I went down a rabbit hole a few months ago after buying a used Buhler/Farm King hydraulic rear blade. The blade came with three hydraulic cylinders with one for boom offset, one for blade angle and one for blade tilt. The owner's manual shows an optional gauge wheel set up with two wheels and an optional hydraulic cylinder to control the height of the blade. So three rear remotes but four cylinders, which is a problem that I've run into repeatedly since I have top-n-tilt on both tractors i.e. hydraulic top link and hydraulic lift rod link. The flail mower and the snow blower both need two rear remotes, and the rear blade needs three, so I'm often left deciding whether to give up the top link or the lift rod link when running those implements.

I tend to like more features than less, and the idea of using the rear blade like a road grader with the blade centered between two axles that are far apart appeals to me. However, with only three rear remotes on each tractor I would need to add another set of remotes on both.

I was slow to catch on, but @MtnViewRanch made the point that I could operate all four cylinders on one implement using one lever in the cab and a control grip from Scorpion Technologies or similar. Last November I ordered a Scorpion X Series grip with four momentary buttons in a diamond pattern to make it easy to remember which button controls which cylinder when running the rear blade. Basically, you hold down a button (momentary) to allow oil to flow through one pair of outlets, and then move the lever to control a cylinder or motor connected to those outlets. Summit Hydraulics provides switch boxes or rocker switches that allow the lever to control multiple cylinders at the same time, but that's a not a function that I need or want, so momentary switches works for me.

I was putting off buying the multipliers until the Spring, but Summit Hydraulics has a St. Patrick's Day 15% discount through 3/17 so this seemed like the perfect time to order 4 circuit and 3 circuit hydraulic multipliers for both tractors. Also, a Scorpion S Series three-button control grip from Canada for the MX before the tariffs drive the cost up. I have no intention of running the Buhler/Farm King rear blade on the MX given the size and weight of the blade, but controlling a snow blower chute and deflector as well as one of the hydraulic top-n-tilt cylinders, or controlling flail offset and cutting head angle along with a top-n-tilt cylinder all from the one lever is appealing.

There is something that I ran into though and it's a comment I noticed in the installation instructions for the Scorpion X Series.

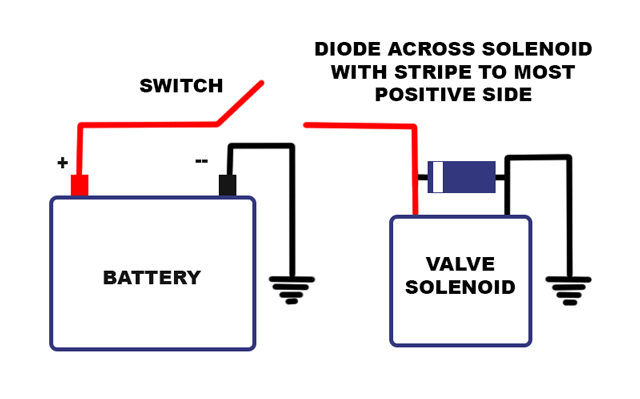

NOTE:

Switch life will be greatly reduced if snubber diodes are not used across inductive loads. (ie relay

and solenoid coils).

2 amp diodes should be installed across the 2 terminals on the solenoids. The striped end of the

diode should be attached to the positive solenoid terminal (wire from the switch) and the other end

of the diode attached to the negative (ground) solenoid terminal.

If a diode pack has been included with the wiring harness, the Black wire emerging from the diode

pack should be attached to ground.

When I spoke with the salesman at Scorpion Technologies this afternoon I asked if he knew whether or not the solenoids that were coming with the multipliers had diodes in them. He didn't know so I called Summit this afternoon and the person I spoke with wasn't sure either, but assured me that he'd find out and send me an email once he knew. As I was going down another rabbit hole doing my own research re the solenoids, I received an email from Summit stating that the Hydraforce SV10-41 solenoids do in fact have Zener diodes in them to protect the buttons used to control them. Phew! Good news and great service from Summit and Scorpion both. I sent and email to Scorpion Technologies informing them of this since they regularly get calls from customers asking about Summit Hydraulics and Scorpion control grips.

