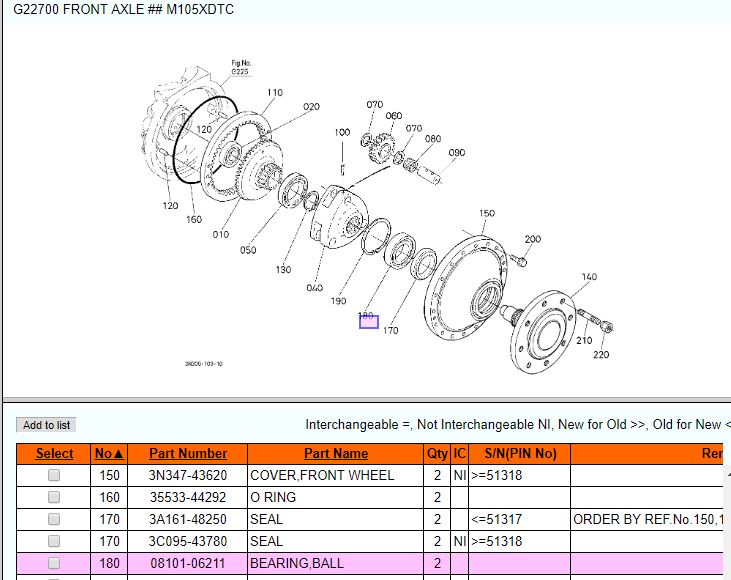

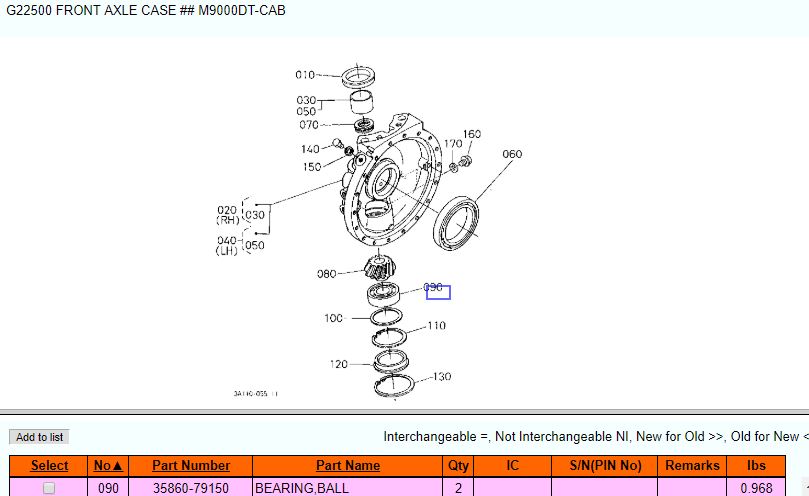

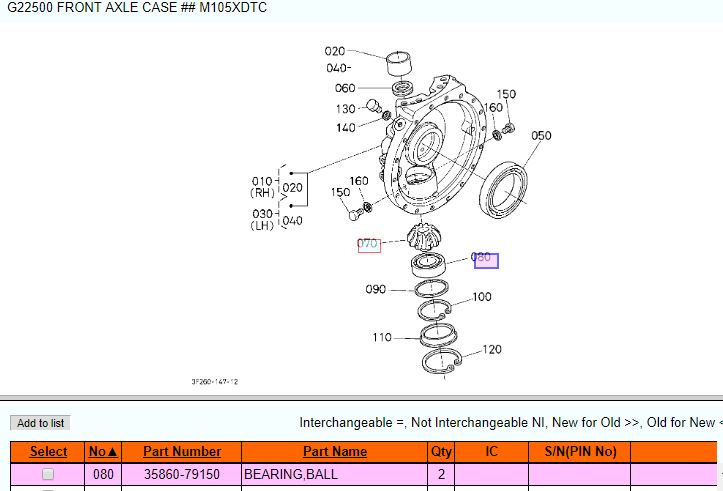

Here are your 2 tractors, same setup as all the rest, so yes you can suffer the same fate!

