The hood opening and closing on my snowblower moves too quickly and I want to install a restrictor in the line to slow the movement. It is operated by a 3rd function valve. The Parker 4A789A is an adjustable metered flow valvea indicated by an arrow on the side of the valve. Which way should the valve arrow be placed? My thoughts are that the cylinder being filled should have the arrow facing the cylinder and the other one should face away from the cylinder. Also, should I use brass or steel close nipples to make the connections? Presently I have 2 steel close nipples.

Question about hydraulic hood on a BX2822 Snowblower.

- Thread starter DustyRusty

- Start date

You would install them opposite to each other and adjust as needed.

-->

<--

Technically brass should not be used in hydraulic circuits because of the pressure, but the deflector is and low load device so you'll be OK.

-->

<--

Technically brass should not be used in hydraulic circuits because of the pressure, but the deflector is and low load device so you'll be OK.

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

Use whatever nipples are rated for 2,000 PSI !!!

Those devices reduce flow not pressure

WARNING !!! Just looked them up ,saw this...

These valves control flow in a pneumatic circuit by increasing or decreasing the volume that passes through a line. They reduce the speed at which an actuator performs and allow air to flow in one direction only, allowing for free flow in the other direction.

They are for air use NOT hydraulic oil.

This one, https://www.princessauto.com/en/adjustable-line-throttle-valves/product/PA1000000783?skuId=8322869

is $119 Canucks....

Those devices reduce flow not pressure

WARNING !!! Just looked them up ,saw this...

These valves control flow in a pneumatic circuit by increasing or decreasing the volume that passes through a line. They reduce the speed at which an actuator performs and allow air to flow in one direction only, allowing for free flow in the other direction.

They are for air use NOT hydraulic oil.

This one, https://www.princessauto.com/en/adjustable-line-throttle-valves/product/PA1000000783?skuId=8322869

is $119 Canucks....

These are the exactly same ones that I used on a hydraulic motor that I have used to turn the chute on my BX22 long before Kubota started offering ways to turn the chute from inside of the cab. I doubt that the piston is going to know the difference.

Product Details

Catalog Page2358

BrandPARKER

Manufacturer Part NumberF800B

SeriesF

Valve TypeControl

Maximum Pressure2,000 psi

Maximum Flow Rate15 gpm

Inlet Connection1/2 in NPT

Inlet Connection GenderFemale

Outlet Connection1/2 in NPT

Outlet Connection GenderFemale

Adjustment MethodRotary Knob

Actuation MechanismManual

Valve ControlFlow Control

Control DirectionOne-Way

Cracking Pressure5 psi

Overall Length3.44 in

Overall Height3.33 in

Overall Width1.25 in

Port-to-Port Length2.23 in

Body MaterialBrass

Includes SealsSeals Included

Seal MaterialNitrile

MountingInline

Coefficient of Volume (Cv)0.976

Operating Temperature - Maximum250 °F

Operating Temperature - Minimum-40 °F

Fluid ServiceOil

UNSPSC40141609

Country of Origin USA (subject to change)

Product Description

General purpose flow control valves regulate fluid flow rates in one direction and are free-flowing in the opposite direction.

Product Details

Catalog Page2358

BrandPARKER

Manufacturer Part NumberF800B

SeriesF

Valve TypeControl

Maximum Pressure2,000 psi

Maximum Flow Rate15 gpm

Inlet Connection1/2 in NPT

Inlet Connection GenderFemale

Outlet Connection1/2 in NPT

Outlet Connection GenderFemale

Adjustment MethodRotary Knob

Actuation MechanismManual

Valve ControlFlow Control

Control DirectionOne-Way

Cracking Pressure5 psi

Overall Length3.44 in

Overall Height3.33 in

Overall Width1.25 in

Port-to-Port Length2.23 in

Body MaterialBrass

Includes SealsSeals Included

Seal MaterialNitrile

MountingInline

Coefficient of Volume (Cv)0.976

Operating Temperature - Maximum250 °F

Operating Temperature - Minimum-40 °F

Fluid ServiceOil

UNSPSC40141609

Country of Origin USA (subject to change)

Product Description

General purpose flow control valves regulate fluid flow rates in one direction and are free-flowing in the opposite direction.

Last edited:

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

love the internet..... one site says air ( the 1st one) , another says 'hydraulic', 3rd says parker no longer makes them,4th has them for $35 CDN........

What DR posts isn't the specs for the 4A789A unit. it's 1/4" NPT, not 1/2"

What DR posts isn't the specs for the 4A789A unit. it's 1/4" NPT, not 1/2"

To simplify things since this is a chute deflector and there's not going to be much difference between extend and retract speeds and there's very little load, go with a single needle valve plumbed into one of the hoses.

summit-hydraulics.com

summit-hydraulics.com

With a needle valve, you only need one and it'll meter the flow in both directions with nearly the same speed. The difference in speed is due to the difference in volume of the cylinder on the rod side of the piston vs non-rod side.

With the directional flow control in the first post- two will be needed (one per hose) and you'd want to meter the flow exiting the cylinder (known as meter-out).

