Wildfire

Active member

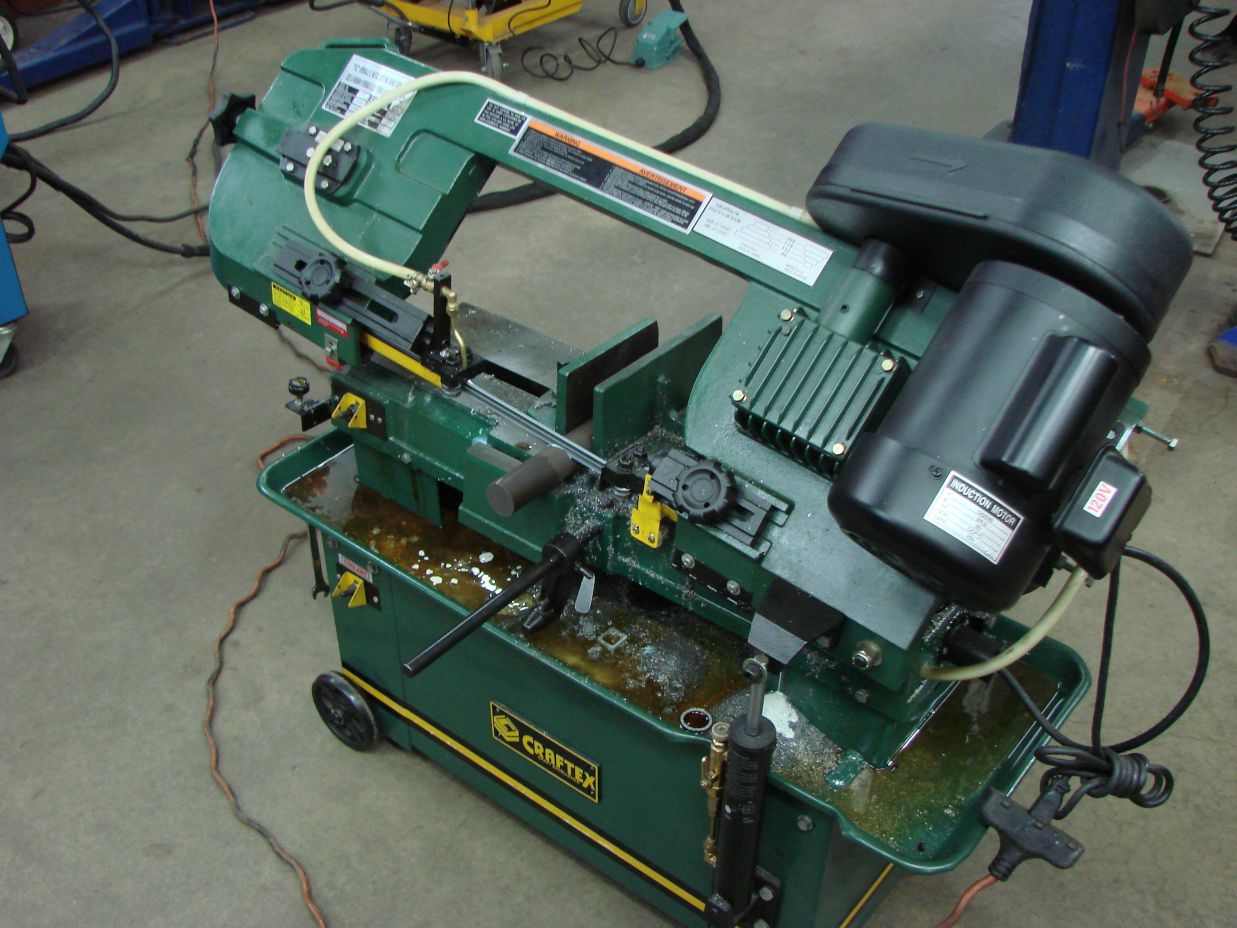

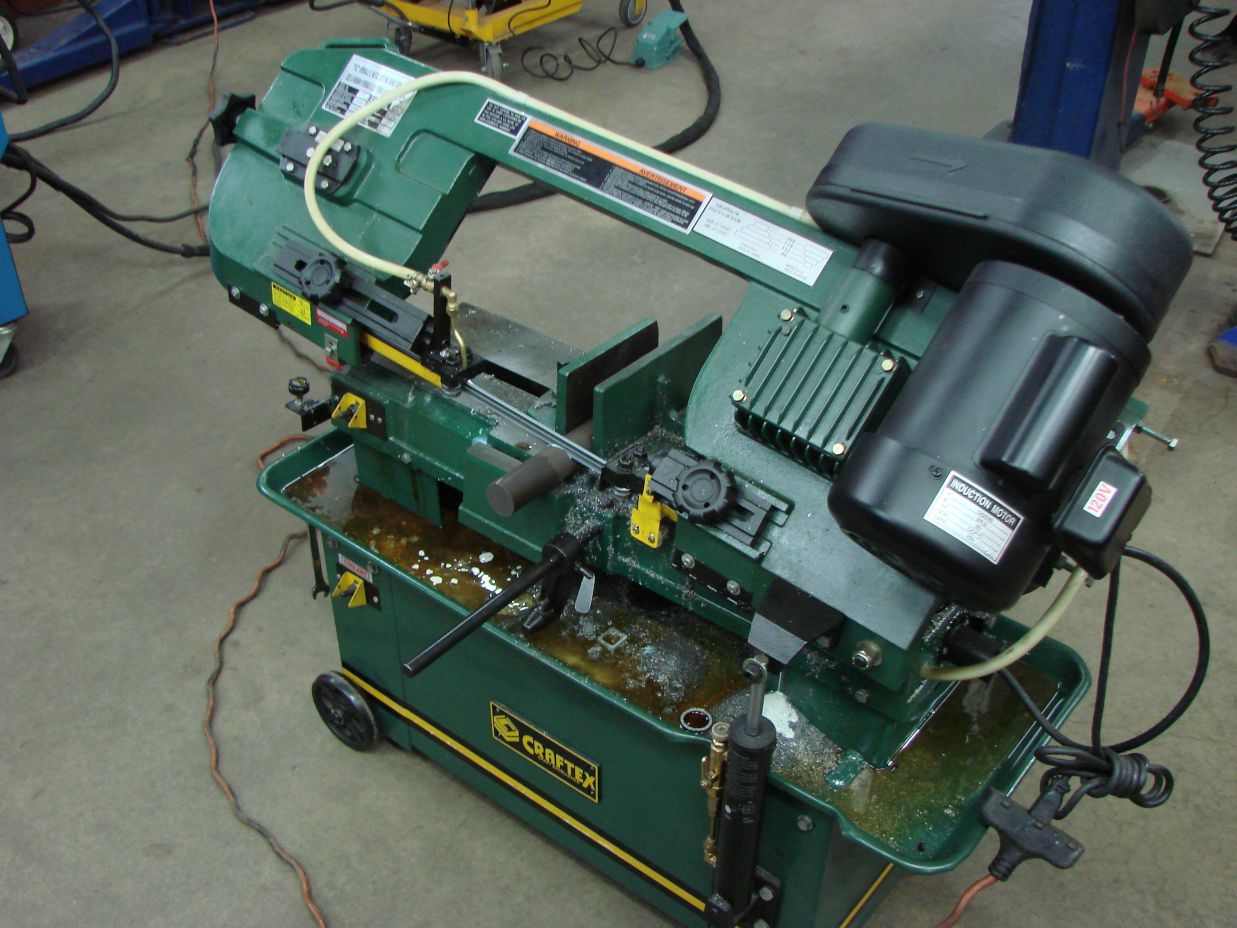

