retiree-urgency abandoned

Member

Equipment

B3350, Kub. 5" rotary cutter, LP 48" forks, Titan Aerial Platform, KK XB Dump

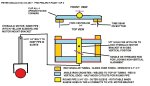

I started this conversation on Implements & Attachments to get some ideas and am no ready to finalize my design and start building this. My plan is to build a poor-man's equivalent of a Landpride SA-10. I'm going to cannibalize a gas powered PHD I bought at auction for this project. I was asked why I don't restore the PHD as-is and here's why:

1. Don't know what it would cost to get the original unit up & running - am not a mechanic, so motor would go to a repair shop (probably $100+ to get it running/tuned up) - recoil spring is about dead (more $). Also both tires are beat and flat - probably another $75+ and the 2 way hydraulic valve on the handle looked leaky ... you get my point. So I weighed repair costs (factoring in unknowns) against buying 4 ft. of rectangular steel tubing and the welding (by a shop) for my slide on.

2. Don't want to maintain yet another engine - the PHD will get very intermittent use - maybe once or twice a year in a normal year.

3. Don't want to have to tow it around and then bull it into place - am getting too old for that. It will be less work to slide the PHD onto the forks than swap regular drawbar for the one with trailer hitch on it.

4. Can store the new unit with augers on a single pallet - will take up less space

Have attached brochure photo of the PHD model. Will add to this thread is a proceed.

1. Don't know what it would cost to get the original unit up & running - am not a mechanic, so motor would go to a repair shop (probably $100+ to get it running/tuned up) - recoil spring is about dead (more $). Also both tires are beat and flat - probably another $75+ and the 2 way hydraulic valve on the handle looked leaky ... you get my point. So I weighed repair costs (factoring in unknowns) against buying 4 ft. of rectangular steel tubing and the welding (by a shop) for my slide on.

2. Don't want to maintain yet another engine - the PHD will get very intermittent use - maybe once or twice a year in a normal year.

3. Don't want to have to tow it around and then bull it into place - am getting too old for that. It will be less work to slide the PHD onto the forks than swap regular drawbar for the one with trailer hitch on it.

4. Can store the new unit with augers on a single pallet - will take up less space

Have attached brochure photo of the PHD model. Will add to this thread is a proceed.

Attachments

-

39.5 KB Views: 42