I keep my LP grappler in a shed. But it gets pretty hot in there. Last time when I went to connect the hydraulic lines. It had some much pressure I couldn’t connect. Is there any way to relieve the pressure other than pushing on the when I go to connect with a piece of wood or a screw driver

Pressure on Hydraulic lines

- Thread starter kcs

- Start date

Have a L3130 Also have a grapple sits outside. Just don't think temp change 50 or 60 degrees expandes the oil that much. Maby the grapple was not all the way closed when you removed it. This will put psi on one of lines. I have done this. I use a 1/4" punch rag & tap the pin in to relive psi. The flat face on a punch will not damage the pin a screwdriver will work but harder to keep on the pin. my 2 cents

Last edited:

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

The oil cannot expand so thats not how it works in the case ov a gas the Ideal Gas law defines the relationship:Just don't think temp change 50 or 60 degrees expandes the oil that much.

PV =nRT

So what is the relationship for a petroleum oil. Interesting question and Google returned a very unteresting P v T answer. Next time it happens might be educational to test the.effect of a couple ice packs applied to the cylinders. Or for a more immediate result couple the hoses together with a pressure gauge in the middle and apply a heat gun to the cylinders. Looks like a small delta T produces a big change.

Dan

Last edited:

NCL4701

Well-known member

Equipment

L4701, T2290, WC68, grapple, BB1572, Farmi W50R, Howes 500, 16kW IMD gen, WG24

The male poppet type, you can whack it with a hardwood block/mallet to relieve pressure. A brass punch also works. Females are a bit harder to deal with (shocking, I know). You can unscrew the fitting a bit to relieve pressure but arguably not ideal SOP.

There are a variety of tools designed to assist with the issue. Example:https://www.amazon.com/Original-Hydraulic-Coupling-Pressure-Decompression/dp/B0BRTB5W4B

I don’t have any sort of decompression tool so not making a recommendation, just pointing out there are a variety of options.

There are a variety of tools designed to assist with the issue. Example:https://www.amazon.com/Original-Hydraulic-Coupling-Pressure-Decompression/dp/B0BRTB5W4B

I don’t have any sort of decompression tool so not making a recommendation, just pointing out there are a variety of options.

fwiw: over the decades I have become accustomed to whenever I take a hydraulic piece of equipment off, on the impliment side I give the poppet of both the male and female end a quick push in.

A small amount fluid bleeds into the rag.

Bleeding off a little fluid each time I change an implement (fingers stay crossed) seems to keep almost all my connection problems away.

I also cycle the tractor controls with acc. on but engine off prior to hooking stuff up to bleed off pressure from tractor side. Sometimes I even give the poppets a push in before facing the implement.

I keep small wooden dowls scatted around my shops for making this work.

A small amount fluid bleeds into the rag.

Bleeding off a little fluid each time I change an implement (fingers stay crossed) seems to keep almost all my connection problems away.

I also cycle the tractor controls with acc. on but engine off prior to hooking stuff up to bleed off pressure from tractor side. Sometimes I even give the poppets a push in before facing the implement.

I keep small wooden dowls scatted around my shops for making this work.

I'll put a clean rag to cover the end before tapping with a mallet. Stops oil spray.The male poppet type, you can whack it with a hardwood block/mallet to relieve pressure. A brass punch also works. Females are a bit harder to deal with (shocking, I know). You can unscrew the fitting a bit to relieve pressure but arguably not ideal SOP.

There are a variety of tools designed to assist with the issue. Example:https://www.amazon.com/Original-Hydraulic-Coupling-Pressure-Decompression/dp/B0BRTB5W4B

I don’t have any sort of decompression tool so not making a recommendation, just pointing out there are a variety of options.

BAP

Well-known member

Lifetime Member

Equipment

2012 Kubota 2920, 60MMM, FEL, BH65 48" Bush Hog, 60"Backblade, B2782B Snowblower

Take and change the couplers on your grapple and tractor so that each has a male end and a female end. That way when you take off the grapple you can couple the hoses together. If coupled together then they equalize the oil in the hoses as temperature changes and will be easy to hook up.

If you do that, leave the grapple in a middle position, if it is at the end of travel pressure can still build as it tries to force the immovable cylinder.Take and change the couplers on your grapple and tractor so that each has a male end and a female end. That way when you take off the grapple you can couple the hoses together. If coupled together then they equalize the oil in the hoses as temperature changes and will be easy to hook up.

Best (not least expensive) solution is a set of flat-faced couplers.I keep my LP grappler in a shed. But it gets pretty hot in there. Last time when I went to connect the hydraulic lines. It had some much pressure I couldn’t connect. Is there any way to relieve the pressure other than pushing on the when I go to connect with a piece of wood or a screw driver

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

Actually if it's fully retracted it can and will still move. If its fully extended it can't.If you do that, leave the grapple in a middle position, if it is at the end of travel pressure can still build as it tries to force the immovable cylinder.