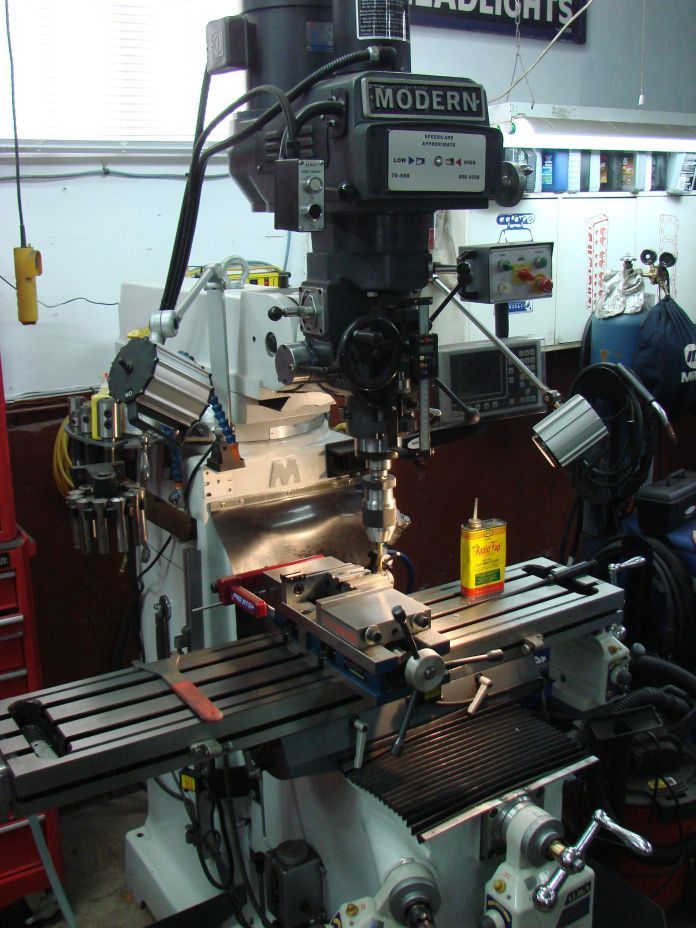

Equipment

Kubota L5740 HSTC3 and a Kubota ZG222Z, 2013 BX25D,Custom Toyota fork lift.