Attachments

-

77.3 KB Views: 715

-

83.5 KB Views: 776

-

52.2 KB Views: 705

-

52.6 KB Views: 689

Last edited:

BAP

Well-known member

Lifetime Member

Equipment

2012 Kubota 2920, 60MMM, FEL, BH65 48" Bush Hog, 60"Backblade, B2782B Snowblower

That is actually a very common setup across most brands of tractors with MFWA. I have been inside of Ford, John Deere, Case Construction and CaseIH front ends and they all are basically the same.Guess what you don't, and the head mechanic is an idiot!

Kubota does not use tapered bearings.

Go back to your dealer, grab head mechanic by the shirt collar and slap him...do the same to the owner for hiring him, then I hope he does the same back to you for believing him!

This is exactly how bad information gets propagated!

Here are your 2 tractors, same setup as all the rest, so yes you can suffer the same fate!

I said I didn't know and was just passing on what I was told. Looks to me like 050 is a tapered roller bearing, but then I could be mistaken. Far as mis information goes, only what I was told and nothing more and I stated that in the initial post.

Never had an issue myself. Don't want one either.

Never had an issue myself. Don't want one either.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

One more time... Kubota does not use tapered bearings.I said I didn't know and was just passing on what I was told. Looks to me like 050 is a tapered roller bearing, but then I could be mistaken. Far as mis information goes, only what I was told and nothing more and I stated that in the initial post.

Never had an issue myself. Don't want one either.

Attachments

-

63.4 KB Views: 725

OK... good info all around.

Now then, what part #s do I give Messick's to get tapered rollers so these ball bearings dont strand me?

Now then, what part #s do I give Messick's to get tapered rollers so these ball bearings dont strand me?

Let me refer to my original post.....

Was talking to the head mechanic who I know from hunting and the subject of smaller Kubby's came up because he had a BX tore apart (front axle) and I asked him what the issue was.

he told me he regularly rebuilds front axles because Kubota uses ball bearings in the outboard drives on the smaller units and they won't take side thrust very well. I asked him what he meant and he said like being in a rut with the front bucket full and cranking the steering wheel to attempt to get out of the rut. He said it blows the balls right out of the race and then he gets to rebuild them.

True or not, I have no idea other than looking at the carnage in the one he had apart.

Naturally, I asked him if the bigger ones were the same way (my M's). he said no, the larger Kubota tractors use tapered rollers. I'm happy. I do a bit of twist and shout at times.

If in fact my M's have ball bearings or not is kind of irrevelant. First off, I think what Dale was referring to was taking the tractors over design limits by adding rear weight, loaded rear tires and then loading the front bucket as full as the tractor will lift (and we all know that any Kubota will loft the rear wheels) because the loaders have capacity to lift beyond the design capabilities of the tractor they are on, you know that and so do I.

I never exceed the capacity of my loaders never have. My loaders are well within capabilities of lifting 2000 pounds and the most I have out front is a tad over 1000 pounds at any time.

Far as BAP calling someone he don't know an idiot, I've learned in my almost 70 years on this planet that usually people that call someone an idiot are idiots themselves.

Dale is a Kubota Factory Certified technician. If he tells me something, especially something I know nothing about, I have to believe him. He works on Kubota's every day.

I have to ask are you a factory certified Kubota technician?

I stated that plainly in my original post that I was told that by Dale. I didn't dream up the dialogue.

If it's true or false, I have no idea, Just passing on what I was told, nothing more.

Was talking to the head mechanic who I know from hunting and the subject of smaller Kubby's came up because he had a BX tore apart (front axle) and I asked him what the issue was.

he told me he regularly rebuilds front axles because Kubota uses ball bearings in the outboard drives on the smaller units and they won't take side thrust very well. I asked him what he meant and he said like being in a rut with the front bucket full and cranking the steering wheel to attempt to get out of the rut. He said it blows the balls right out of the race and then he gets to rebuild them.

True or not, I have no idea other than looking at the carnage in the one he had apart.

Naturally, I asked him if the bigger ones were the same way (my M's). he said no, the larger Kubota tractors use tapered rollers. I'm happy. I do a bit of twist and shout at times.

If in fact my M's have ball bearings or not is kind of irrevelant. First off, I think what Dale was referring to was taking the tractors over design limits by adding rear weight, loaded rear tires and then loading the front bucket as full as the tractor will lift (and we all know that any Kubota will loft the rear wheels) because the loaders have capacity to lift beyond the design capabilities of the tractor they are on, you know that and so do I.