Dan

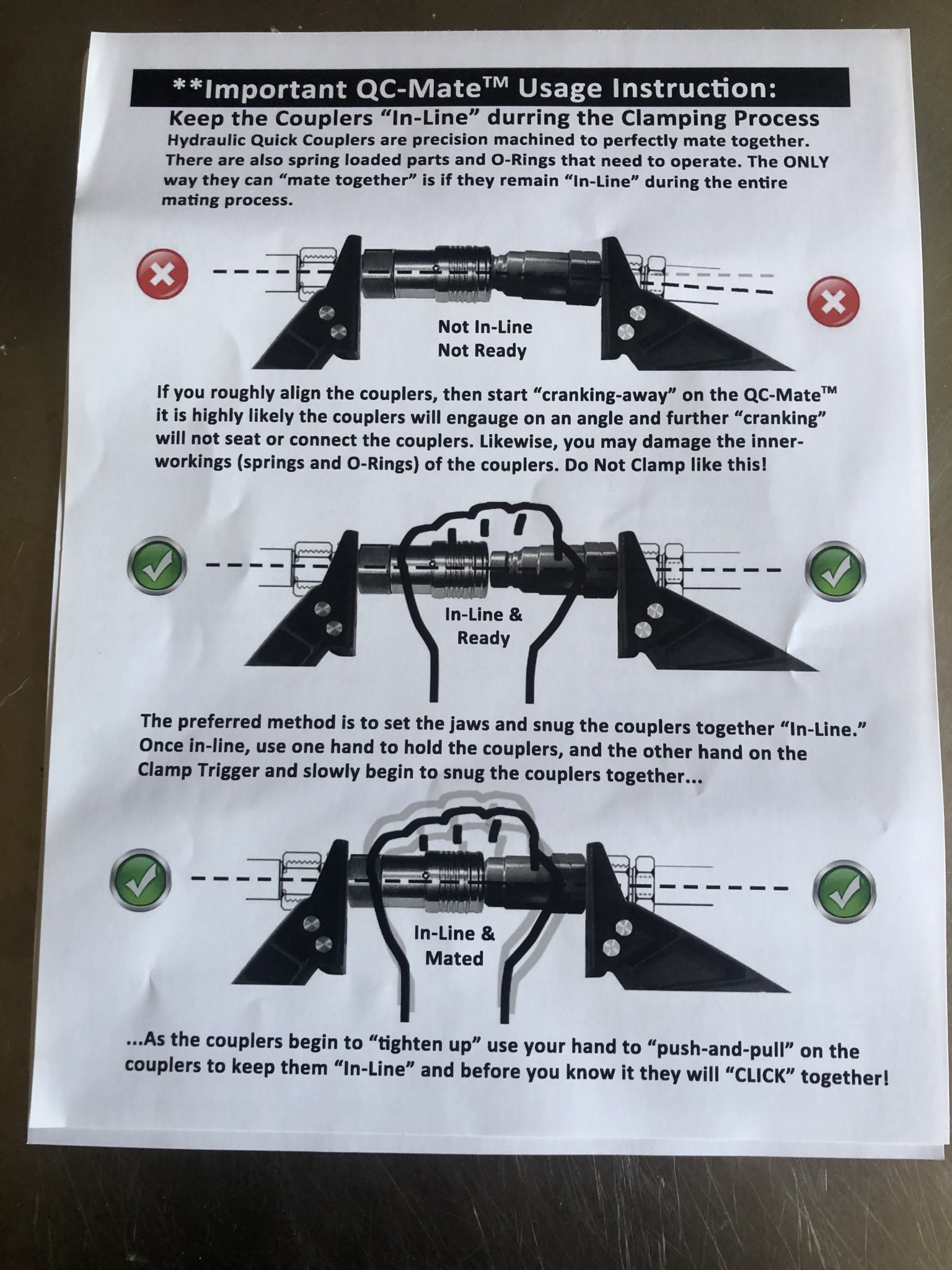

I only have this issue with the flat face couplers. Am I doing something wrong?Best (not least expensive) solution is a set of flat-faced couplers.

lgeist04

New member

Equipment

MX6000 HSTC, LP RCF2060, LP SGC1060, Woodland Mills WG24, Titan forks.

Leave the grapple all the way open when you disconnect the hoses. Then connect the hoses together allowing the grapple to close and the fluid in the lines to drain into the grapple cylinders. I have not had issues since I started doing this.

GBJeffOH

Active member

Equipment

L4060, EA Grapple, 6' LP Brush Hog, 8' snow plow, 6' LP tiller, EA Forks, Spraye

I soon as I unhook the attachment I hook this up. There is air in the black pipe. Once in a while I open the ball valve to let the oil out.I keep my LP grappler in a shed. But it gets pretty hot in there. Last time when I went to connect the hydraulic lines. It had some much pressure I couldn’t connect. Is there any way to relieve the pressure other than pushing on the when I go to connect with a piece of wood or a screw driver

Attachments

-

943.7 KB Views: 61

Older tractor equipment used agricultural type quick connectors. Not as easy to keep clean but easier to decompress. Gear tractors very tolerant hydraulic contamination. Construction equipment lead the flatface type QD, easy to wipe clean and better for hydraulic drive transmission. Also compliant to fluid loss on construction sites.

Most of my equipment is now converted to flatface QDs. Techniques described help connecting 95% of the time. I’m not as big of a gorilla as I once was so tools help too. Homemade or store bought.

Most of my equipment is now converted to flatface QDs. Techniques described help connecting 95% of the time. I’m not as big of a gorilla as I once was so tools help too. Homemade or store bought.

TheOldHokie

Well-known member

Lifetime Member

Equipment

L3901/LA525, B7200DT/B1630, G2160/RCK60, G2460/RCK60

The single biggest advantage of flat face couplers and the reason they are used on construction equipment is flow rate. A 1/2 body flst face coupler can handle twice the flow of an agricultural coupler and with less pressure drop.

If you don't need high flow you are not getting much for the substantial price premium.

Dan

If you don't need high flow you are not getting much for the substantial price premium.

Dan