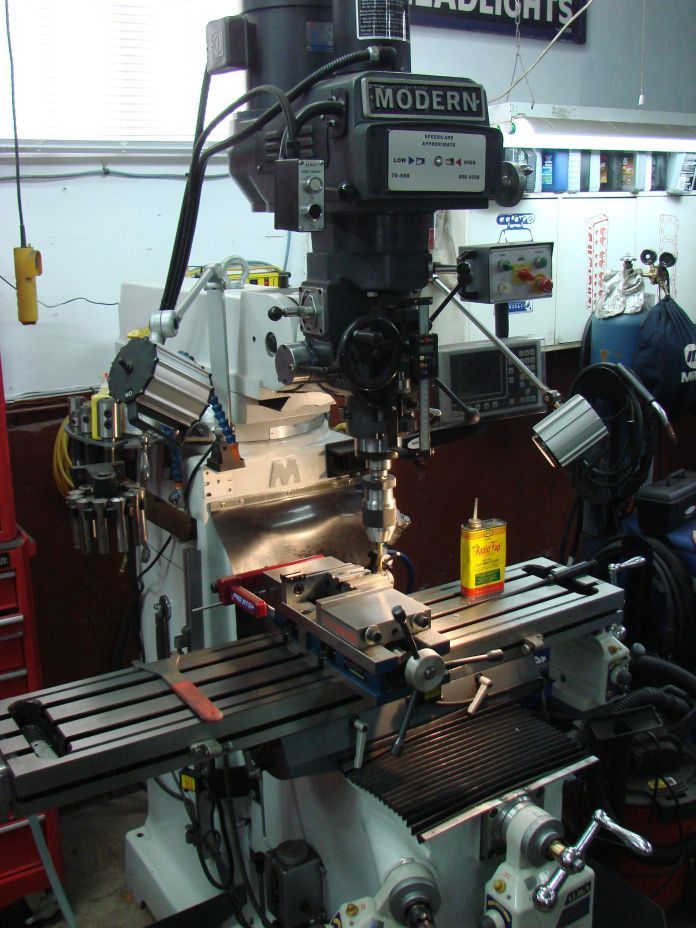

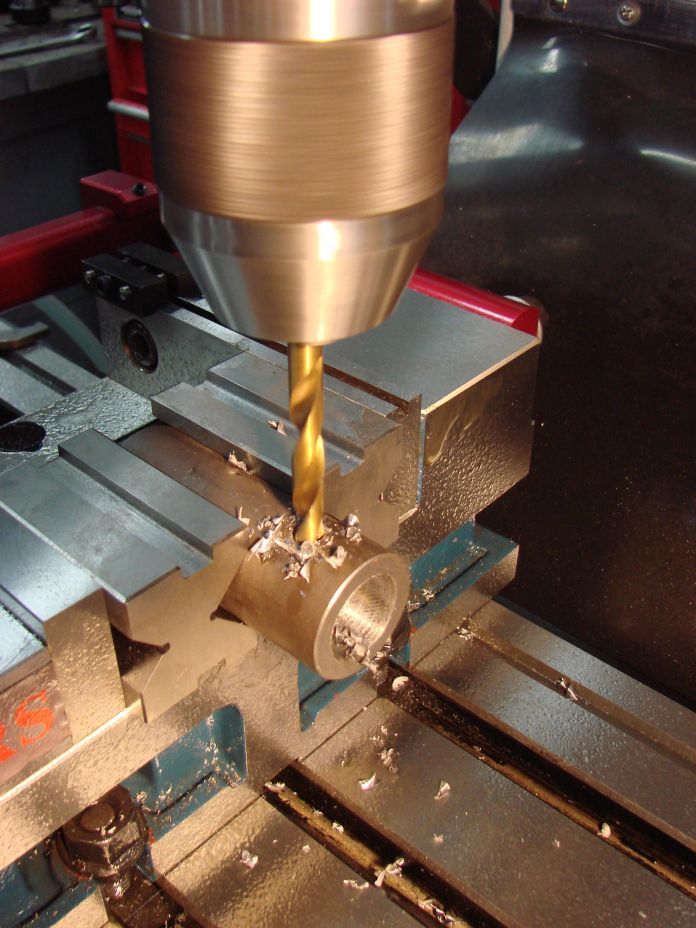

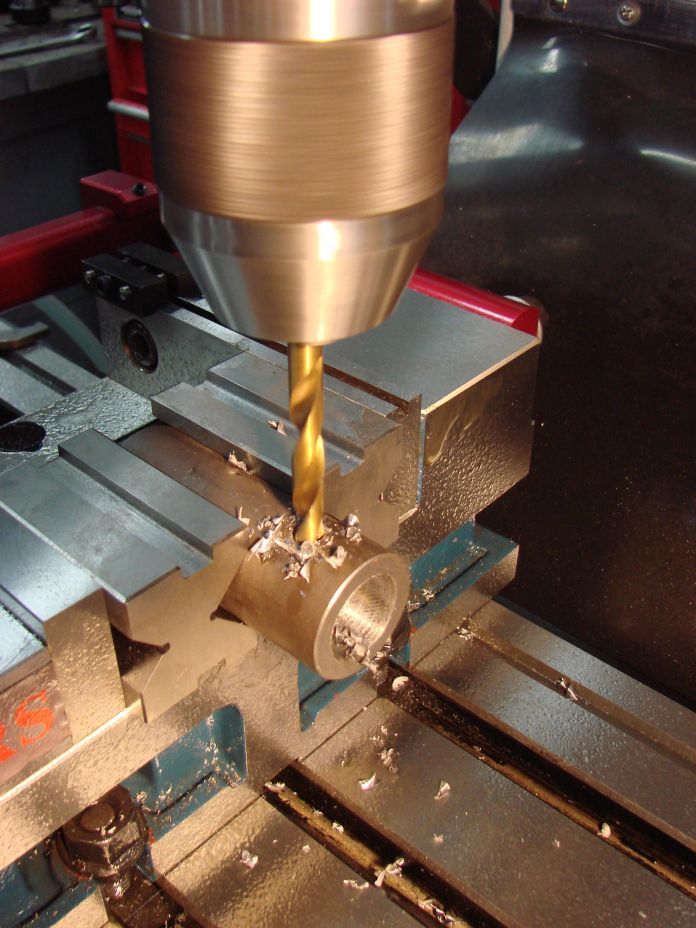

I thought I'd show you the steps it takes to do a simple hub for a lime spreader. It's nice for those who aren't used to getting something made to see the tooling and time that goes into fabricating a part. Enjoy!