I never exceed the capacity of my loaders never have. My loaders are well within capabilities of lifting 2000 pounds and the most I have out front is a tad over 1000 pounds at any time.

Far as BAP calling someone he don't know an idiot, I've learned in my almost 70 years on this planet that usually people that call someone an idiot are idiots themselves.

Dale is a Kubota Factory Certified technician. If he tells me something, especially something I know nothing about, I have to believe him. He works on Kubota's every day.

I have to ask are you a factory certified Kubota technician?

I stated that plainly in my original post that I was told that by Dale. I didn't dream up the dialogue.

If it's true or false, I have no idea, Just passing on what I was told, nothing more.

Somewhere in this thread I missed something, "Far as BAP calling someone he don't know an idiot, I've learned in my almost 70 years on this planet that usually people that call someone an idiot are idiots themselves."

Flip, where did that come from?

Flip, where did that come from?

It was a misunderstanding. BAP was actually quoting NIW, who was giving Flip a hard time, telling him to give his hunting buddy a cuff upside the head, is how I took it.

In any case the takehome message is clear. If you horse your wheel with power steering and the wheel can't turn you can do some damage. Would make sense if more common in BXs.

Flip if you ask Dale your tech friend about it, see if he might be misremembering a different gear bearing combination from somewhere else. Used to happen to me only different species and different body parts

In any case the takehome message is clear. If you horse your wheel with power steering and the wheel can't turn you can do some damage. Would make sense if more common in BXs.

Flip if you ask Dale your tech friend about it, see if he might be misremembering a different gear bearing combination from somewhere else. Used to happen to me only different species and different body parts

Flip is quick to believe anything he is told regarding these little BX "hobbyist" tractors..... they are not real equipment to him so any chance to knock them is fun.

my bail is is bigger than your bail....

my bail is is bigger than your bail....

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

SidecarFlip,

We need to make a few things perfectly clear:

#1: I was the one that called your head mechanic an idiot, me NIW not BAP.

It was more of an off the cuff comment as to his misinformation in telling you that your M's had taper bearings, so it was better than a BX, Not the case at all.

FYI: I have far more than enough mechanical experience and don't need a degree from Kubota Tech school to know how to read parts specs and a WSM.

This isn't the first dealer or dealership mechanic that I've called an idiot and I'm 100% sure it won't be the last!

If they make idiotic statements, that makes them an idiot right?

#2: Your M's DO NOT have taper bearings, this is not a maybe point , it's 100% fact, I thought I proved that beyond a shadow of a doubt, by posting up Kubota's own parts prints on the subject.

Your head mechanic must not know how to access them or he would not be telling you false information.

You saying "If in fact my M's have ball bearings or not is kind of irrelevant." WHAT... It's totally relevant it's the reason for this discussion.

#3: I'm sorry if offends your sense of right and wrong, But this is not the first time I've stumbled across your misleading information, and I don't like it. when you post misleading information it leads others to believe what your saying is a fact when it's anything but!

#4: You say something ("Glad I have tapered rollers. I would have blown mine out years ago.") then you backpedal like mad to get out of it, if you say it you better be able to back it up with facts or bow gracefully when someone call you out on it.

We need to make a few things perfectly clear:

#1: I was the one that called your head mechanic an idiot, me NIW not BAP.

It was more of an off the cuff comment as to his misinformation in telling you that your M's had taper bearings, so it was better than a BX, Not the case at all.

FYI: I have far more than enough mechanical experience and don't need a degree from Kubota Tech school to know how to read parts specs and a WSM.

This isn't the first dealer or dealership mechanic that I've called an idiot and I'm 100% sure it won't be the last!

If they make idiotic statements, that makes them an idiot right?

#2: Your M's DO NOT have taper bearings, this is not a maybe point , it's 100% fact, I thought I proved that beyond a shadow of a doubt, by posting up Kubota's own parts prints on the subject.

Your head mechanic must not know how to access them or he would not be telling you false information.

You saying "If in fact my M's have ball bearings or not is kind of irrelevant." WHAT... It's totally relevant it's the reason for this discussion.

