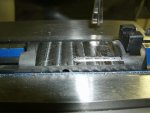

Going to install a red dot sight on my Sig P226. But it comes with some challenges, mostly with the milled pocket for lightening the slide weight (pic 2, vertical arrow) just happens to be right where one of the screws for the sight has to go. So my plan is to make an insert out of aluminum to fill the pocket(pic 3 and 4) so it will press into the slot. I added a little red loctite to secure it for the milling and tapping operation to follow. The plan is to mill down just far enough so the insert is exposed but not so far to allow it to pull out. Once drilled and tapped, the sight screw will hold it in place. More to come tomorrow.

Attachments

-

97.2 KB Views: 271

-

82.9 KB Views: 266

-

74.2 KB Views: 265

-

58 KB Views: 256

-

47.3 KB Views: 265