Hydraulic Flow Control Needle Valve, 1/4" NPT Ports

Hydraulic Flow Control Valve w/ Free Bi-Directional Flow, 1/4″ NPT Ports Free Shipping

With a needle valve, you only need one and it'll meter the flow in both directions with nearly the same speed. The difference in speed is due to the difference in volume of the cylinder on the rod side of the piston vs non-rod side.

With the directional flow control in the first post- two will be needed (one per hose) and you'd want to meter the flow exiting the cylinder (known as meter-out).

BAP

Well-known member

Lifetime Member

Equipment

2012 Kubota 2920, 60MMM, FEL, BH65 48" Bush Hog, 60"Backblade, B2782B Snowblower

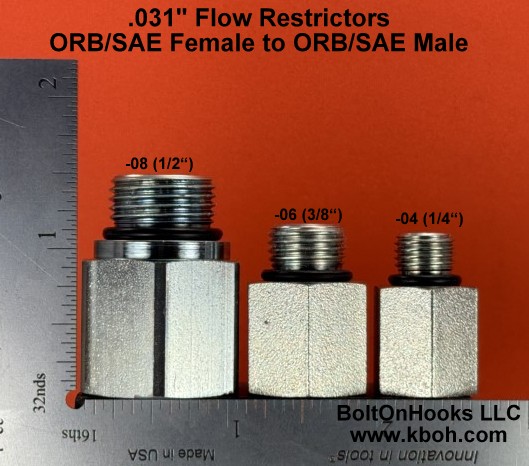

Unless you already own metered flow valves, restrictor fittings like those sold by Kennyd4110 are way more cheaper and just as effective.

These are the exactly same ones that I used on a hydraulic motor that I have used to turn the chute on my BX22 long before Kubota started offering ways to turn the chute from inside of the cab. I doubt that the piston is going to know the difference.

Same valve, lower cost:

Hydraulic Flow Control Needle Valve, 1/4" NPT Ports

Hydraulic Flow Control Valve w/ Free Bi-Directional Flow, 1/4″ NPT Ports Free Shippingsummit-hydraulics.com

Hydraulic In-Line Adjustable Variable Flow Control Valve w/ Free Reverse Flow, 1/4" SAE

Hydraulic In-Line Adjustable Variable Flow Control Valve w/ Free Reverse Flow, 1/4" SAE Free Shipping!

Would this be a better option:

.031" Flow Restrictor, ORB/SAE Female to ORB/SAE Male - BoltOnHooks LLC

.030 restrictor, .030, restrictor, top link restrictor, side link restrictor, top link, side link, TnT

Last edited:

Cost isn't an issue since I already have these two valves. The restrictors do look like a viable alternative, and my question is, do I need one on each hose or only one hose? The hoses are 1/4" NPT.

My understanding is just one. because they're a hole drilled in a fitting, so they restrict flow volume in both directions.

Yours have a check-valve so the flow is restricted in one direction and free-flowing the other, which in that case is why you'd need one in each line. Yours would allow for a different "up" verses "down" speed, or exactly the same speed whereas the restrictor I mentioned would flow faster when filling the side of the cylinder having the ram since the ram takes up space in the cylinder vs the non-ram side.

Yours have a check-valve so the flow is restricted in one direction and free-flowing the other, which in that case is why you'd need one in each line. Yours would allow for a different "up" verses "down" speed, or exactly the same speed whereas the restrictor I mentioned would flow faster when filling the side of the cylinder having the ram since the ram takes up space in the cylinder vs the non-ram side.

Short answer, it depends...and my question is, do I need one on each hose or only one hose?

Since those flow restrictors have arrows on them, they are probably free flowing in one direction and restrict in the other. If that is the case you'd two, as I described in my first reply...You can read where it says "metered flow" indicating that it only 'works' one way.

The simple fixed ones new sell are bidirectional, so you'd only "need' one.

For example, these are the type I described:

1/4 NPT 5 GPM Wolverine by Prince WFC-400 In-Line Flow Control | Wolverine by Prince Mfg | Brands | www.surpluscenter.com

1/4 NPT 5 GPM Wolverine by Prince WFC-400 In-Line Flow Control, Wolverine by Prince Mfg, 1/4 NPT 5 GPM PRINCE WFC-400 IN-LINE FLOW CONTROL, 1/4 NPTWolverine by Prince Mfg,WFC-400 ,

www.surpluscenter.com

While this one restricts flow in BOTH directions:

1/4 NPT 5 GPM Needle Valve Wolverine by Prince Mfg WNV-400 | Inline & Needle Valves | Flow Control Valves | Hydraulic Valves | Hydraulics | www.surpluscenter.com

1/4 NPT 5 GPM Needle Valve Wolverine by Prince Mfg WNV-400, Inline & Needle Valves, 1/4 NPT 5 GPM PRINCE WNV-400 NEEDLE VALVE, 1/4 NPT NEEDLE VALVE Prince Mfg,WNV-400 ,

www.surpluscenter.com