I'm looking forward to making up custom brackets to bolt these chunks of aluminum to the rear of both tractors. Here are the pieces of this puzzle to be installed in the Spring. I'll update this thread as I accompish various parts of the installation such as the mounting brackets, modifications to the levers in the cab to accept the control grips, hoses to run from one set of remotes to the valve body, wiring, testing,etc.

Summit Hydraulics 3 circuit and 4 circuit hydraulic multipliers.

Scorpion Technologies X Series and S Series control grips.

I tend to like more features than less, and the idea of using the rear blade like a road grader with the blade centered between two axles that are far apart appeals to me. However, with only three rear remotes on each tractor I would need to add another set of remotes on both.

I was slow to catch on, but @MtnViewRanch made the point that I could operate all four cylinders on one implement using one lever in the cab and a control grip from Scorpion Technologies or similar. Last November I ordered a Scorpion X Series grip with four momentary buttons in a diamond pattern to make it easy to remember which button controls which cylinder when running the rear blade. Basically, you hold down a button (momentary) to allow oil to flow through one pair of outlets, and then move the lever to control a cylinder or motor connected to those outlets. Summit Hydraulics provides switch boxes or rocker switches that allow the lever to control multiple cylinders at the same time, but that's a not a function that I need or want, so momentary switches works for me.

I was putting off buying the multipliers until the Spring, but Summit Hydraulics has a St. Patrick's Day 15% discount through 3/17 so this seemed like the perfect time to order 4 circuit and 3 circuit hydraulic multipliers for both tractors. Also, a Scorpion S Series three-button control grip from Canada for the MX before the tariffs drive the cost up. I have no intention of running the Buhler/Farm King rear blade on the MX given the size and weight of the blade, but controlling a snow blower chute and deflector as well as one of the hydraulic top-n-tilt cylinders, or controlling flail offset and cutting head angle along with a top-n-tilt cylinder all from the one lever is appealing.

There is something that I ran into though and it's a comment I noticed in the installation instructions for the Scorpion X Series.

NOTE:

Switch life will be greatly reduced if snubber diodes are not used across inductive loads. (ie relay

and solenoid coils).

2 amp diodes should be installed across the 2 terminals on the solenoids. The striped end of the

diode should be attached to the positive solenoid terminal (wire from the switch) and the other end

of the diode attached to the negative (ground) solenoid terminal.

If a diode pack has been included with the wiring harness, the Black wire emerging from the diode

pack should be attached to ground.

When I spoke with the salesman at Scorpion Technologies this afternoon I asked if he knew whether or not the solenoids that were coming with the multipliers had diodes in them. He didn't know so I called Summit this afternoon and the person I spoke with wasn't sure either, but assured me that he'd find out and send me an email once he knew. As I was going down another rabbit hole doing my own research re the solenoids, I received an email from Summit stating that the Hydraforce SV10-41 solenoids do in fact have Zener diodes in them to protect the buttons used to control them. Phew! Good news and great service from Summit and Scorpion both. I sent and email to Scorpion Technologies informing them of this since they regularly get calls from customers asking about Summit Hydraulics and Scorpion control grips.

I'm looking forward to making up custom brackets to bolt these chunks of aluminum to the rear of both tractors. Here are the pieces of this puzzle to be installed in the Spring. I'll update this thread as I accompish various parts of the installation such as the mounting brackets, modifications to the levers in the cab to accept the control grips, hoses to run from one set of remotes to the valve body, wiring, testing,etc.

Summit Hydraulics 3 circuit and 4 circuit hydraulic multipliers.

Scorpion Technologies X Series and S Series control grips.