#3: I'm sorry if offends your sense of right and wrong, But this is not the first time I've stumbled across your misleading information, and I don't like it. when you post misleading information it leads others to believe what your saying is a fact when it's anything but!

#4: You say something ("Glad I have tapered rollers. I would have blown mine out years ago.") then you backpedal like mad to get out of it, if you say it you better be able to back it up with facts or bow gracefully when someone call you out on it.

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Thank you, that was 100% my point of the statement!It was a misunderstanding. BAP was actually quoting NIW, who was giving Flip a hard time, telling him to give his hunting buddy a cuff upside the head, is how I took it.

Last edited:

Did an M-40 series a month or so ago.

All ball bearings.

All of the L series, ball bearings.

My MF 1140 & 1145. Ball bearings. Did and Agco today. Ball bearings. Did a 790 JD a few weeks ago, ball bearings.

Ball bearings will take an axial load just fine, but they have their limits. Usually the limit is listed if you look up the bearing by number.

Kubota bearings are usually common sizes and easily cross referenced by extracting the bearing number out of the part number. Thing is.....Kubota sells them cheaper than most bearing supply places...and they're usually a good brand, SKF for a lot of them, Timken for some, etc etc. Just went through this on my G1900..deck spindle bearings...Kubota price $10.45 each (at dealer, not counting employee discount)...bearing supply place in town, cheapest they had were $14.88 ea for Chinese ones and $20+ ea for decent ones. Worth mentioning, and worth checking into if you need any bearings. I usually get them all from Kubota. A certain mower brand's deck bearings are sold for about $30 a piece if you get them direct from the manufacturer...same bearing from Kubota is $14. 08101-06006 I think they are.

....And yes I'm a factory trained tech. JD for a while, Kubota now. I like doing front drive repairs. Easy work (usually) but they can take a while sometimes depending on if I've got to flush the junk out of the diff and/or housing(s).

All ball bearings.

All of the L series, ball bearings.

My MF 1140 & 1145. Ball bearings. Did and Agco today. Ball bearings. Did a 790 JD a few weeks ago, ball bearings.

Ball bearings will take an axial load just fine, but they have their limits. Usually the limit is listed if you look up the bearing by number.

Kubota bearings are usually common sizes and easily cross referenced by extracting the bearing number out of the part number. Thing is.....Kubota sells them cheaper than most bearing supply places...and they're usually a good brand, SKF for a lot of them, Timken for some, etc etc. Just went through this on my G1900..deck spindle bearings...Kubota price $10.45 each (at dealer, not counting employee discount)...bearing supply place in town, cheapest they had were $14.88 ea for Chinese ones and $20+ ea for decent ones. Worth mentioning, and worth checking into if you need any bearings. I usually get them all from Kubota. A certain mower brand's deck bearings are sold for about $30 a piece if you get them direct from the manufacturer...same bearing from Kubota is $14. 08101-06006 I think they are.

....And yes I'm a factory trained tech. JD for a while, Kubota now. I like doing front drive repairs. Easy work (usually) but they can take a while sometimes depending on if I've got to flush the junk out of the diff and/or housing(s).

Last edited:

For high thrust (side loading) you want to buy angular contact ball bearings. If you want them to last almost forever, with regular maintenance, buy precision angular contact ball bearings. They come in most, if not all of the sizes that regular ball bearings come in. The angular contact ball bearing is what is used in live center for supporting a work piece in a lathe with the tailstock.

They are installed with the inner race facing the source of thrust (or the most common source of thrust).

They are installed with the inner race facing the source of thrust (or the most common source of thrust).

Flipster took a fact-based beatdown in this one.

My countenance beams down upon this thread in satisfaction.

My countenance beams down upon this thread in satisfaction.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

One issue with tractor use is the thrust load changes constantly.For high thrust (side loading) you want to buy angular contact ball bearings. If you want them to last almost forever, with regular maintenance, buy precision angular contact ball bearings. They come in most, if not all of the sizes that regular ball bearings come in. The angular contact ball bearing is what is used in live center for supporting a work piece in a lathe with the tailstock.

They are installed with the inner race facing the source of thrust (or the most common source of thrust).

Side to side and up and down!